Section 07 REAR SUSPENSION

Subsection 06 (TRACK)

07-06-1

TRACK 5

TRACK TYPE APPLICATION

Refer to TECHNICAL DATA section 10-03.

GENERAL

This section gives guidelines for track removal.

Some components require more detailed disas-

sembly procedures. In these particular cases, re-

fer to the pertaining section in this manual.

INSPECTION

Visually inspect track for:

– cuts and abnormal wear

– broken rods

– broken or missing track cleats

If track is damaged or rods are broken, replace

track. For damaged or missing cleats, replace by

new ones, using cleat remover (P/N 529 0287 00).

Use small-cleat installer (P/N 529 0085 00).

REMOVAL

S-Series

Remove the following parts:

– speedometer cable

– muffler

– chaincase cover

– suspension

– drive axle seal

– end bearing housing

– sprockets and chain

– drive axle (toward end bearing housing)

– track

Skandic WT/SWT/WT LC

Remove the following parts:

– rear suspension

– muffler

Drain gearbox.

Remove drive axle then track.

INSTALLATION

All Models

Reverse the removal procedure.

NOTE:

When installing the track, respect rotation

direction indicated by an arrow on track thread.

Check sprocket/track alignment as described in

DRIVE AXLE 07-05.

Track Tension and Alignment

Track tension and alignment are inter-related. Do

not adjust one without checking the other. Track

tension procedure must be carried out prior to

track alignment.

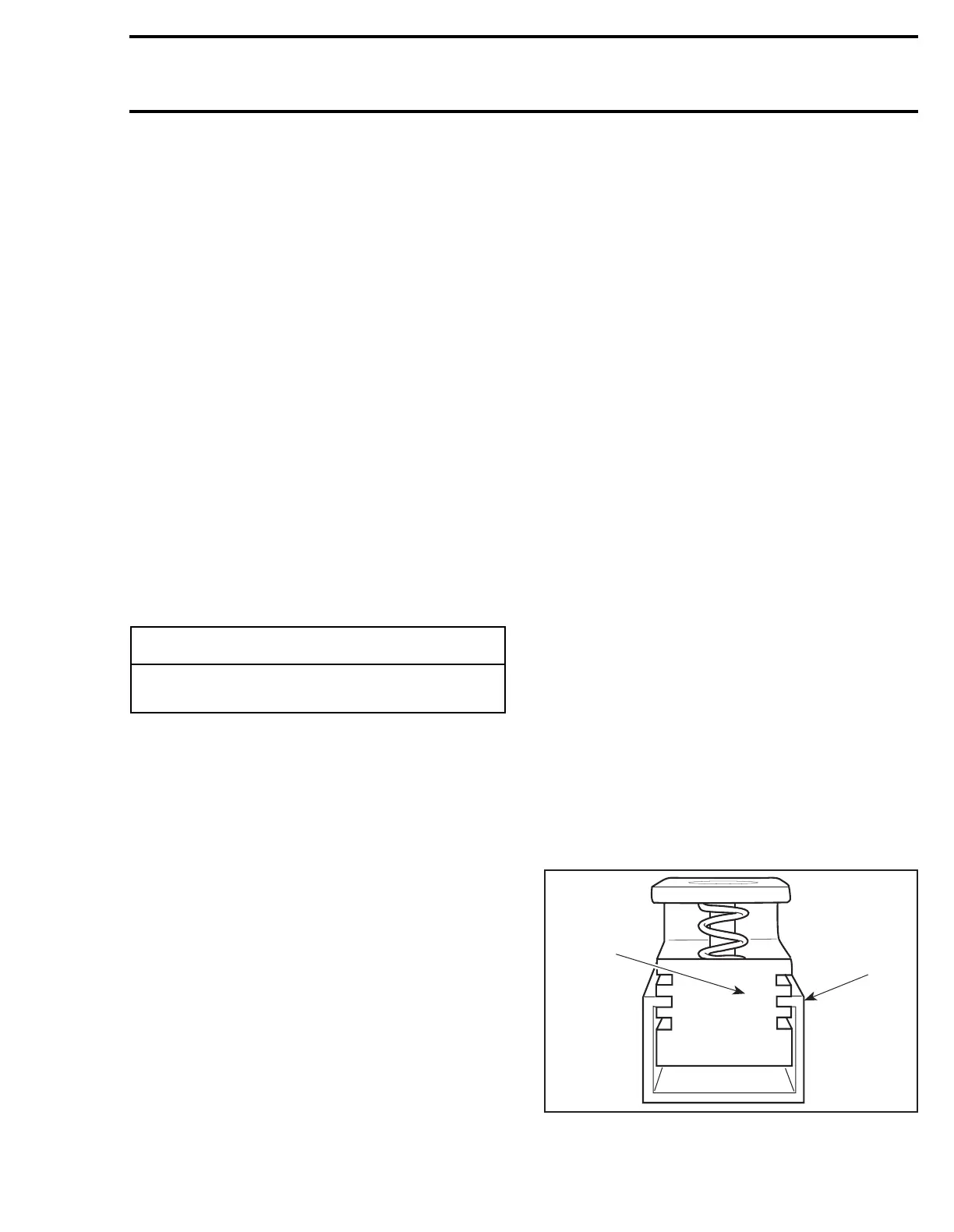

Tension

Lift the rear of vehicle and support with a mechan-

ical stand. Allow the slide to extend normally.

Check the gap halfway between front and rear

idler wheels. Measure between slider shoe and

bottom inside of track.

When using the track tension gauge (P/N 529

0215 00), slide U-shape extrusion to proper de-

flection. Refer to TECHNICAL DATA 10.

1. Example: 45 mm

2. Extrusion

◆

WARNING

Do not operate a snowmobile with a cut,

torn or damaged track.

40

45

50

A01B4JA

1

2

Loading...

Loading...