Section 04 ENGINE

Subsection 03 (494, 583 AND 670 ENGINE TYPES)

04-03-6

NOTE:

Oil dripping from draining hole indicates a

loosened clamp or damaged bellows.

Check for cracked, dried or perforated bellows

no. 9

.

6, Spring

Make sure both springs installed on the engine

have same characteristics.

ASSEMBLY

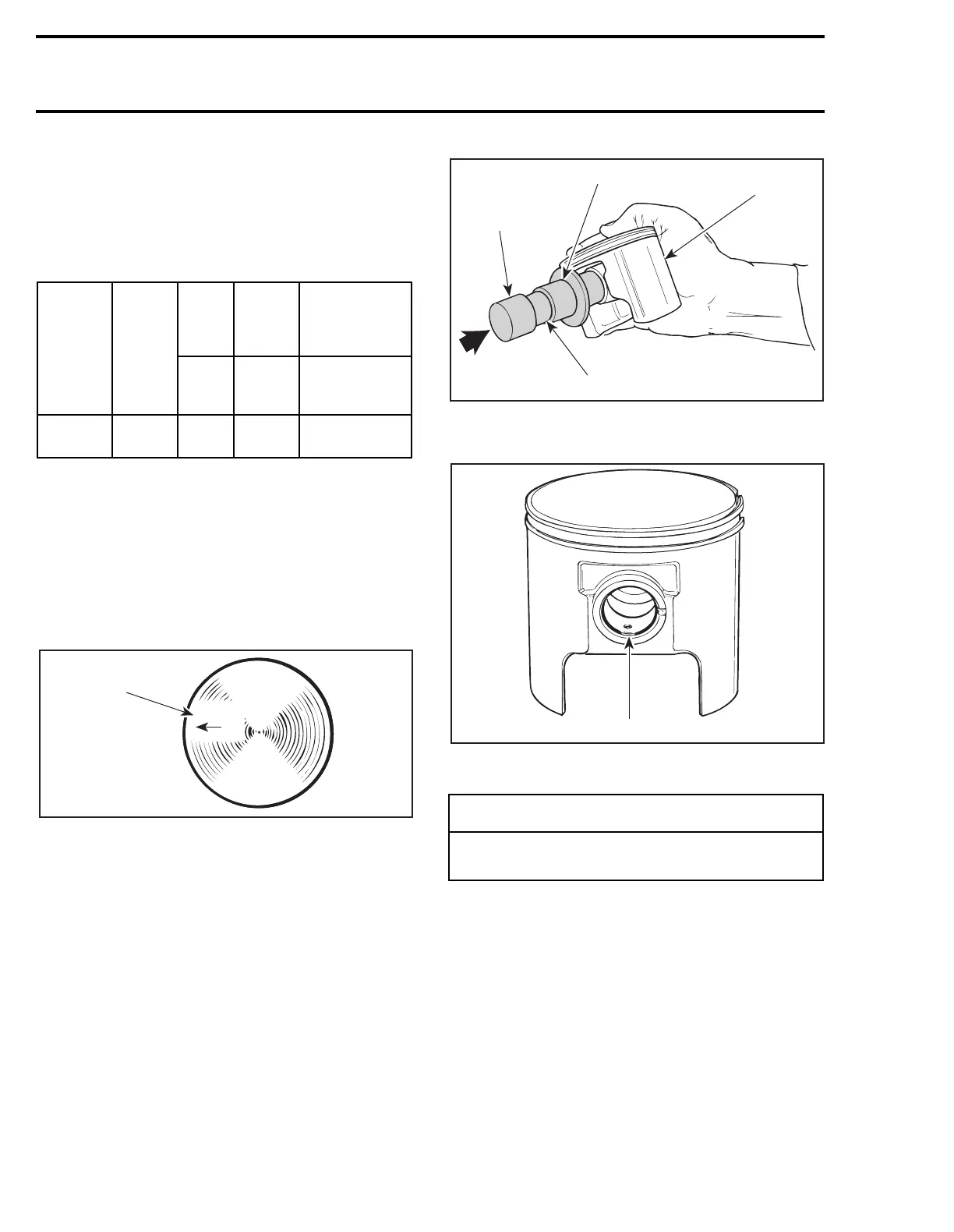

At assembly, place the pistons over the connect-

ing rods with the letters

AUS

(over an arrow on

the piston dome) facing in direction of the exhaust

port.

1. Exhaust

Use piston pin puller (P/N 529 0210 00) to ease

piston pin installation.

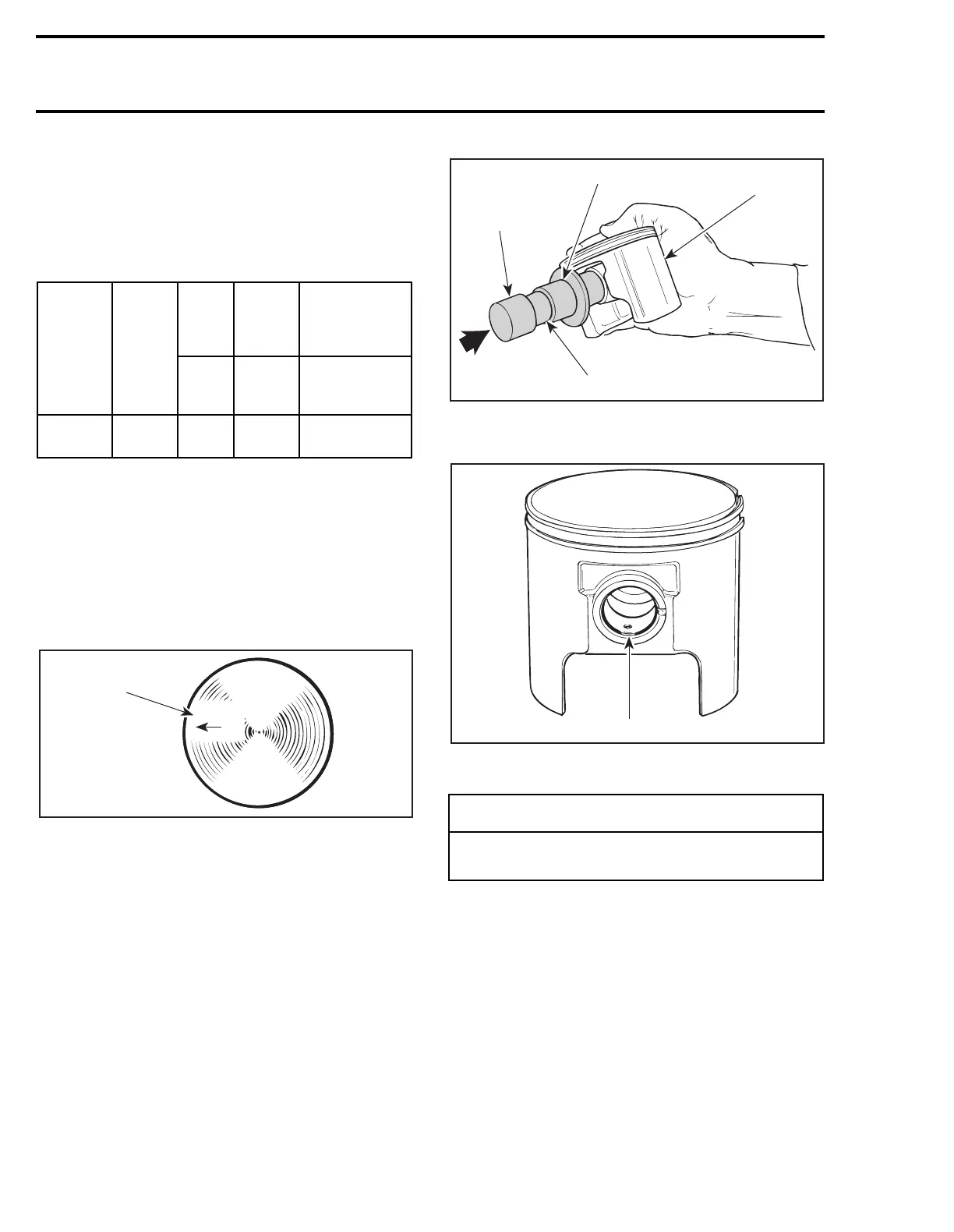

To minimize the effect of acceleration forces on

circlip, install each circlip so the circlip break is at

6 o’clock as illustrated. Use piston circlip installer

(P/N 529 0169 00) for all engines except 670 and

(P/N 290 8770 16) for 670 engine.

1. Place circlip in

2. Restrain

3. Oil

TYPICAL

1. Circlip break

22, Cylinder

494 Only

To avoid pinching or cutting of O-ring

no. 18

be-

tween cylinder and cylinder head, it is necessary

to use a special tool and to proceed as follows:

Use aligning pin (P/N 529 0189 00).

ENGINE

TYPE

SPRING

P/N

WIRE

DIA.

FREE

LENGTH

PRELOAD IN

N (LBF) AT

COMPRESSED

LENGTH

mm

(in)

mm

(in)

OF

14.7 mm

(.579 in)

583

and 670

420

2399 48

1.0

(.039)

38.0

(1-1/2)

0.0163

(.00365)

A01C01A

AUS

1

-

CAUTION

Circlips must not move freely after installa-

tion; if so, replace them.

A01B1QA

1

2

3

529 0169 00

1

A01C02B

Loading...

Loading...