HRX-OM-Q026

Chapter 7 Control, Inspection and Cleaning

HRSH Series 7.2 Inspection and Cleaning

7-5

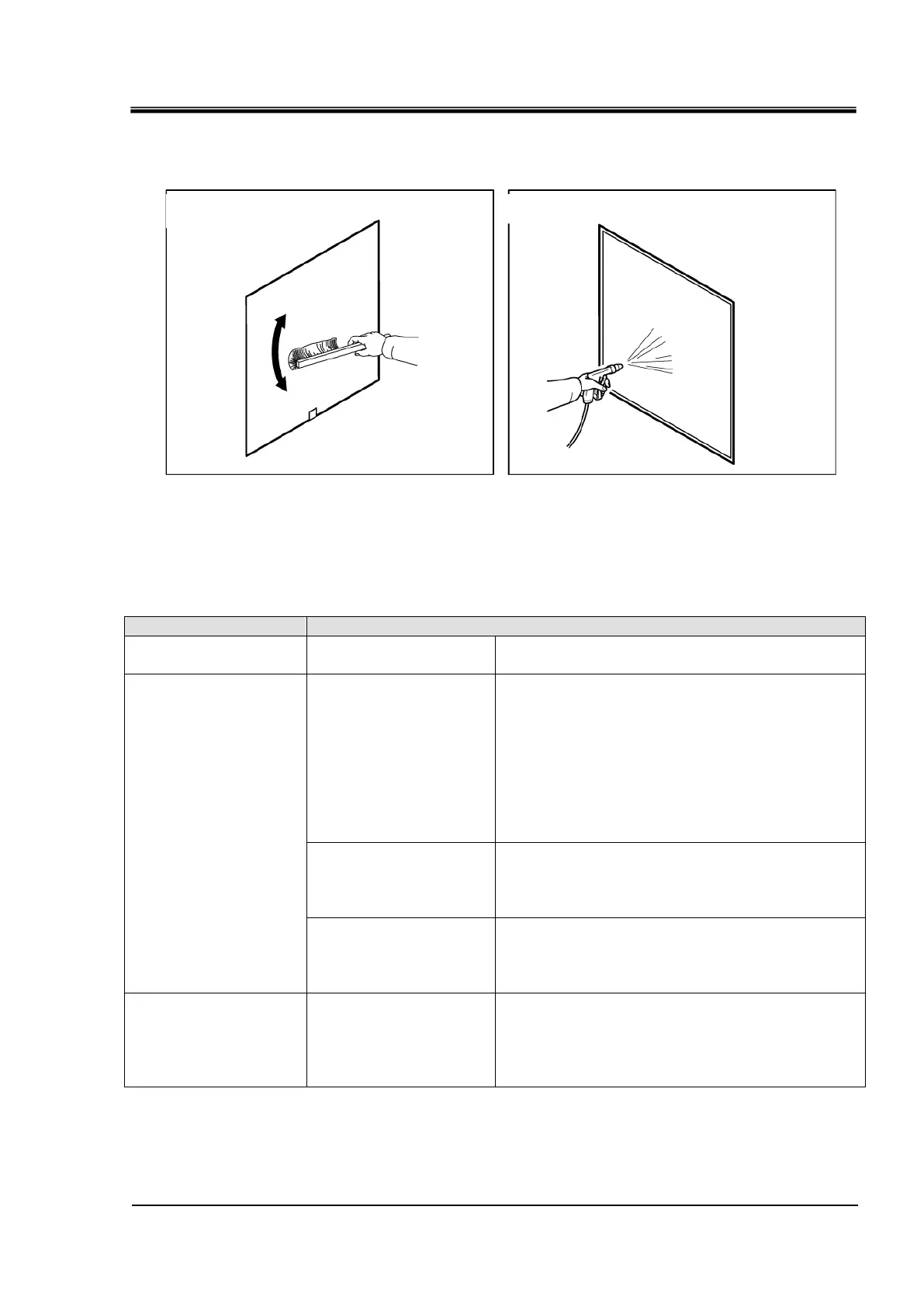

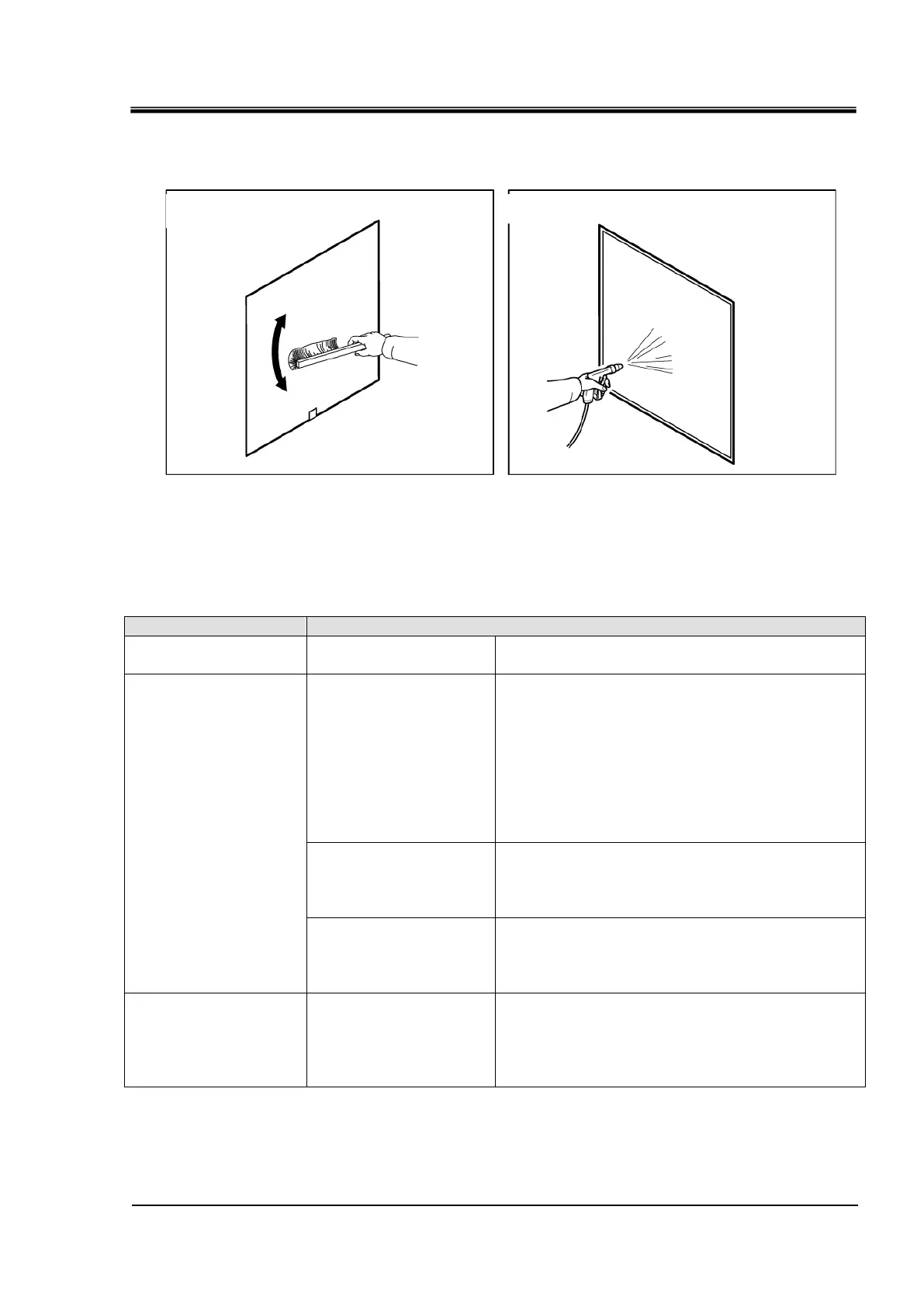

◼ Cleaning of dust-proof filter

Clean the dust-proof filters with a long bristled brush or by air blow.

Fig. 7-2: Cleaning of the dust-proof filter

◼ Mounting of dust-proof filters

Reassemble the filters in the reverse order to the removing procedure.

7.2.3 Inspection every 3 months

Table 7-4 Contents of every 3 months check

Check the power supply

voltage.

- Make sure the supply voltage is within the specification

range.

Replace the circulating water

(clean water) periodically.

- Ensure that the water has not been contaminated and

that there is no algae growth.

- Circulating water inside the tank must be clean and there

must not be foreign matter inside.

- Use clean water or pure water. The water quality must

be within the range shown in Table 7-1 Quality criteria

for clean water (tap water).

* It is recommended to replace the circulating fluid every 3

months when periodic maintenance is performed.

Density control

(When using 15%

concentration ethylene

glycol aqueous solution)

- Density must be within the range of 15 % +5/-0.

Density control

(When using 40%

concentration ethylene

glycol aqueous solution)

- Density must be within the range of 40 % +5/-0.

Facility water

(For water-cooled type)

- Ensure that the water is clean and contains no foreign

matter. Also check that the water has not been

contaminated and there is no algae growth.

- The water quality must be within the range shown in

Table 7-1 Quality criteria for clean water (tap water).

Loading...

Loading...