MS 500i 61

N Position arm (21) so that the spindle (20) lines up with

the crankshaft stub (4) and the screws (22 and 24) fit

squarely in the tapped holes (arrows) in the

crankcase (2).

N Fit screw (24) in the M4 tapped hole (arrow) in the

crankcase (2).

N Fit screws (22) in the M5 tapped holes (arrows) in the

crankcase (2).

N Fit the screws (22 and 24) so that the spindle (20) is

in line with the crankshaft stub.

N Turn the spindle (20) clockwise until the crankshaft

(4) is pushed out of the crankcase (2).

N Take out the screws (22 and 24) and remove the

puller 5910 890 4505.

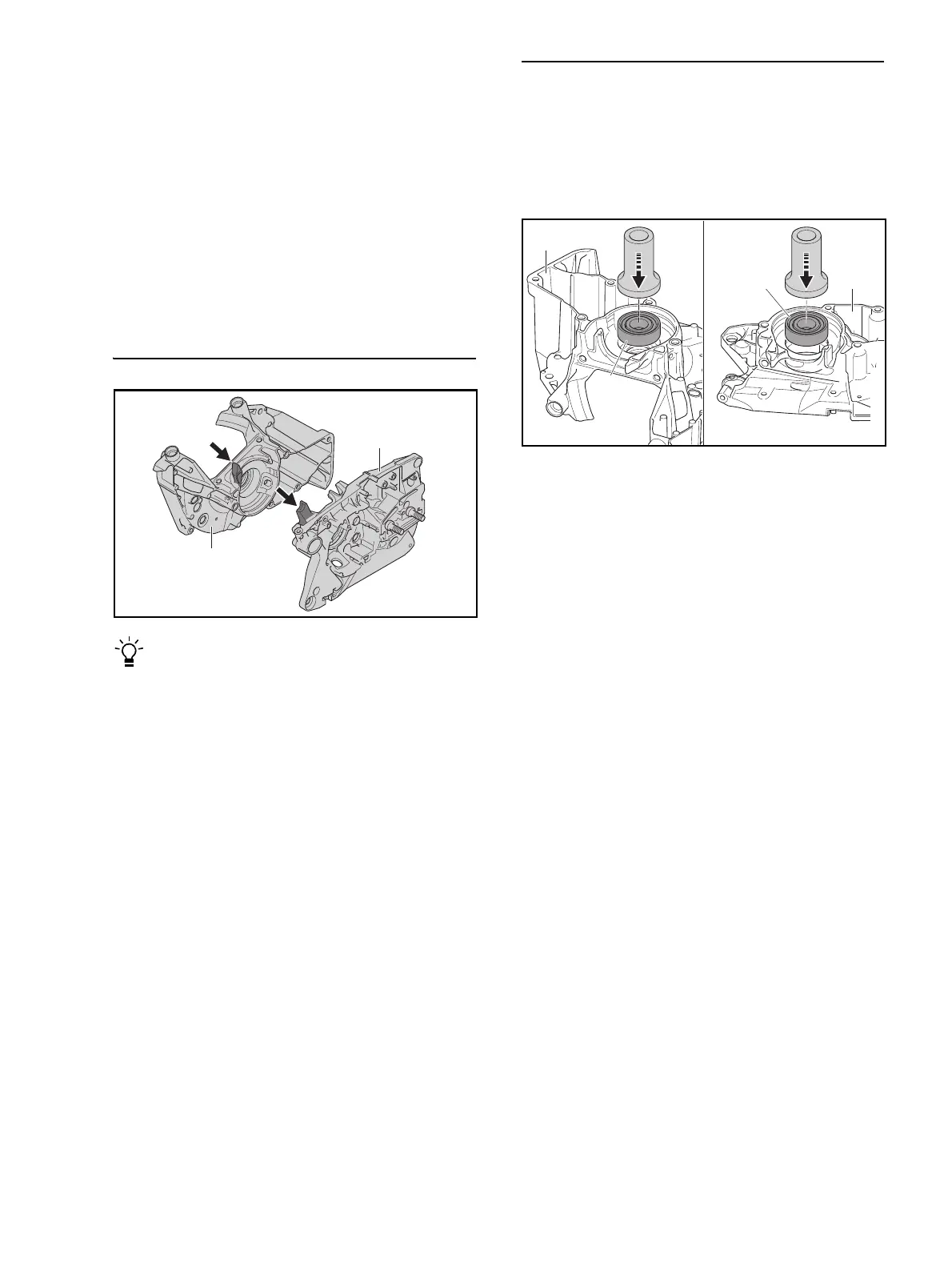

28.5 Removing the Ball Bearings

The scavenging ramp on the crankcase can be damaged

while removing the ball bearings. A damaged scavenging

ramp can result in serious engine damage.

Remove ball bearings so that the two halves of the

scavenging ramp (arrows) on the two halves of the

crankcase (2 and 7) are not damaged.

N Disassemble crankcase and remove crankshaft, @

28.4.

N If the two halves of the scavenging ramp or the two

halves of the crankcase (2 and 7) are damaged,

replace the crankcase (2 and 7).

N Put the two halves of the crankcase (2 and 7) down

so that the ball bearings (3 and 5) can drop out.

N Heat the two halves of the crankcase (2 and 7) in

bearing seat area to about 180°C (350°F).

N If the ball bearing (3) does not drop out of its own

accord: Use press sleeve 1113 893 4600 to remove

the ball bearing (3).

N If the ball bearing (5) does not drop out of its own

accord: Use press sleeve 4119 893 2400 to remove

the ball bearing (5).

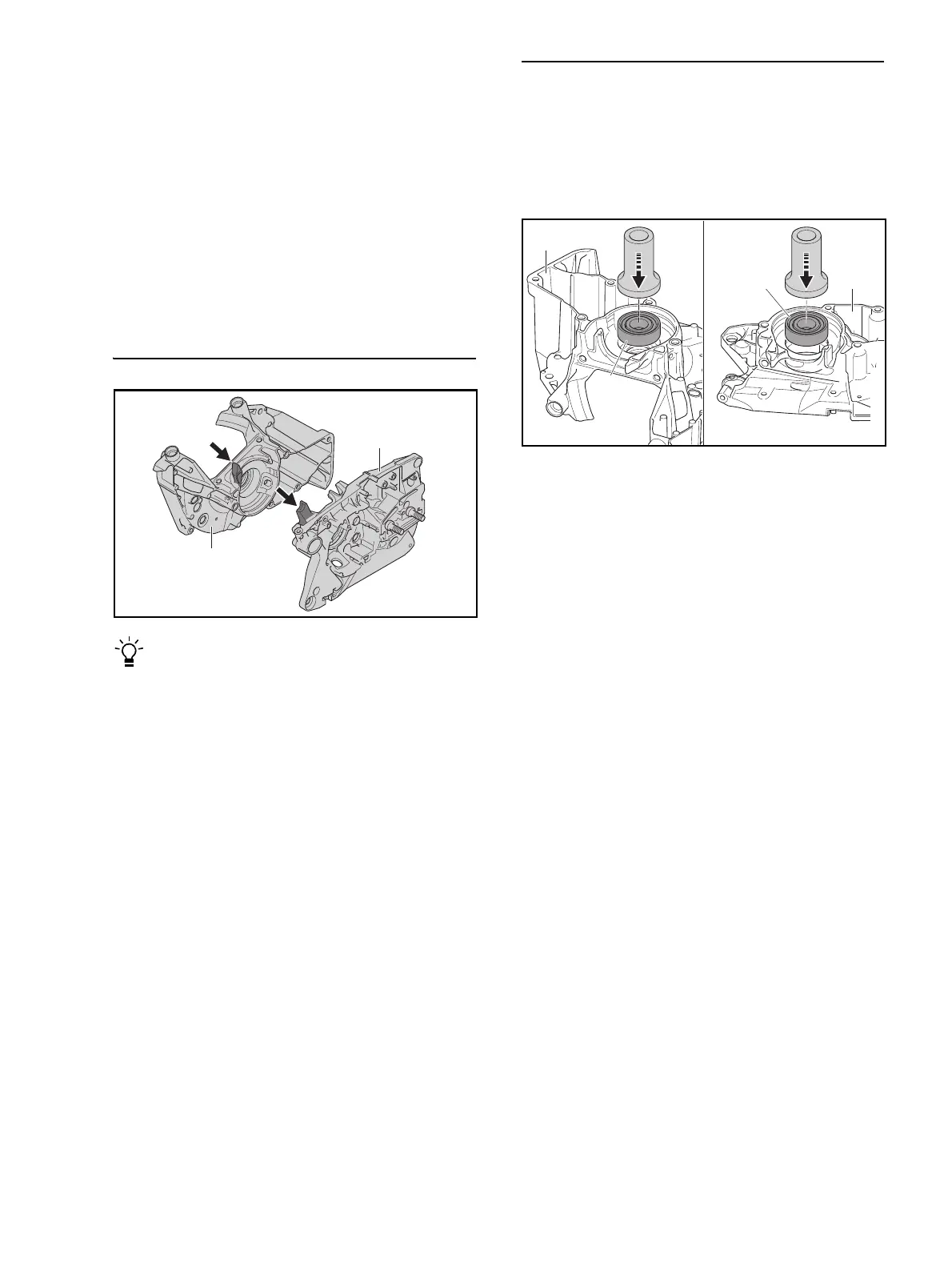

28.6 Installing the Ball Bearings

N If the two halves of the scavenging ramp in the

crankcase (2 or 7) are damaged, replace the

crankcase (2 or 7), @ 28.5.

N Install the oil pump, @ 14.10.

The oil pump serves as a stop when installing the ball

bearing (5).

N Line up the ball bearing (3) so that its closed side

(balls not visible) faces the crankcase (2).

N Line up the ball bearing (5) so that its open side (balls

visible) faces the crankcase (7).

N Heat the two halves of the crankcase (2 and 7) in

bearing seat area to about 180°C (350°F).

N Push home the ball bearings (3 and 5) as far as stop.

N If the ball bearings (3 and 5) cannot be pushed home:

Use press sleeve 4119 893 2400 to press home the

ball bearings (3 and 5).

N If ball bearing (5) does not butt against the oil pump:

Use press sleeve 4119 893 2400 to press home ball

bearing (5) until it butts against the oil pump.

N Remove the oil pump, @ 14.5.

2

7

0000-GXX-5654-A0

3

2

75

0000-GXX-5657-A0

Loading...

Loading...