ReferenceN-10

Notes

10MAY01

Using An Anti-Seize Lubricant To Extend

The Life of FDM Liquefiers

Using an anti-seize lubricant will help extend the life of all models of FDM

liquefier. Applying a high temperature anti-seize lubricant to the FDM mod-

eler tip‘s threads will prevent cold welding of the tip to the steel threads of

the FDM Head.

Before applying the lubricant, review the following usage and application in-

structions. If necessary, refer to your FDM operations manual for additional

information on changing and inserting FDM tips into the FDM head.

Recommended Usage

Only use a light coat of an anti-seize lubricant when:

• you need to insert a new tip in a liquefier for the first time

or

• when you need to replace a tip with a new or used tip

Follow the standard tip removal procedures, as outlined in your FDM

documentation. Also, do not remove a tip only to apply the anti-seize

lubricant.

Recommended Application

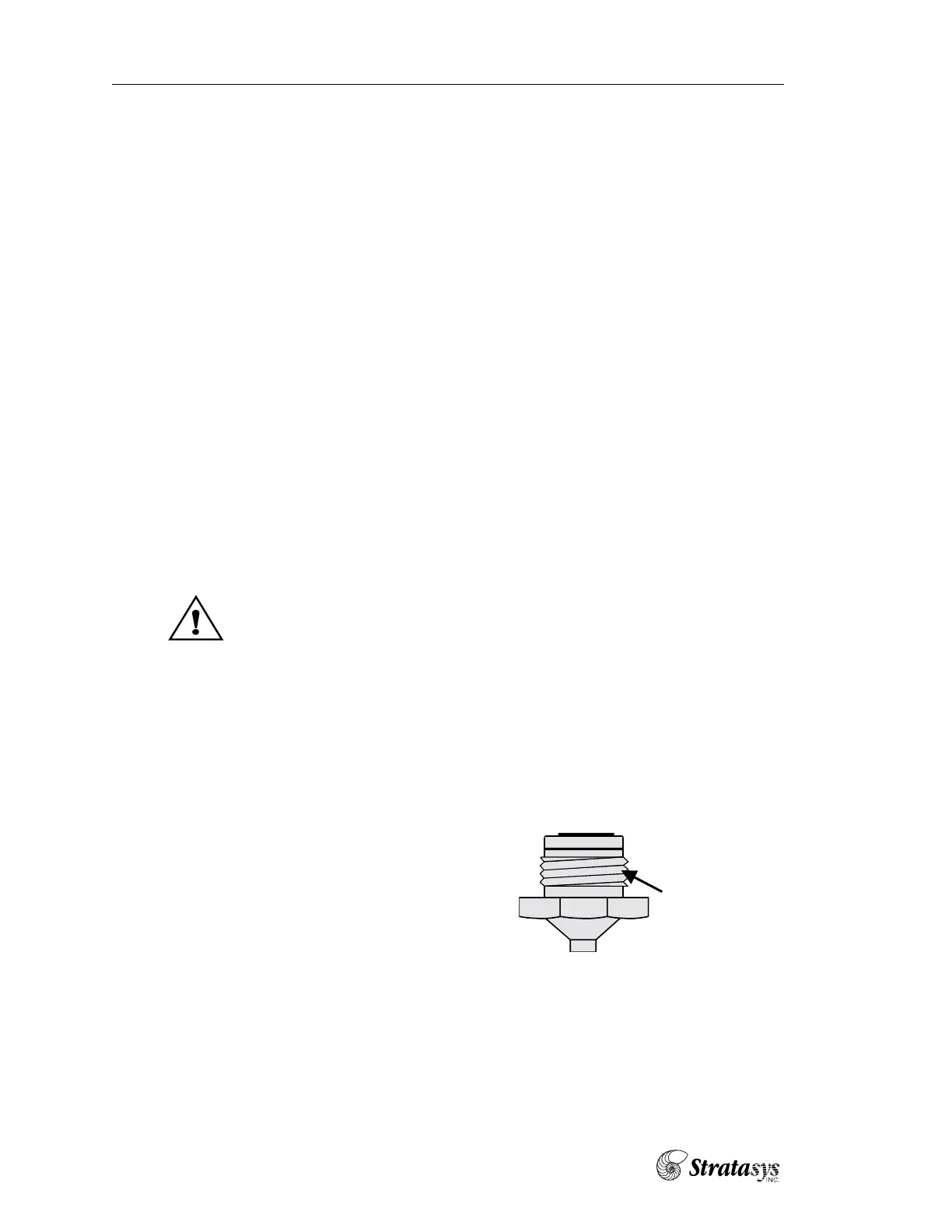

• Be sure to apply the anti-seize lubricant to the tip’s threads prior to thread-

ing the tip into the liquefier.

• Apply the lubricate to the tip’s threads, not the aluminum threads within the

FDM head.

• Apply a thin coat of lubricant to the

grooves of the tip’s thread.

You don’t need to completely coat the

threads.

• If you apply too much, purge the excess

lubricant from the tip.

Note: Use high temperature, anti-seize lubricants designed to prevent seizing,

galling, and corrosion. These lubricants are easily obtained from most automo-

bile parts and supply stores. If you have additional questions, please call

Stratasys Customer Service at 952-906-2283.

Apply a thin

layer of lubricant

to the tip's threads

Loading...

Loading...