Reference N-11

Notes

10MAY01

Technical Notes

Modeling with the T10 Tip (0.010-inch)

The T10 tip (0.010-inch) is designed for small, thin-walled, fine featured or

highly detailed parts. When used with the .007-inch slice increment, superior

surface is also achieved. The T10 tip is currently available on the FDM 2000/

3000/8000.

T10 Features

Features of the T10 tip include:

• A .01-inch inside diameter and a .03-inch

outside diameter.

• Use of a smaller nozzle outside diameter to

improve the modeling of small features.

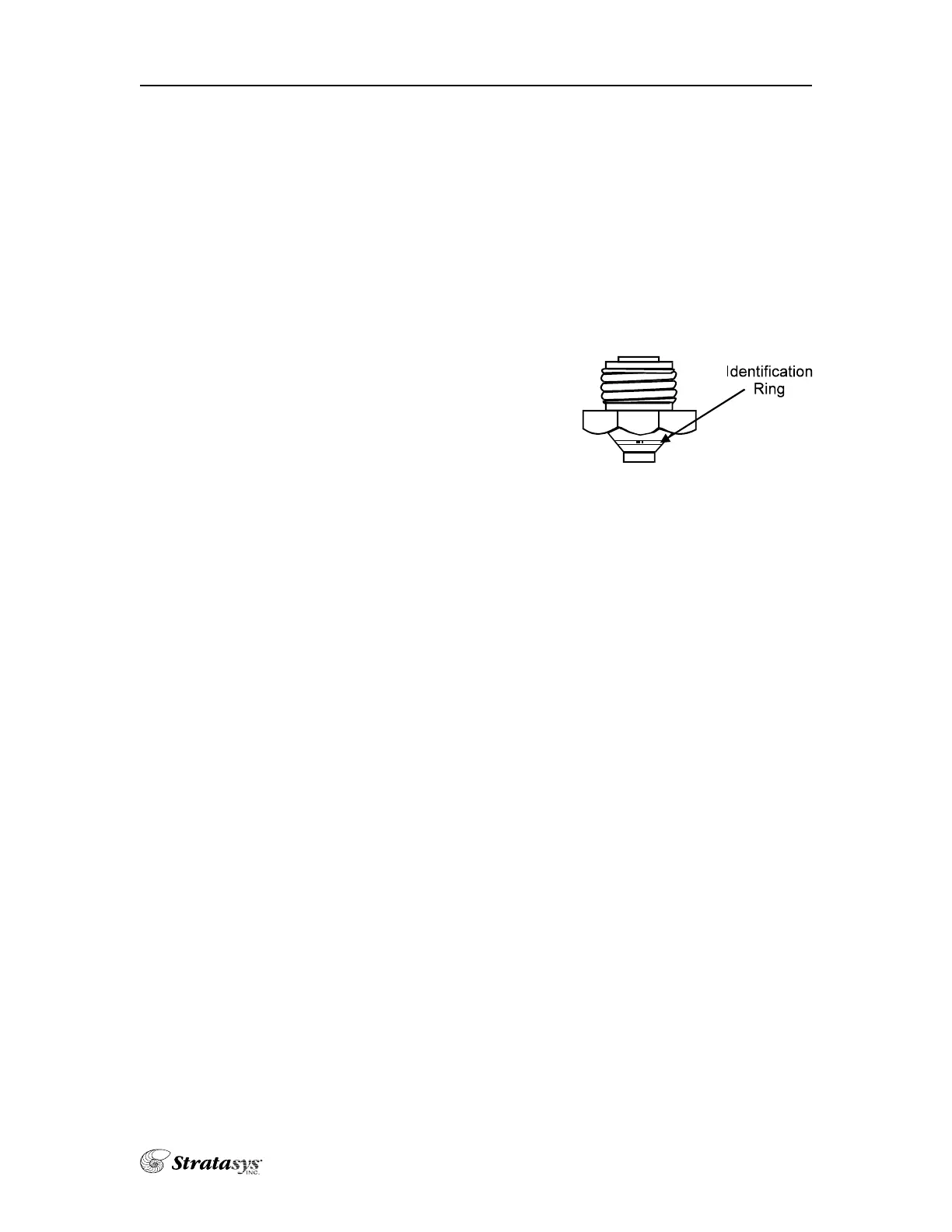

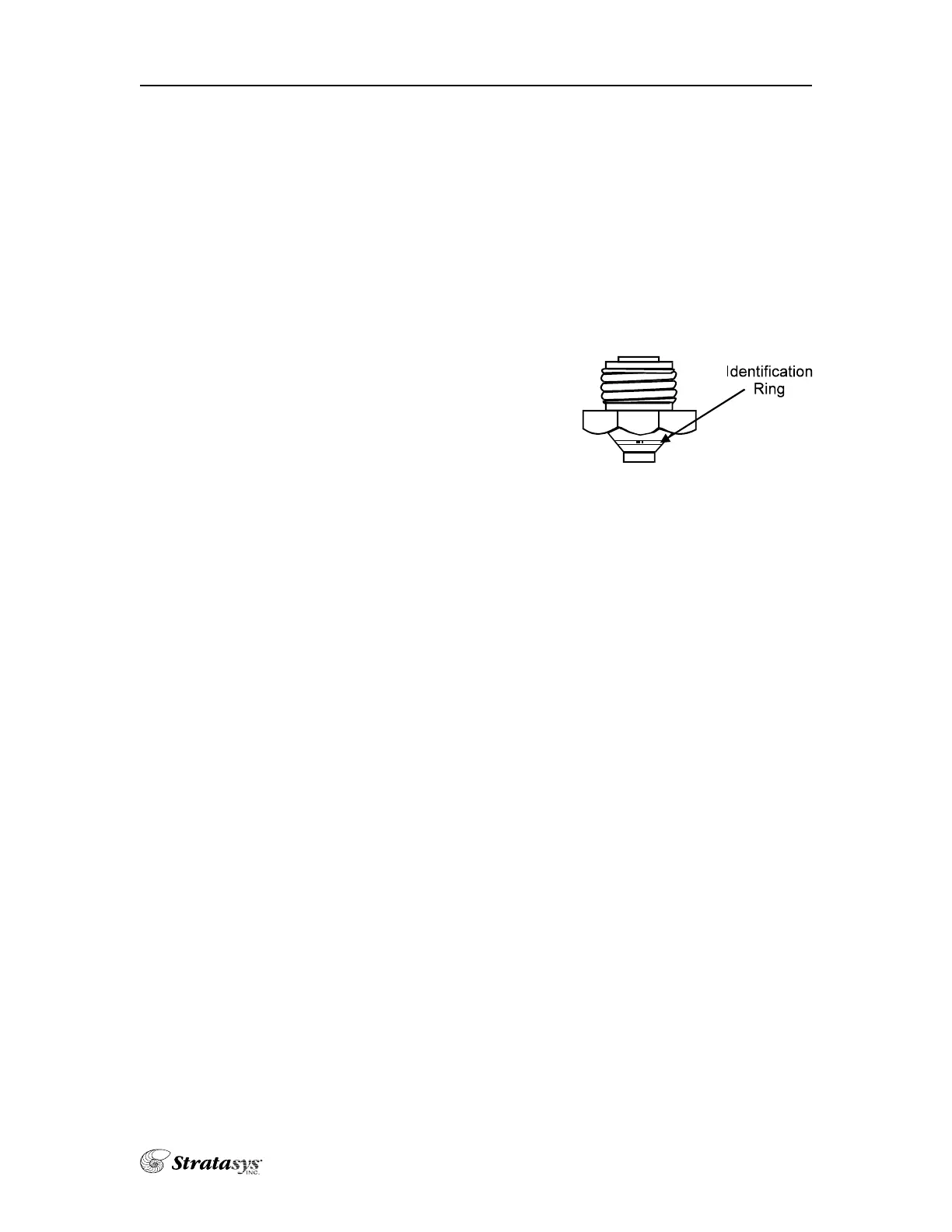

• An identification ring engraved into the tip

for easy identification.

• .007 and .010 Def files

Setup Procedures Unique to the T10 Tip

• For ABS material, set the model liquefier temperature at 290°.

• Use the T10 tip for the model side and T12 for the support side.

• Set the envelope temperature at 60°. Parts that are less than 1.5”sq. can run

with a 50° envelope.

• Use of a run speed of 1 inch per second for all curves.

• Use a contour and raster toolpath width range between .01 – .028 inches.

• Run the calibration procedure whenever you change a tip. Proper calibra-

tion is very important, particularly in the Z-axis. If necessary, refer to the

calibration procedures in the hardware section of your FDM manual.

• Purge the model side liquefier prior to running a model (let the model side

load until the “load time fault” flashes on the key pad screen).

• Run parts in the center of the foam when possible.

Single

Loading...

Loading...