Reference N-13

Notes

10MAY01

Technical Notes

FDM Maintenance Tips

FDM XY Table Lubrication

The following procedures describe how to lubricate the FDM 8000 XY table.

Even though your FDM was lubricated at the factory, you should lubricate the

XY table monthly to ensure continued, optimal performance. If you have

questions about the procedure contact Stratasys customer support at 952-

906-2283.

Before You Start

The supplied lubrication kit includes a grease gun that contains a special-

ized lubrication and grease gun fitting. In most cases you should not have to

replace the lubricant or fitting. If you do, you must use a synthetic lubricant

with teflon suspension and a temperature rating of 425° F. In addition, the

grease fitting is a flush miniature type—a standard fitting will not work with

this procedure.

WARNING! The interior components of the FDM are hot! Prior to

greasing, lower the temperature of the model, support and envelope

Watlows to zero degrees, and wait for the FDM to cool down to a

safe working temperature. You can open the envelope door to

speed up the cooling process. To avoid injury, make sure you use

the safety gloves supplied with your lubrication kit.

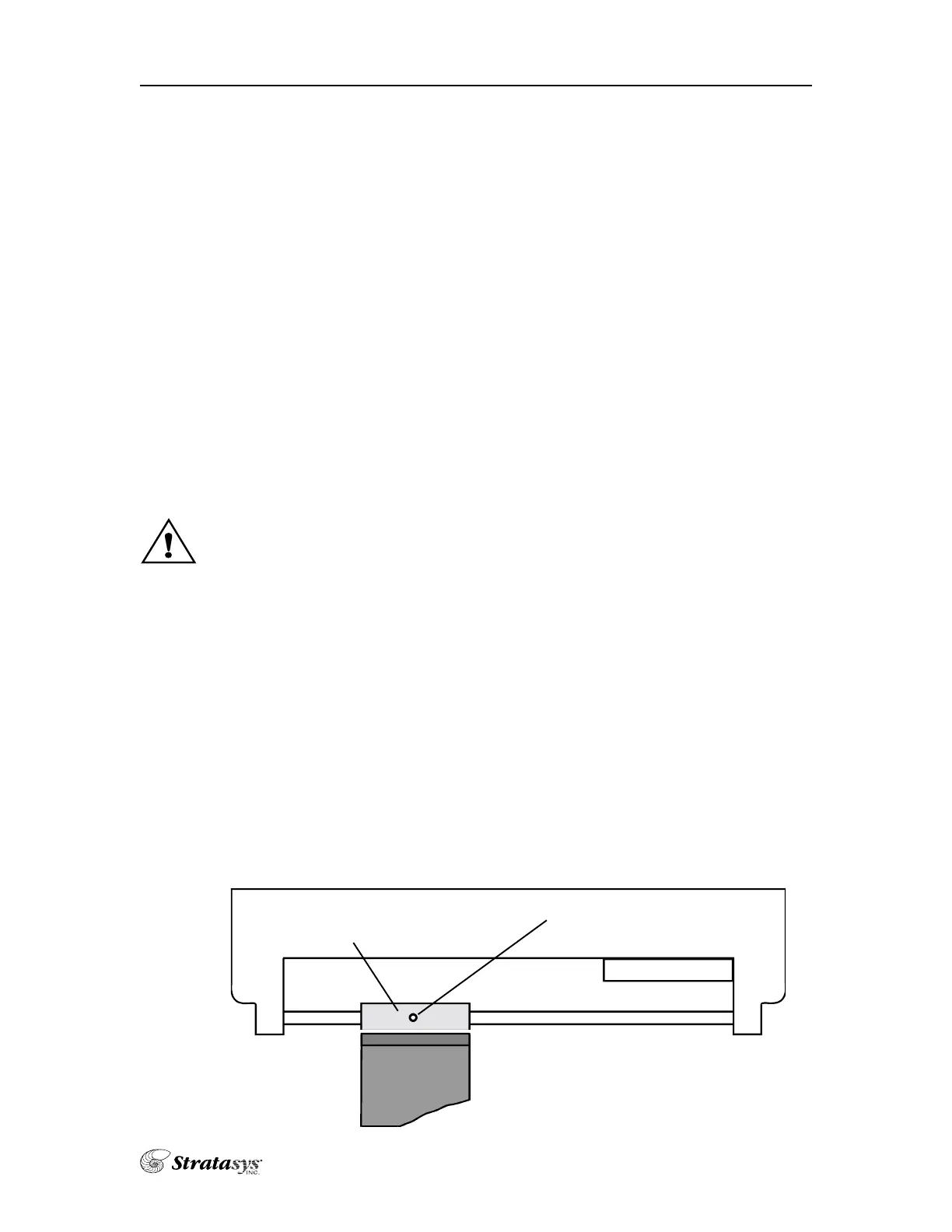

Step 1—Grease the Front X-axis Bearing on the 8000

1. Lower the Z-stage to the bottom of its travel path.

2. Remove the foundation tray and cover the Z-stage with a cloth, in case

grease falls onto the table.

3. With FDM 8000 power turned on, move the head to the rear and center of

the envelope.

XY Table

(front view)

Front grease

fitting

Front bearing

housing

Loading...

Loading...