© STULZ GmbH, Hamburg EN / 10-2015 / 1000683

-

73

-

STULZUltraSonic-SystemforDirectRoomHumidicationBNB- Maintenance

11.1. Maintenance cycles

Content of general maintenance checks:

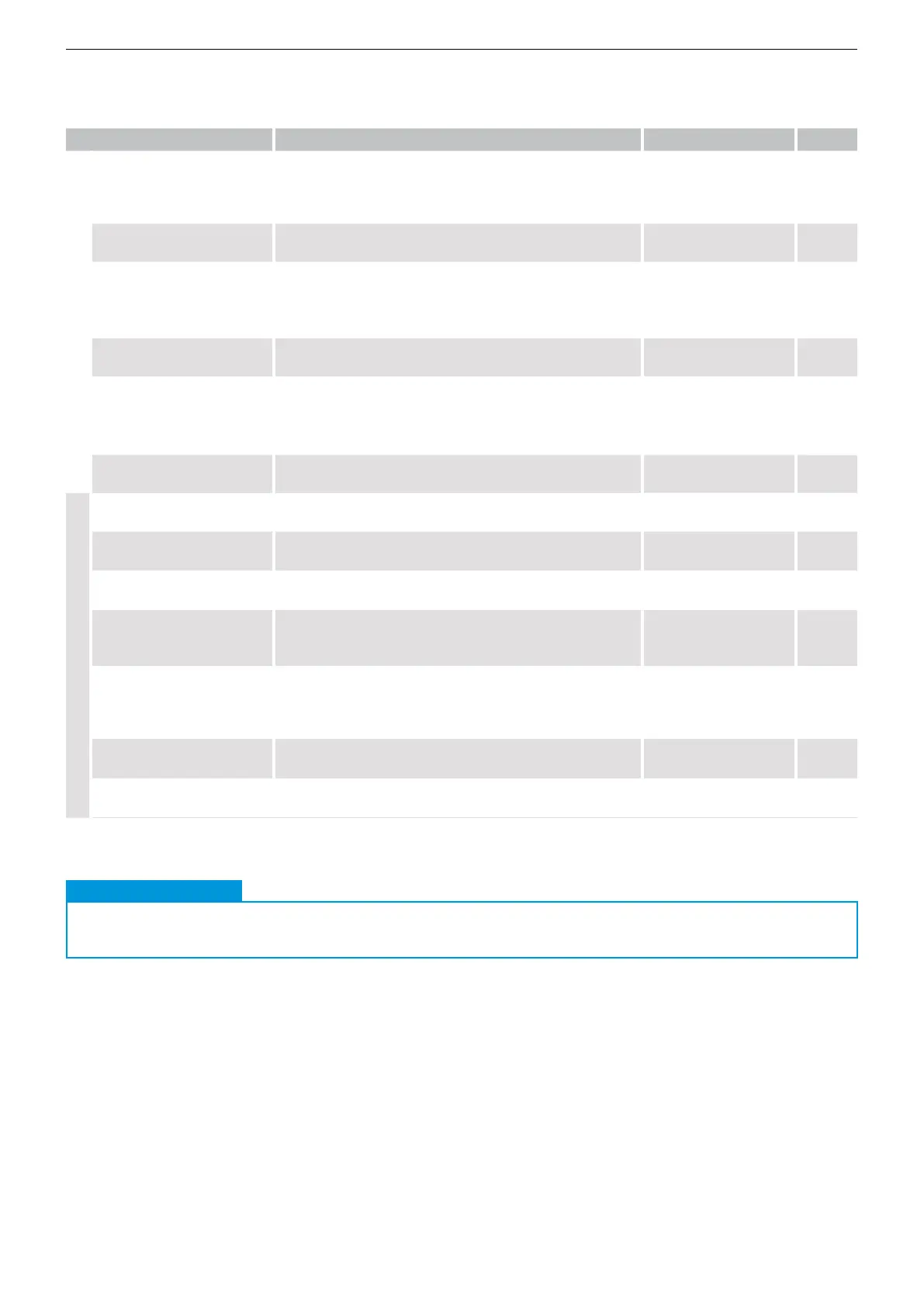

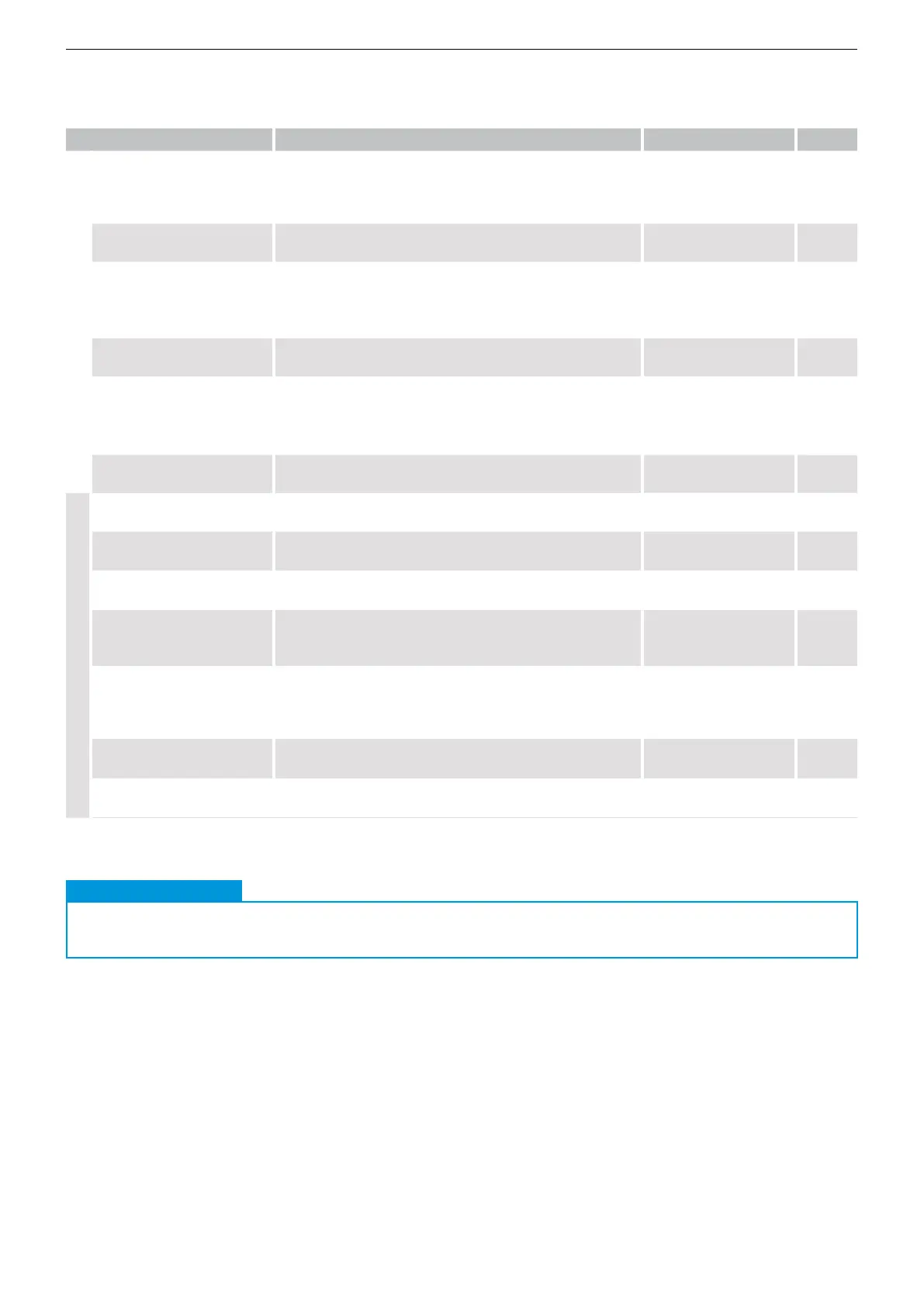

Job to be performed Scope of checks Time interval

1)

Page

Plant operator

Check for secure

connections

- Tightness of connections of water-bearing parts

-Cleannessoflter

- Water tank and outside of unit for impurities

- Humidity sensor and ventilation slots for impurities

3 months

Page

75

Mist guide tubes Check mist guide tube for deposits. 3 months Page

78

Clean the water tank Remove housing cover and retaining plate together with

mistowpipes(openwatertank),cleananddisinfect

with hydrogen peroxide solution.

6 months

Page

78

Cleantheairlter Openltercase,cleanlter. 6 months Page

77

Leak test Check all screw and push-in connections for leaks

- Threaded joints are secure

- Connectors are secure

6 months

Page

74

Transducers Check transducers for deposits. 6 months Page

78

Specialist engineer

Inspect electrical system Remove cover of control system and check electrics. 6 months Page

80

Replace nebulizer print

plates

---

Approx. every 10,000

operating hours

Page

88

Replace ultrasonic

humidier

---

In the event of prob-

lems or failure

Page

71

Replaceoat

switch for

supply pipe

---

Approx. every 10,000

operating hours

Page

84

Replaceoat

switch for

lower water level

---

In the event of prob-

lems or failure, every

10,000 operating

hours at the latest

Page

84

Replace relay PCBs

---

In the event of prob-

lems or failure

Page

82

Replace fan

---

In the event of prob-

lems or failure

Page

89

1)

Time intervals may be shorter in isolated cases, depending on local conditions.

1)

Visual inspections must be performed regularly!

CAUTION

Time intervals of maintenance cycles

.

The time intervals of maintenance cycles may have to be adapted to suit local conditions.

NOTICE

Loading...

Loading...