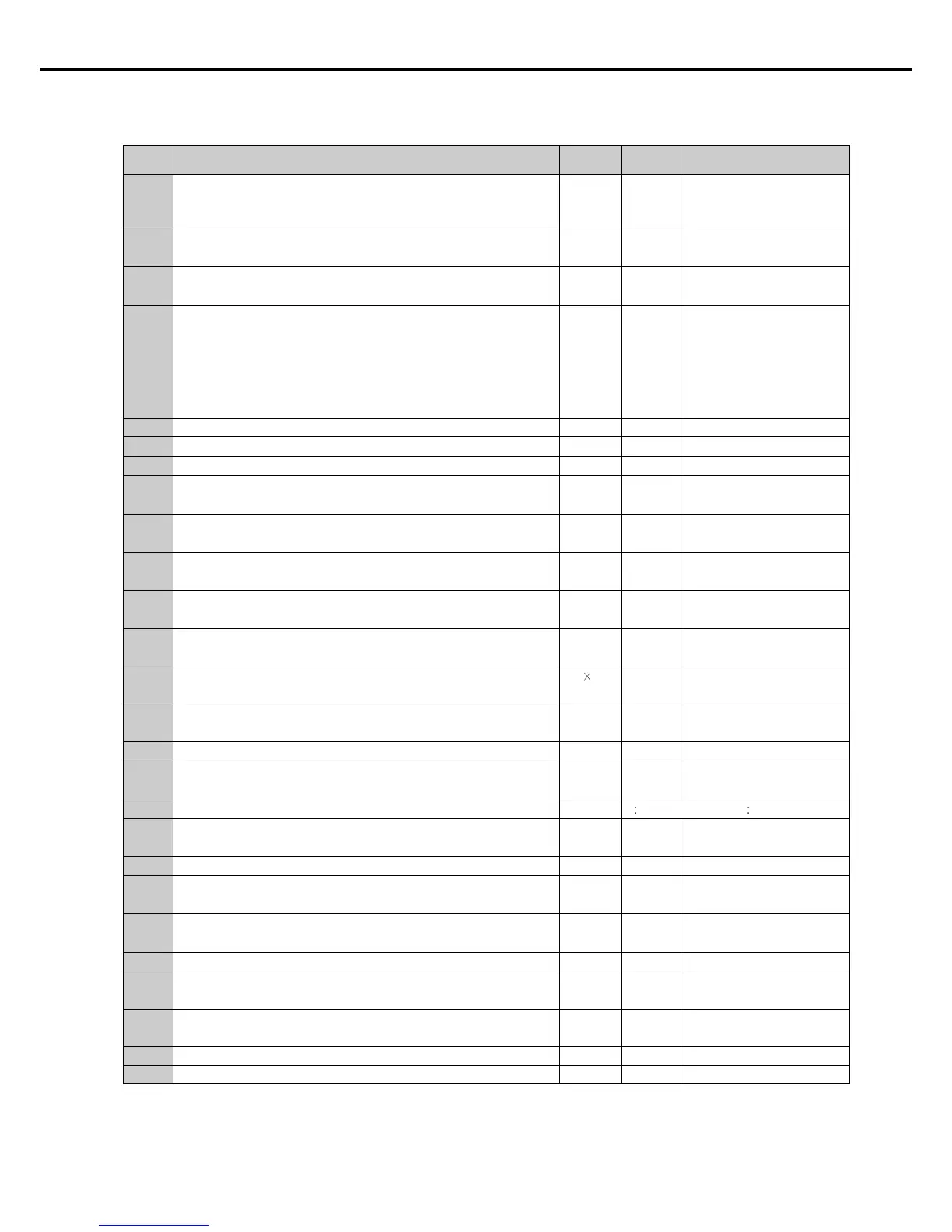

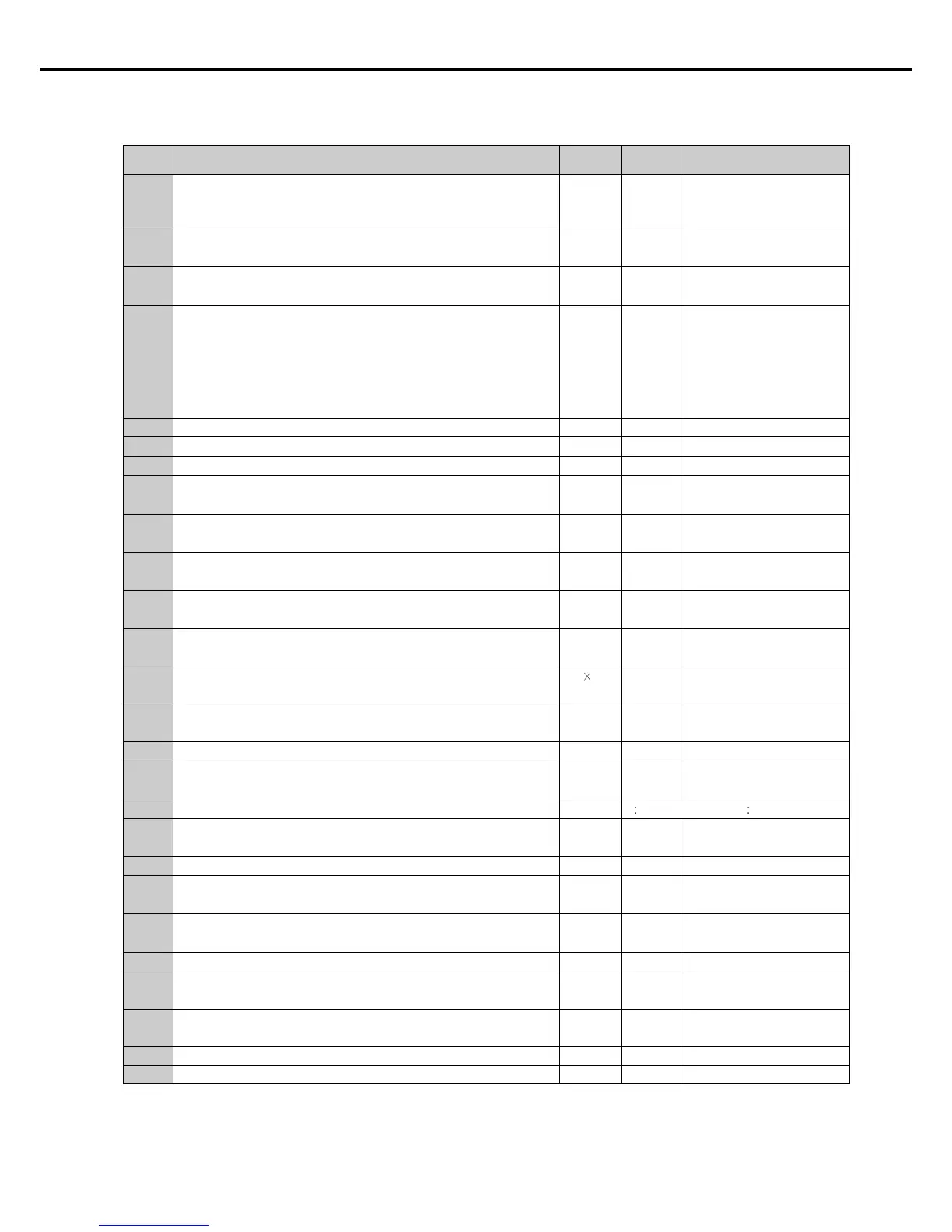

52

No. Function StepRange

Initial value

[ Caution ]

If the specific items of the parameter are changed carelessly, they could break down or damage the machine, so the user must be

well-trained before using it.

0 0/1/2 0=CAM type machine

24

Selection of thread trimming conditions

1= thread trimming after up-stop

(selection according to sewing machine type)

2=thread trimming after low-stop

25 Whether or not to use default sequence when A24 = 1 0 0/1 0=B-55 exclusive sequence is used

(This is a sequence determined on A9,A10 value) 1= default sequence is used

26 Selection of B/T Solenoid operation position 0 0/1 0= lower position

1= upper position

27 Setting the maximum sewing speed of the machine according to ? ? Less than P1xx:3500[spm]

presser foot-lift height of the KM-1060BL sewing machine. Less than P2xx:3000[spm]

Less than P3xx:2500[spm]

More than P3xx: A20[spm]

program P1xx → P2xx → P3xx

in order

28 Needle bar’s automatic stop at the highest position 0 0/1

29 Pedal analog filtering difference 10 1~30 1

30 When using an angle 2-needle, select the semi-automatic corner operation 0 0/1 1=selection of semi-automatic

31 Speed when selecting a semi-automatic corner 200spm 20~2000 10spm

(parameter used only when used after selecting number 30)

32 After selecting the left needle the first sewing stitch 3 stitches 0~255 1 stitch

(parameter used only when used after selecting number 30)

33 After selecting the left needle the second sewing stitch 3 stitches 0~255 1 stitch

(parameter used only when used after selecting number 30)

34 After selecting the right needle the first sewing stitch 3 stitches 0~255 1 stitch

(parameter used only when used after selecting number 30)

35 After selecting the right needle the second sewing stitch 3 stitches 0~255 1 stitch

(parameter used only when used after selecting number 30)

36 Maintaining time for the left/right needle solenoid 450

0.1sec (50~1000) 0.5sec

(After the programmed time the solenoid is automatically released)

37 Set grease check function 0 0/1 0 : Not used

1 : Used

38 Set grease check time 750 (hour) 0~9999 1 (hour)

39 Stopping function during AUTO mode and while pedal is neutral 1 0/1 0=does not stop

1=stops

40 Selection of type of N-stitch Sensor 0 0

active high 1 active low

41 The number of stitches done after the N-stitch Sensor has finished sensing. 3 stitches 0~255 1 stitch

(After sensing, it will sew the programmed number of stitches and stop)

42 N-stitch sewing speed 1000spm 20~2000 10spm

43 Selection of One Touch function 0 0/1 1=Auto Mode

(Used in the sewing mode that uses the auto function)

44 Selection of One Touch function 0 0/1 1=One-Shot Mode

(If there is no thread trimming signal when selected, sewing will continue even if user releases pedal)

45

One-Shot sewing speed

2000spm 40~9960 40spm

46 N-stitch sewing mode selection → a sewing mode that inputs a sensor signal 0 0/1 1=N-stitch Mode

in the edge sensor port and uses it as an edge sensor

47 Selection of pre-stitch function (When selected it will perform only 0 0/1 1=selection

the programmed stitches before the actual sewing work starts)

48 Pre-stitch number of stitches 3 stitches 0~255 1 stitch

49 Pre-stitch speed 2000spm 20~2000 10spm

Loading...

Loading...