54

(2) Group B Parameter : All types of output, Full-on Time/PWM Duty, checking input/output operations, sewing

machine models and thread trimming sequence programming.

These are functions not used by general users and must be regulated by an A/S technician.

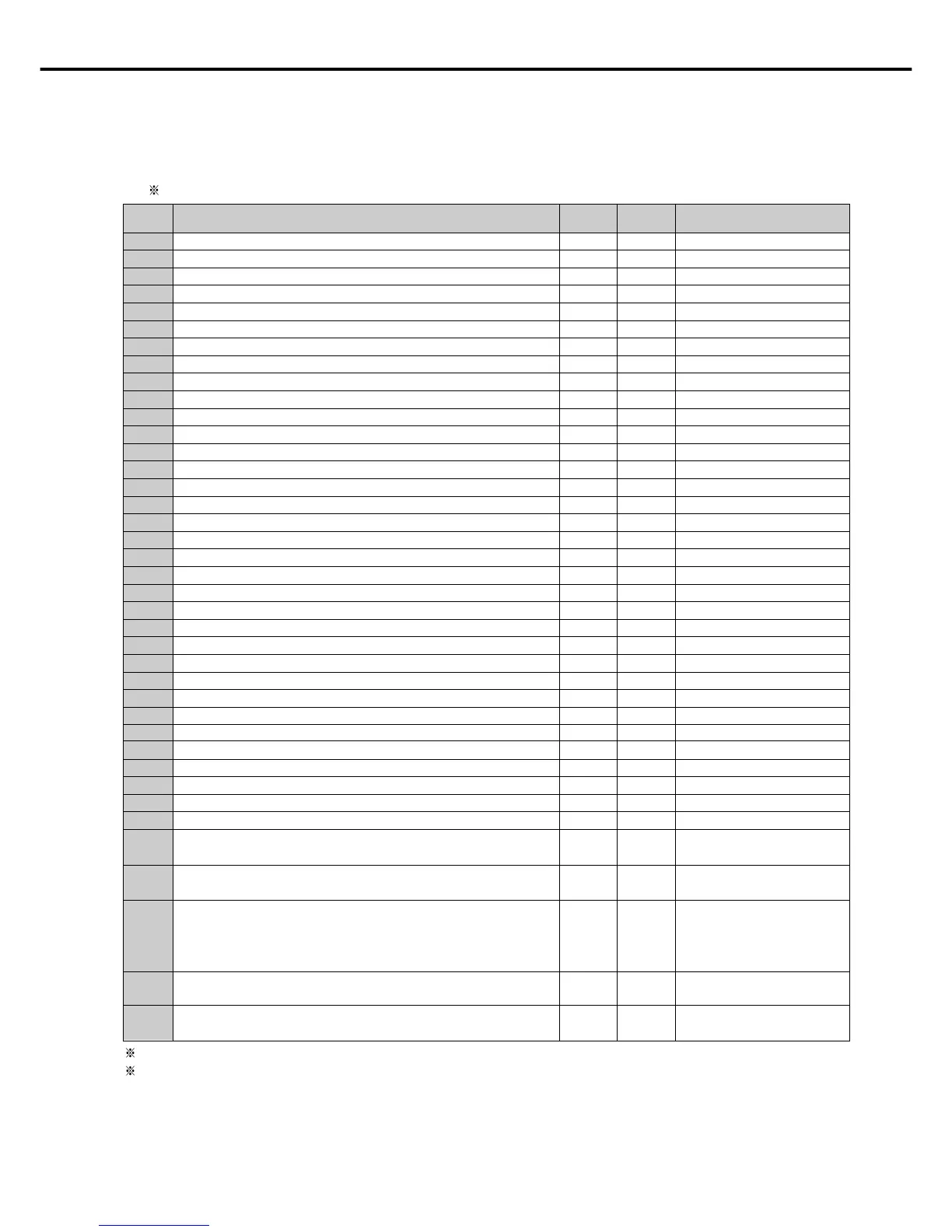

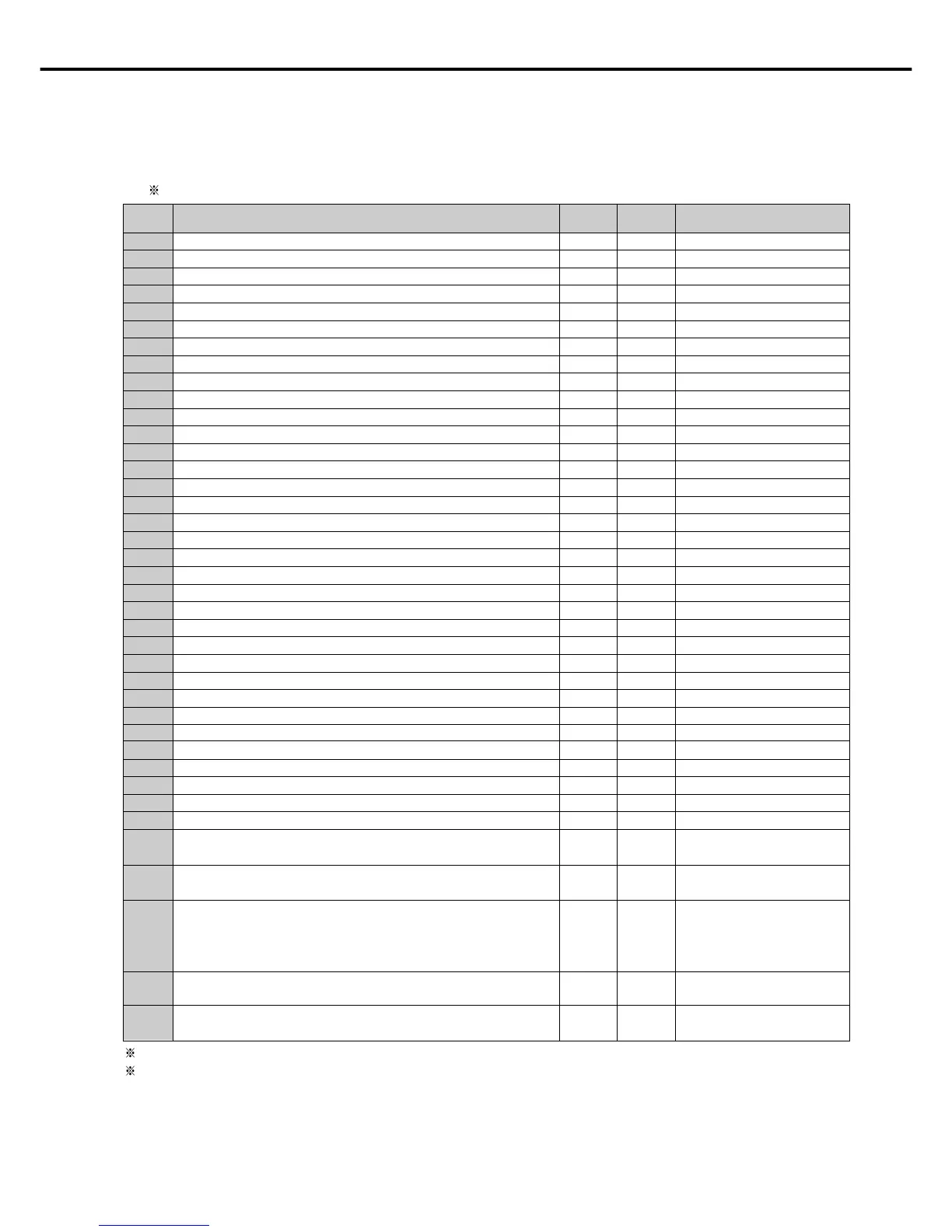

No. Function StepRange

Initial value

[ Caution ]

If the specific items of the parameter are changed carelessly, they could break down or damage the machine, so the user must be

well-trained before using it.

Items No. 30~33 : These are the items that make the number of stitches match when back tack number of stitches do not match.

Solenoid Duty Ratio : The power that holds and maintains the solenoid.

Solenoid initial full on time : The time it takes to pull the solenoid to the maximum in the outset.

1 Back Tack Solenoid Initial Full On Time 1020ms 4~1020 4ms

2 Presser Foot-Lift Solenoid Initial Full On Time 200ms 4~1020 4ms

3 T/T Solenoid Initial Full On Time 100ms 4~1020 4ms

4 Wiper Solenoid Initial Full On Time 100ms 4~1020 4ms

5 Tension Release Solenoid Initial Full On Time 100ms 4~1020 4ms

6 Left Solenoid Initial Full On Time (For Twin Needle) 100ms 4~1020 4ms

7 Right Solenoid Initial Full On Time (For Twin Needle) 100ms 4~1020 4ms

8 Auxiliary Solenoid Initial Full On Time 100ms 4~1020 4ms

9 Left LED Initial Full On Time (For Twin Needle) 100ms 4~1020 4ms

10 Right LED Initial Full On Time (For Twin Needle) 100ms 4~1020 4ms

11 Needle plate up-stop signal Initial Full On Time 100ms 4~1020 4ms

12 Needle plate down-stop signal Initial Full On Time 100ms 4~1020 4ms

13 Signal notifying motor running Full On Time 100ms 4~1020 4ms

14 Signal notifying target speed achieved Full On Time 100ms 4~1020 4ms

15 Back Tack Solenoid Duty Ratio 50% 0~100 10%

16 Presser Foot-Lift Solenoid Duty Ratio 20% 0~100 10

17 Thread Trimming Solenoid Duty Ratio 100 0~100 10

18 Wiper Solenoid Duty Ratio 100 0~100 10

19 Tension Release Solenoid Duty Ratio 100 0~100 10

20 Left Solenoid Duty Ratio (For Twin Needle) 50 0~100 10

21 Right Solenoid Duty Ratio (For Twin Needle) 50 0~100 10

22 Aux Solenoid Duty Ratio 100 0~100 10

23 Left LED Duty Ratio (For Twin Needle) 100 0~100 10

24 Right LED Duty Ratio (For Twin Needle) 100 0~100 10

25 Signal for up stopping needle Duty Ratio 100 0~100 10

26 Signal for low stopping needle Duty Ratio 100 0~100 10

27 Signal notifying motor running Duty Ratio 100 0~100 10

28 Signal notifying target speed reached Duty Ratio 100 0~100 10

29 NOT USED

30 Start Back Tack A number of stitches correction value 00.30 6~6 0.05 Stitch

31 Start Back Tack B number of stitches correction value 00.30 6~6 0.05 Stitch

32 End Back Tack C stitch correction value 00.40 6~6 0.05 Stitch

33 End Back Tack D stitch correction value 00.40 6~6 0.05 Stitch

34

Selection for maintaining reverse solenoid movement when thread trimming (C Only B/T)

0 0/1 1=reverse direction maintained

35

Programming count condition 0 0/1 0=counter used

(program whether or not automatic counter will be operated)

1=automatic counter after thread trimming

36

When automatically counting, select Up/Down count after thread

1 0/1

1=Up COUNT

trimming (thread trimming function must be enabled) 0=DOWN COUNT

0=buzzer rings, sewing is allowed

37 When count in completeded, the next operation is programmed 0 0/1/2

1=buzzer rings, sewing is not allowed

(If you press the Prog Key, set up is cancelled)

2=No buzzer ring, sewing is allowed

38 When count is completed, select the counter auto clear/preset 0 0/1

1=AUTO

CLEAR/PRESET

39 Bobbin counter set-up

0 0/1

0=Bobbin counter Disable

1=Bobbin counter Enable

Loading...

Loading...