34

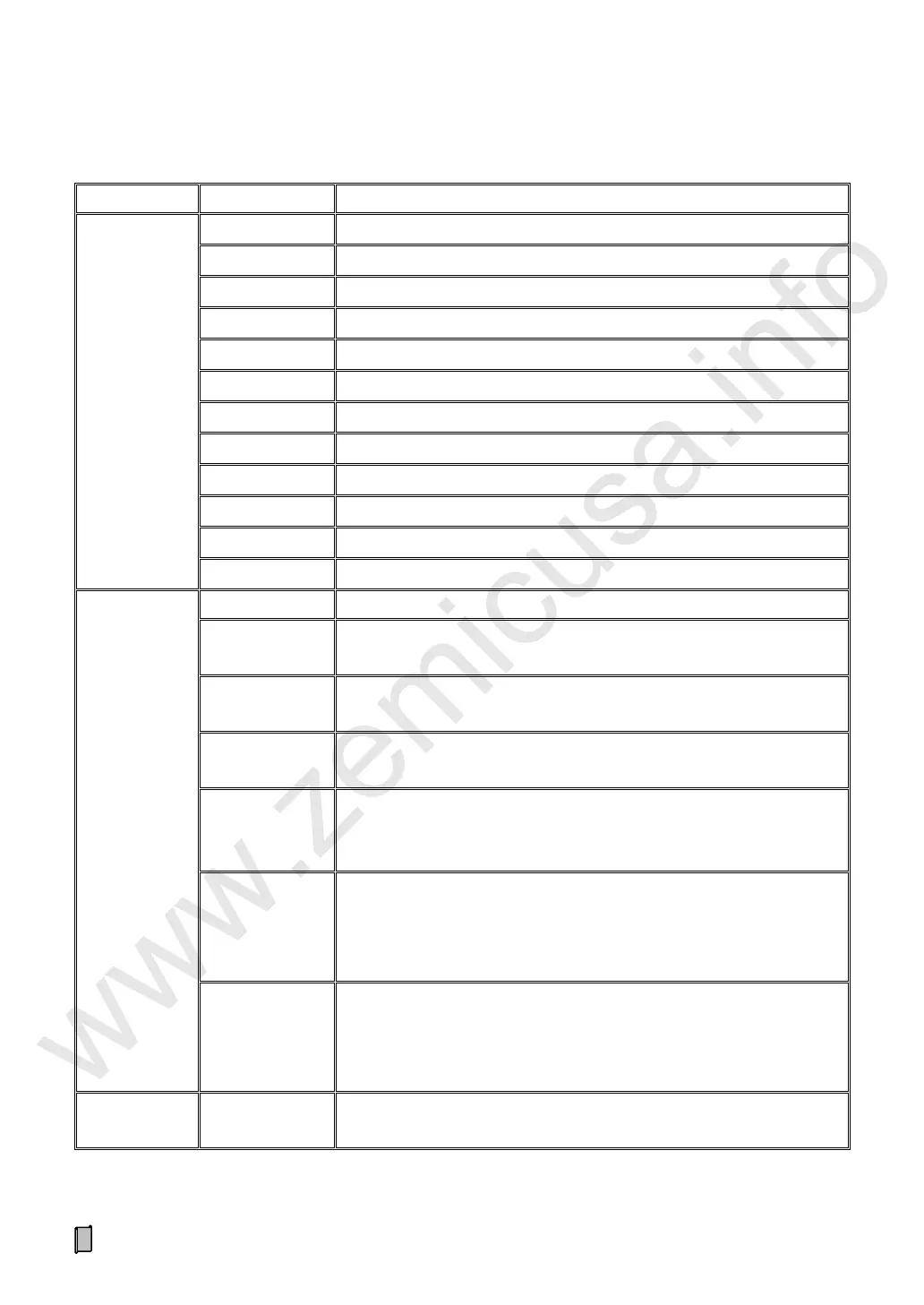

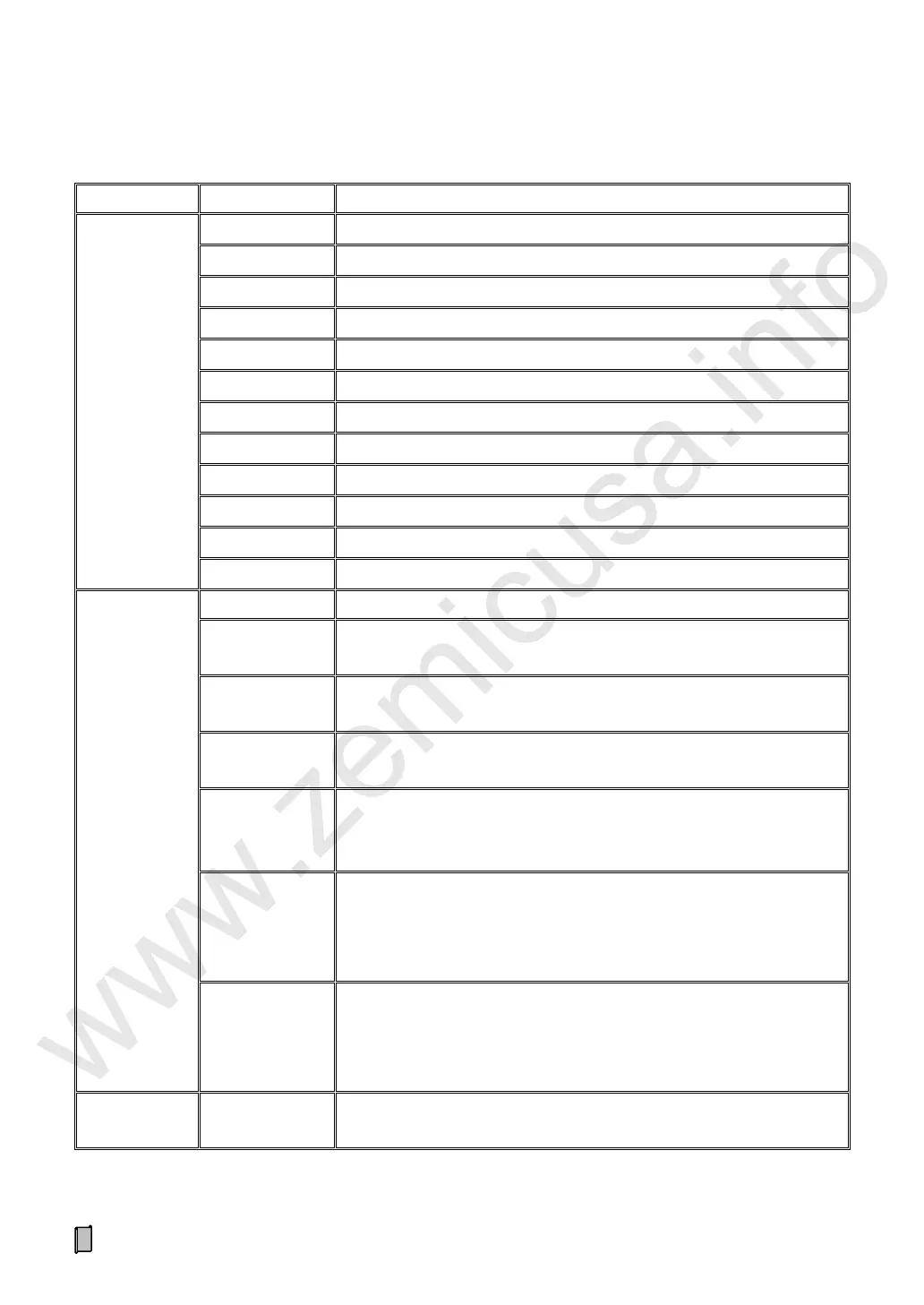

6.2 Main MENU

Basic scale parameters setting.

Extra scale parameters setting.

Basic feeding control parameters setting.

Extra feeding and batching control parameters setting.

Speed parameters setting.

Weight record parameters setting.

Communication parameters setting.

Input/output parameters setting.

Display and operation interface parameters setting.

Date/Time parameters setting.

Zero Calibration without loading for correcting Zero Value.

Dynamic Span Calibration with loading materials or Poise Weights for

correcting Span Coefficient.

Static Span Calibration with a measured chain weight as a continuous and

steady load on the running belt weigher for correcting Span Coefficient.

Static Span Calibration with a measured Hanging Weight as a steady load

on the running belt weigher for correcting Span Coefficient.

Segmenting Span Correction. After doing Dynamic or Static Span

Calibration, further corrections for 3 [AD Value: 0~60000] linear segments

are optional for correcting Correction Coefficient 1~3.

Speed Coefficient Calibration.

Keep the belt weigher running at a constant speed. After the running time of

a revolution being measured with using a stopwatch, do this operation for

correcting Speed Coefficient.

Belt Length Calibration.

Keep the belt weigher running at a constant speed. After the running time of

a revolution being measured with using a stopwatch, do this operation for

correcting Belt Length.

Query and print Weight Records.

Loading...

Loading...