GB.GOLDSK509.091101

We reserve the right to alter specifications without notice.

www.swegon.com 11

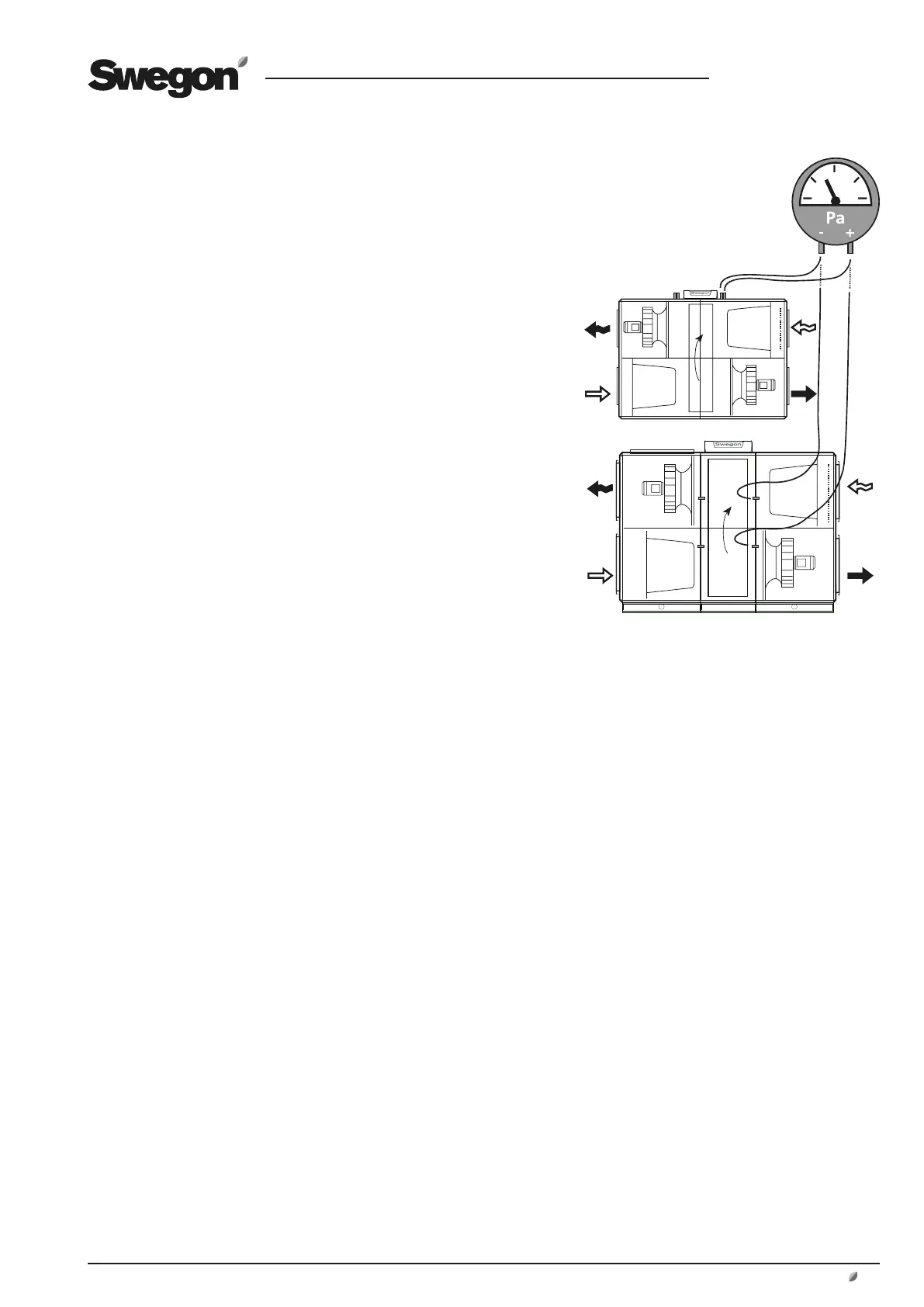

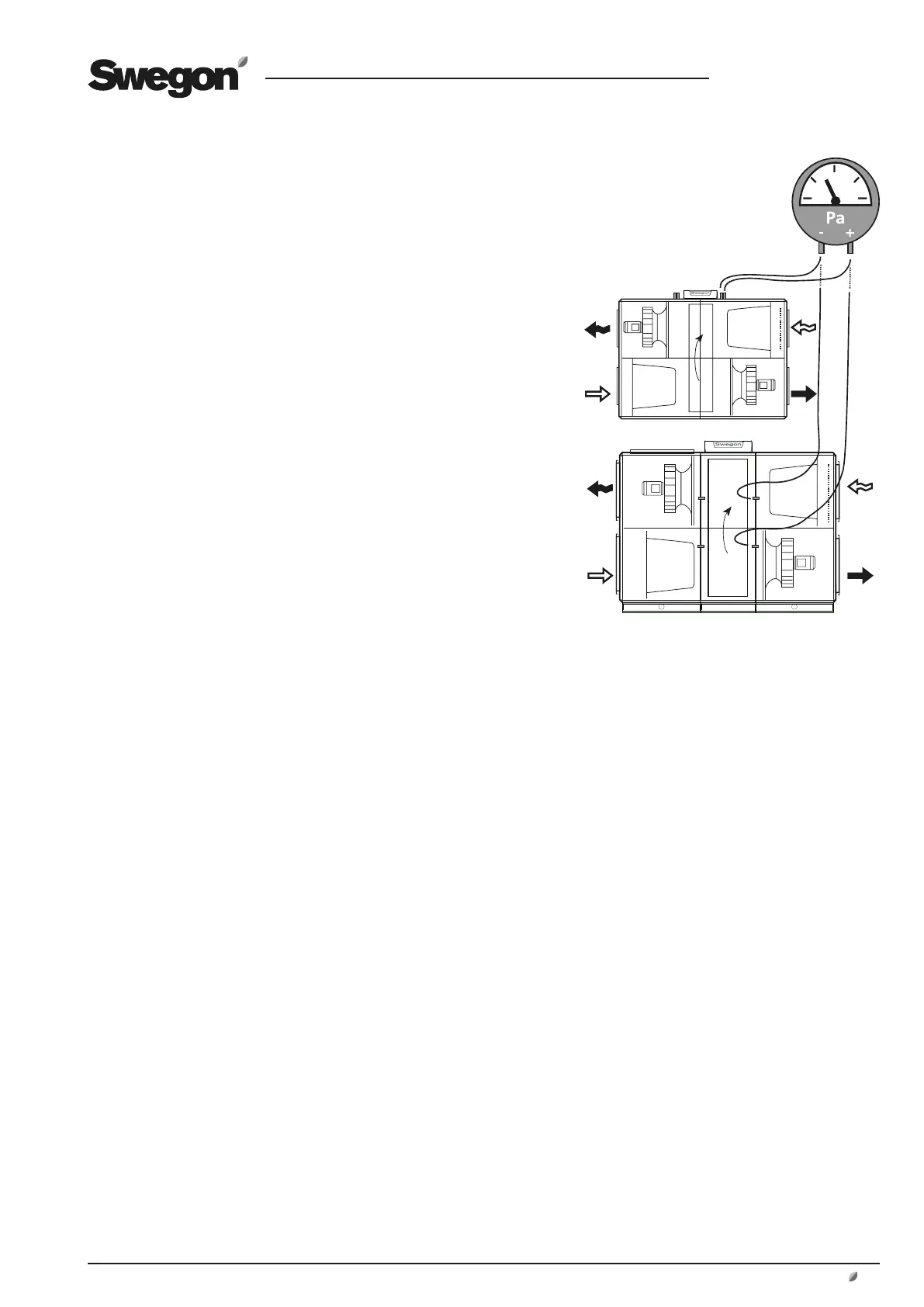

3.3.2 To Ensure the Correct Leakage Direction

The adjustment plates fitted in the extract air inlet are

used for adjusting the pressure balance in the unit. The

adjustment plates are supplied separately and should be

fitted in the unit by the fitter when he connects the extract

air ducting to the air handling unit. See the illustrations on

the previous page.

Connect a pressure gauge to the pressure measurement

tappings of the unit.

The unit has four pressure measurement tappings; the two

closest to the extract air duct should be used. The blue

pressure measurement tapping measures the negative

pressure in the extract air section and the white pressure

measurement tapping measures the negative pressure in

the supply air section.

On the size 04-08 units, the pressure measurement tap-

pings are by the junction hood and on the size 12-80 units

they are inside in the centre section of the unit.

See illustration to the right.

Note that both pressure measurement tappings measure

negative pressure.

MEASURED VALUES

The negative pressure in the extract air section should be

greater or the same as the one in the supply air section.

If the negative pressure in the extract air section is the

same or up to 20 Pa more than the negative pressure in

the supply air section, then you’ve finished this adjust-

ment.

DEVIATIONS

If the negative pressure in the extract air section is less

than that in the supply air section, the adjustment plates

must be readjusted as follows:

1. Stop the unit, open the inspection door to the extract

air filter.

GOLD RX Top: blank off a number of holes in the flow

adjustment plate with the plastic plugs supplied with the

unit.

Other models: slightly push the flow adjustment plates

forward (close them) in the extract air intake opening.

For full face connection (duct accessory in insulated

casing): If the commissioning plate(s) is/are completely

closed and the sub-atmospheric pressure in the extract air

section is still less than in the supply air section, blank off

a number of holes in the commissioning plate with the

plastic plugs supplied.

3. Close the inspection door and restart the unit.

4. Measure the pressures.

Repeat until the negative pressure in the extract air section

is the same or up to 20 Pa higher than the negative pres-

sure in the supply air section (0–20 Pa).

Pressure measurement nipples -

leakage direction

(Unit in right-hand version)

- (blue)

+ (white)

GOLD 04-08

GOLD 12-80

– (blue)

+ (white)

EXTRACT AIR

EXTRACT

AIR

5. If the negative pressure in the extract air section is

higher than 20 Pa compared to the supply air section,

although the adjustment plates are completely open, the

leakage and purging air flow will be more than anticipat-

ed. This means that the actual extract air flow will deviate

from the preset extract airflow. The deviation increases

with increased pressure differential.

Loading...

Loading...