MAINTENANCE

After First

50

Hours (New Machines Only)

Inspecting and Adjusting the Fan

Belt

AwARNING

Stop the engine and allow the machine

to cool before performing inspection and

maintenance.

• The engine, muffler, radiator, hydraulic

lines, sliding parts and many other

parts of the machine are hot directly

after the engine

is

stopped. Touching

these parts will cause burns.

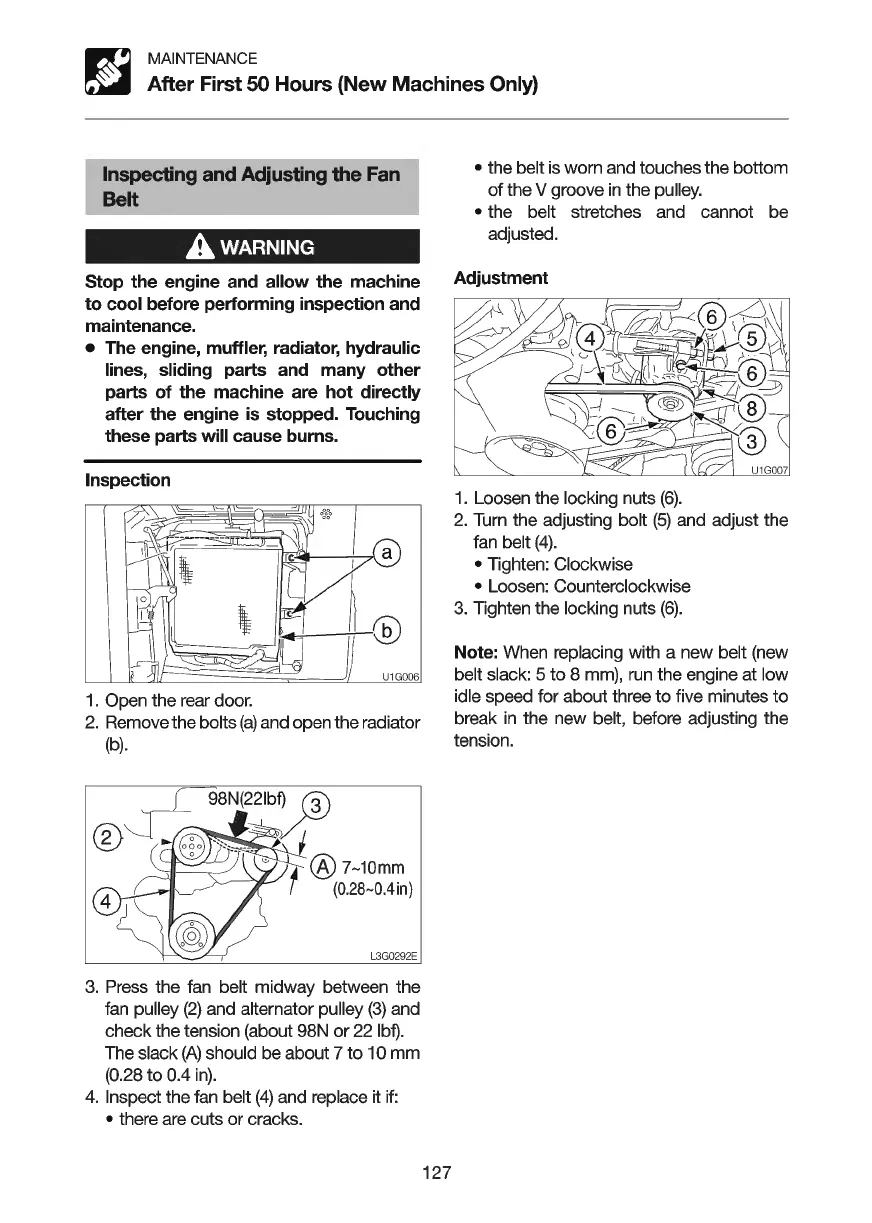

Inspection

1 . Open the rear door.

2. Remove the bolts

(a)

and open the radiator

(b)

.

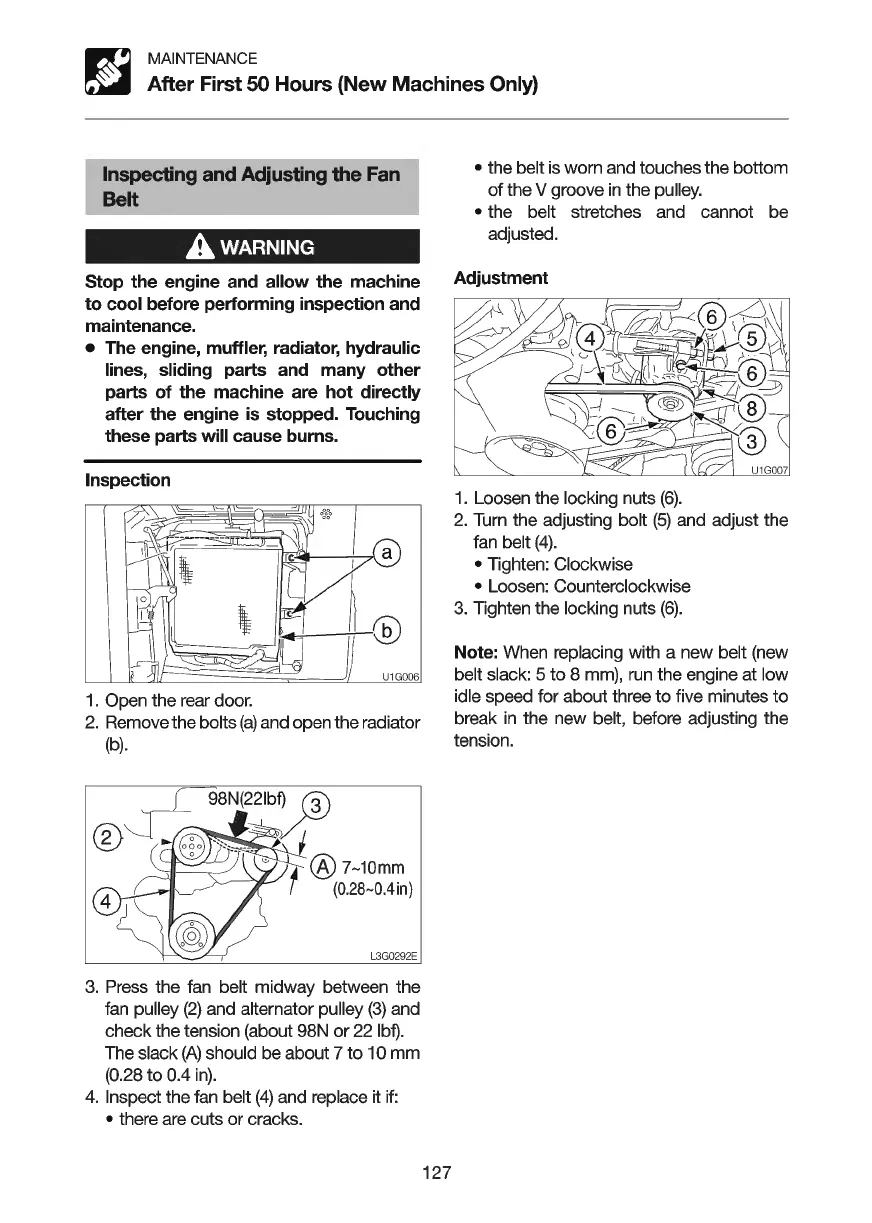

3. Press the fan belt midway between the

fan pulley

(2)

and alternator pulley

(3)

and

check the tension (about 98N

or

22

lbf).

The slack

(A)

should be about 7

to

1 0

mm

(0.28

to

0.4

in)

.

4.

Inspect the fan belt

(4)

and replace it if:

• there are cuts or cracks.

127

• the belt is worn and touches the bottom

of

the V groove

in

the pulley.

• the belt stretches and cannot be

adjusted.

Adjustment

1.

Loosen the locking nuts

(6).

2.

Turn the adjusting bolt

(5)

and adjust the

fan belt

(4)

.

• Tighten: Clockwise

• Loosen: Counterclockwise

3.

Tighten the locking nuts

(6).

Note: When replacing with a new belt (new

belt slack:

5 to 8 mm),

run

the engine at low

idle speed for about three

to

five minutes

to

break

in

the new belt, before adjusting the

tension.

Loading...

Loading...