31

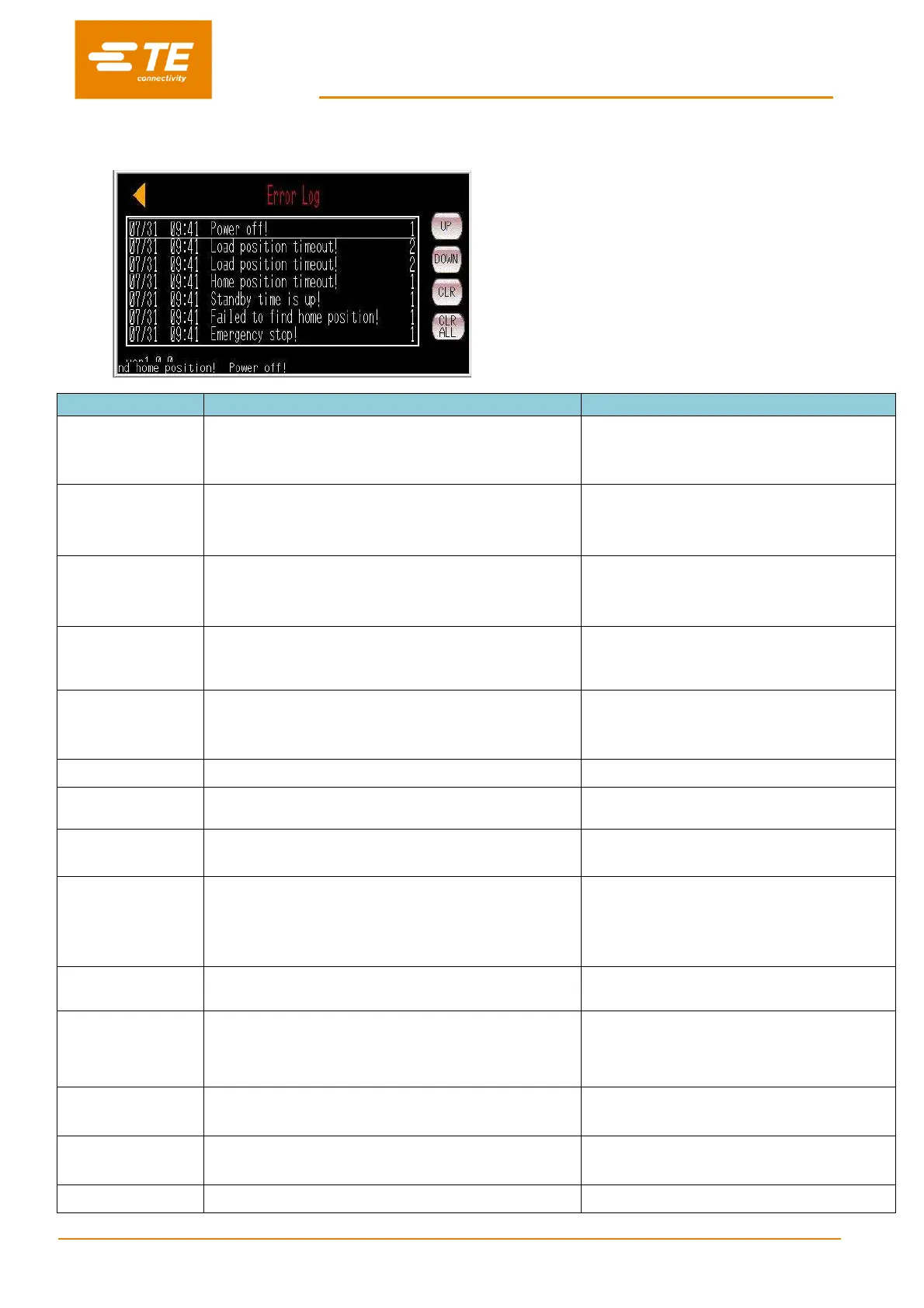

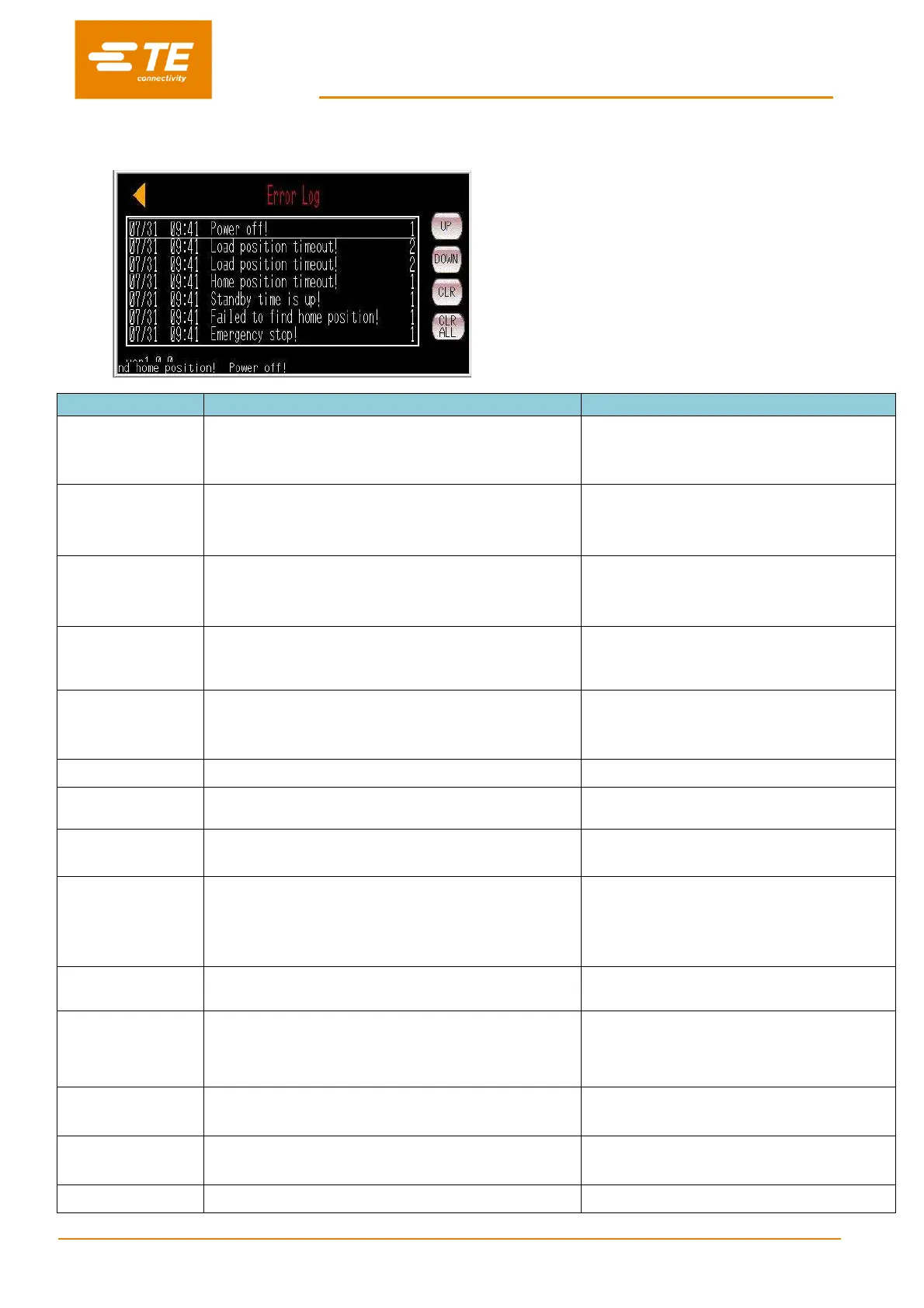

3.10 Error Log

This page will show error message on HMI. Other

processor issue please find from section 4.3

Troubleshooting

The processor isn't powered off in right process

1. Emergency stop button be pushed

2. The power supply is cut

1. Check the emergency stop button was pressed

or not

2. Check the power supply of processor

1. Load position sensor error

2. The heating chamber be jammed

3.The motor error

1. Check load position sensor

2. Check the heating chamber be jammed or not

3. Check the motor

1. Home position sensor error

2. The heating chamber be jammed

3.The motor error

1. Check home position sensor

2. Check the heating chamber be jammed or not

3. Check the motor

The time that operator doesn't operate the processor is

longer than the stan-by time, the processor is in standby

mode automatically

Press the IO button for 5s to power on the

processor

Failed to find home

position!

When power on the processor the heating chamber isn't

on home position, and push two hands buttons, the

heating chamber can't back to home position

1. Check home position sensor

2. Check the heating chamber be jammed or not

3. Check the motor

Emergency stop button be pushed

Release the emergency stop button

Setting temperature

too high!

Setting temperature value is higher than 675℃

Reset the temperature value lower than 675℃

Actual temperature is higher than 675℃

1. Check the temp sensor

2. Check the temp controller

Temp controller

comm error!

1. The communication cable between PLC and temp

controller is damaged

2. The PLC communication port is damaged

3. The temp controller error

1. Check the communication cable between PLC

and temp controller

2. Check the PLC communication port

3. Check the temp controller

Temperature error!

Check heating circuit!

Actual Temperature is higher than set temperature 10℃ or

lower than set temperature 10℃

Check the connect between temperature

controller and PLC

After 90s, actual temperature is lower than 180℃ when

set temperature is higher than 200℃

1. Check solid-state relay

2. Check Master control relay

3. Replace the master control relay.

1. Probe up/down sensor error

2. Inner connection of CD cable fail

1. Check the sensor

2. Reconnect the cable from top front cover

T/P to side/center

alarm!

1. T/P side/center sensor error.

2. Outer connection of CD cable fail

1. Check the sensor

2. Reconnect the outer CD cable

1. Push tube sensor error.

Loading...

Loading...