Air System Maintenance

Inadequate delivery pressure or defective components operations can generally be traced

to leakage, blocked lines, or the buildup of moisture and sediment in the system. A regular

program of preventive maintenance is an essential part of air system operation. The

materials presented here are listed in accordance with the MAINTENACE CHECK LIST in

this section. Consideration of severe working conditions may dictate a revision in schedule

periodic checks.

DAILY:

AIR TANKS

Open the air tank drain cocks at least once daily to blow out moisture and accumulated

sediment. The drain cocks are located on the frame rail by the battery box.

WEEKLY:

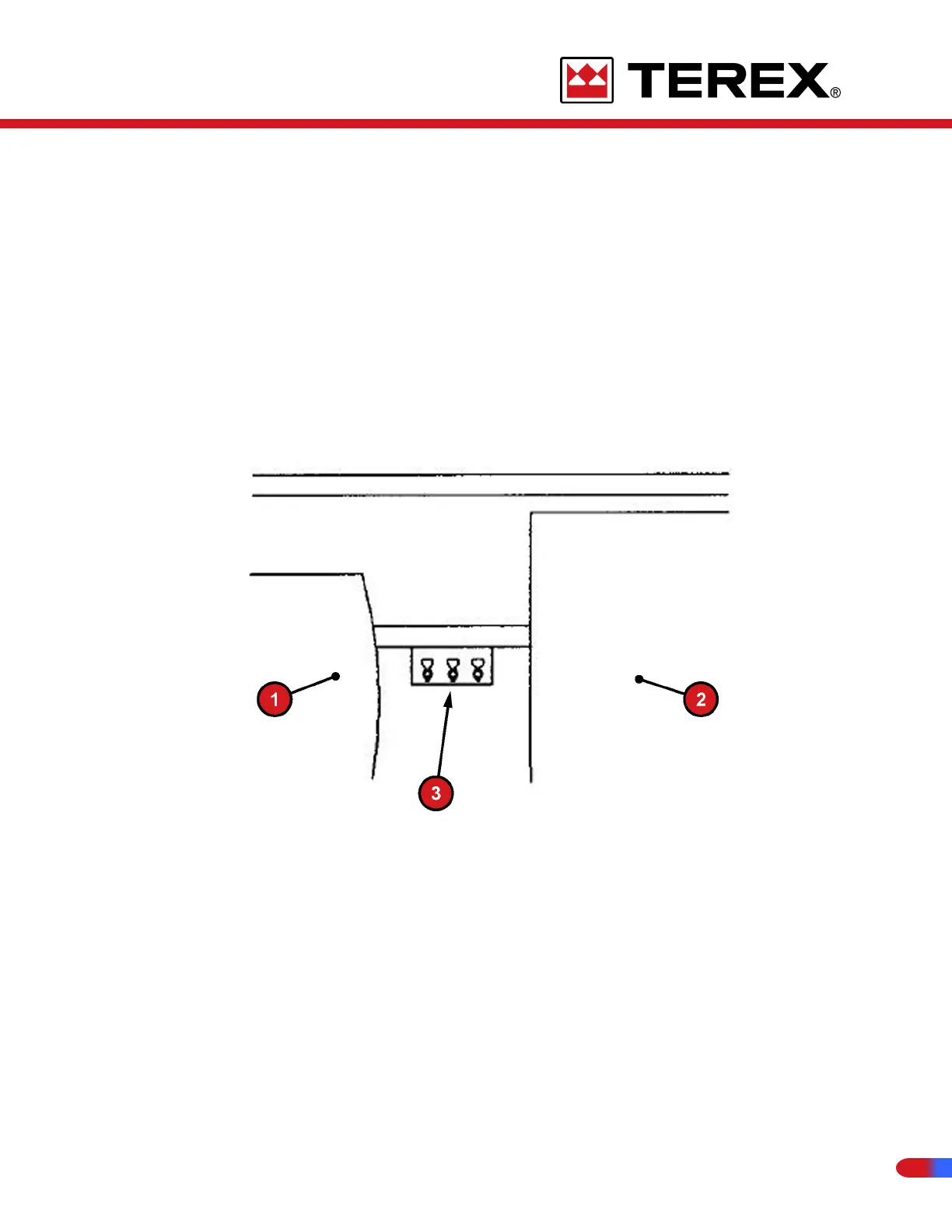

AIR SYSTEM SAFTY VALVE

Manually actuate the air system safety relief valve (1) by pushing in on the stem. This will

ensure that the valve is not sticking. If the valve cannot be actuated in this manner, it

should be repaired or replaced.

157

REVISED:

Loading...

Loading...