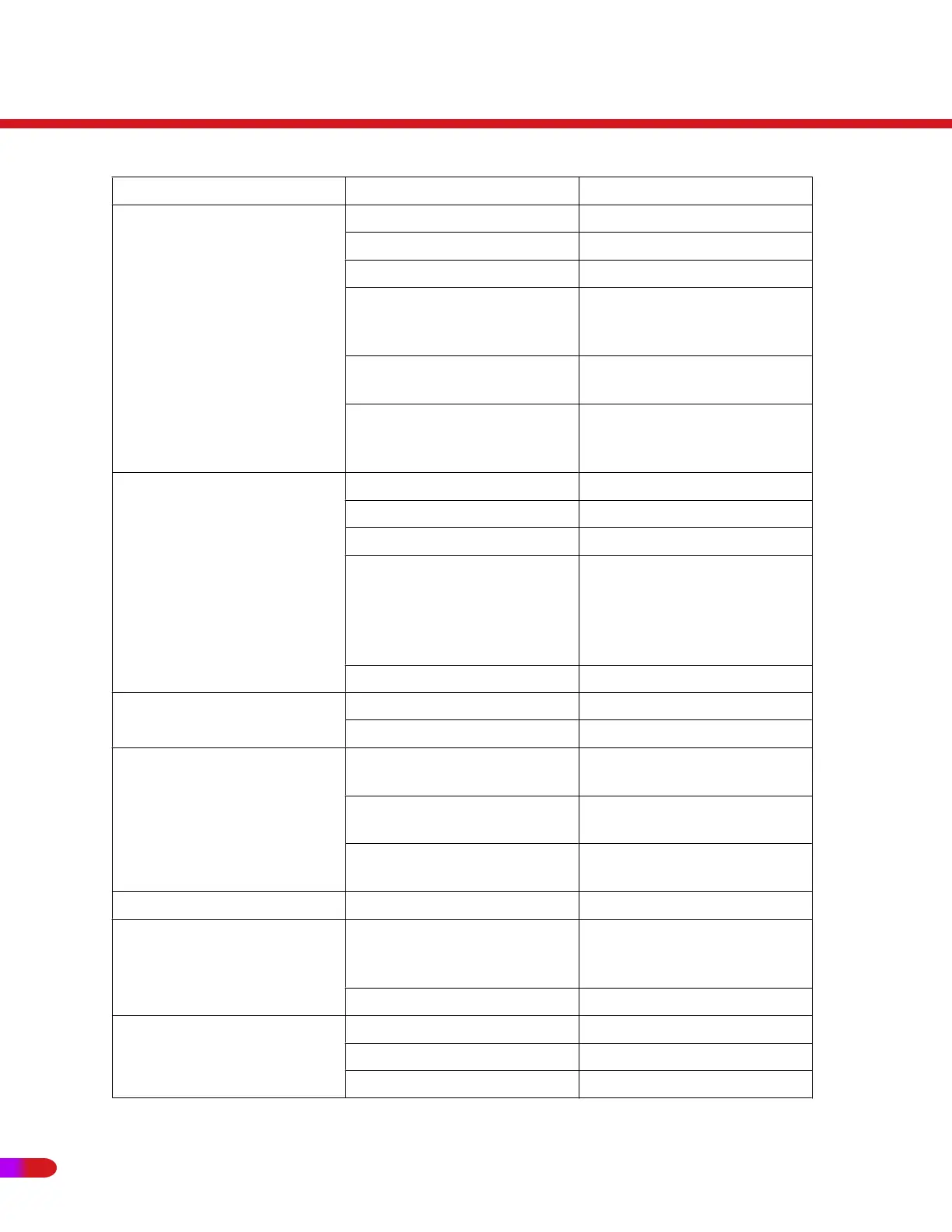

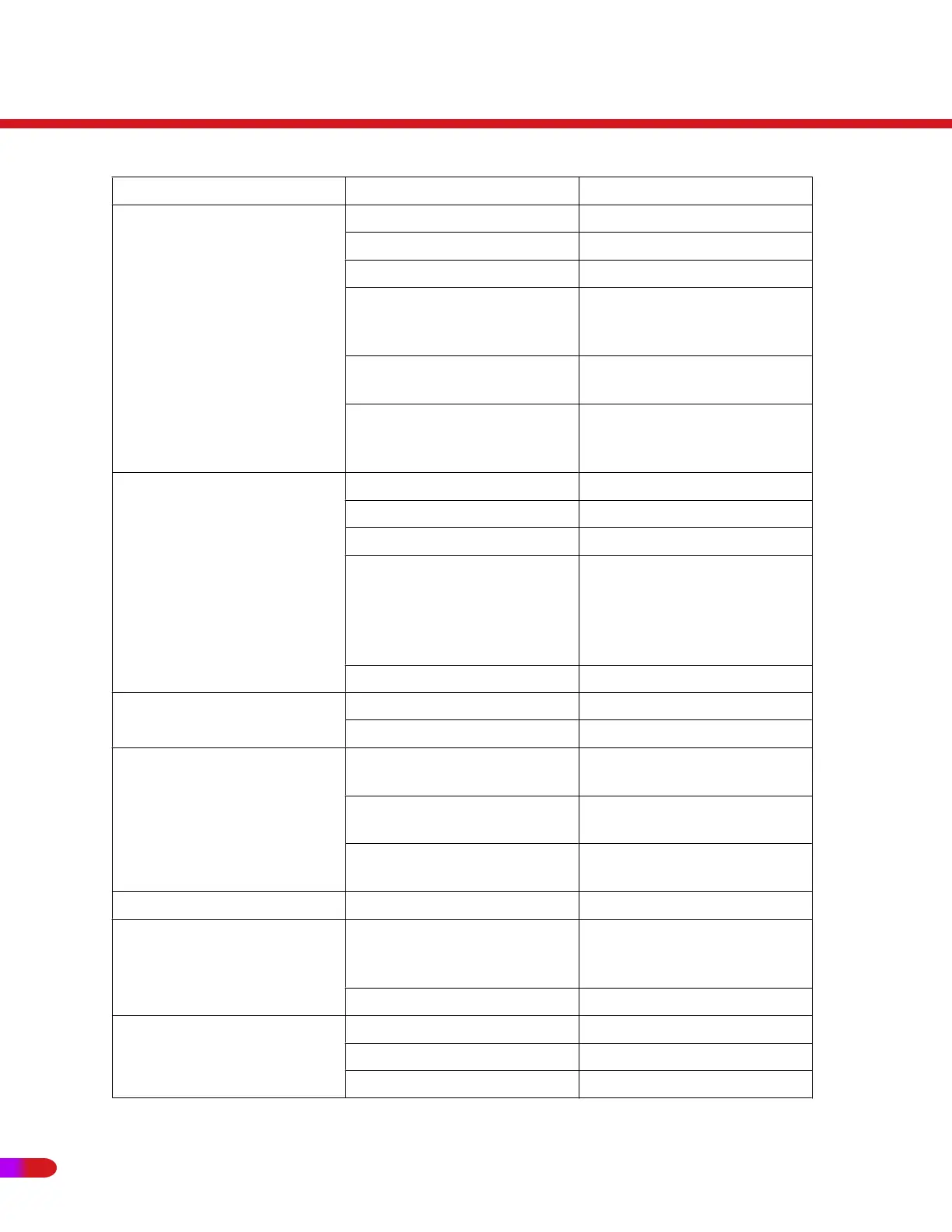

Fluid Motor

CONDITION CAUSE REMEDY

MOTOR WILL NOT TURN Pumps not engaged Engage pumps

No oil Fill reservoir to proper oil level

Pump broken Replace pump

Relief valve stuck open or set

too low

Clean and free relief valve

spool and adjust to proper

setting

Work load jammed or stuck Remove obstruction from

work load

Large contaminating foreign

bodies in fluid

Flush hydraulic system

completely. Use new oil and

install new filters

SLOW OPERATION Wrong oil viscosity Use proper viscosity oil.

Rotary manifold leaking Reseal rotary manifold

Worn pump Repair or replace pump

Extremely high fluid

temperatures causing pump

and motor to slip

(temperature increases as

pump and motor wear)

Add heat exchangers

Relief setting too low Set relief valve for proper psi

MOTOR TURNS IN WRONG

DIRECTION

Hose connections wrong Reverse connections

Wrong timing Re-time motor

ERRATIC MOTOR

OPERATION

Relief valve pressure set too

low

Adjust relief valve setting

Low oil level in reservoir

permitting air to enter system

Fill reservoir to proper level

Air being “sucked in” on inlet

side of pump

Tighten fitting(s) on pump

inlet side

LEAK AT SHAFT Worn or cut shaft seal Replace shaft seal

LEAK BETWEEN HOUSING

AND WEAR PLATE OR

BETWEEN WEAR PLATE

AND GEROLER ASSEMBLY

Motor housing bolts loose Clean mating surfaces and

tighten nuts to appropriate

value.

Pinched “O” ring seal Replace

LEAK AT OIL PORTS Damaged seal or “O” ring Replace “O” ring or seal

Poor fittings Replace fittings carefully

Damaged threads Replace housing

RT500

Troubleshooting

228 REVISED:

Loading...

Loading...