©2004 TESA Switzerland All Rights Reserved.

Page 3-10

User's Manual

MH3D

Moving the Axes

A position at the front of the machine is a comfortable one for most operations.

This permits easy access to the measuring envelope while watching the video

display on the MH3D enclosure.

The movement of each axis through the measuring envelope is accomplished by

pushing or pulling on the Z-rail. The Z-rail has finger pads at its lower end for

gripping. Stops are provided at both ends of the three axes to prevent overtravel.

Care should be taken to slow down when approaching the stops to prevent

banging.

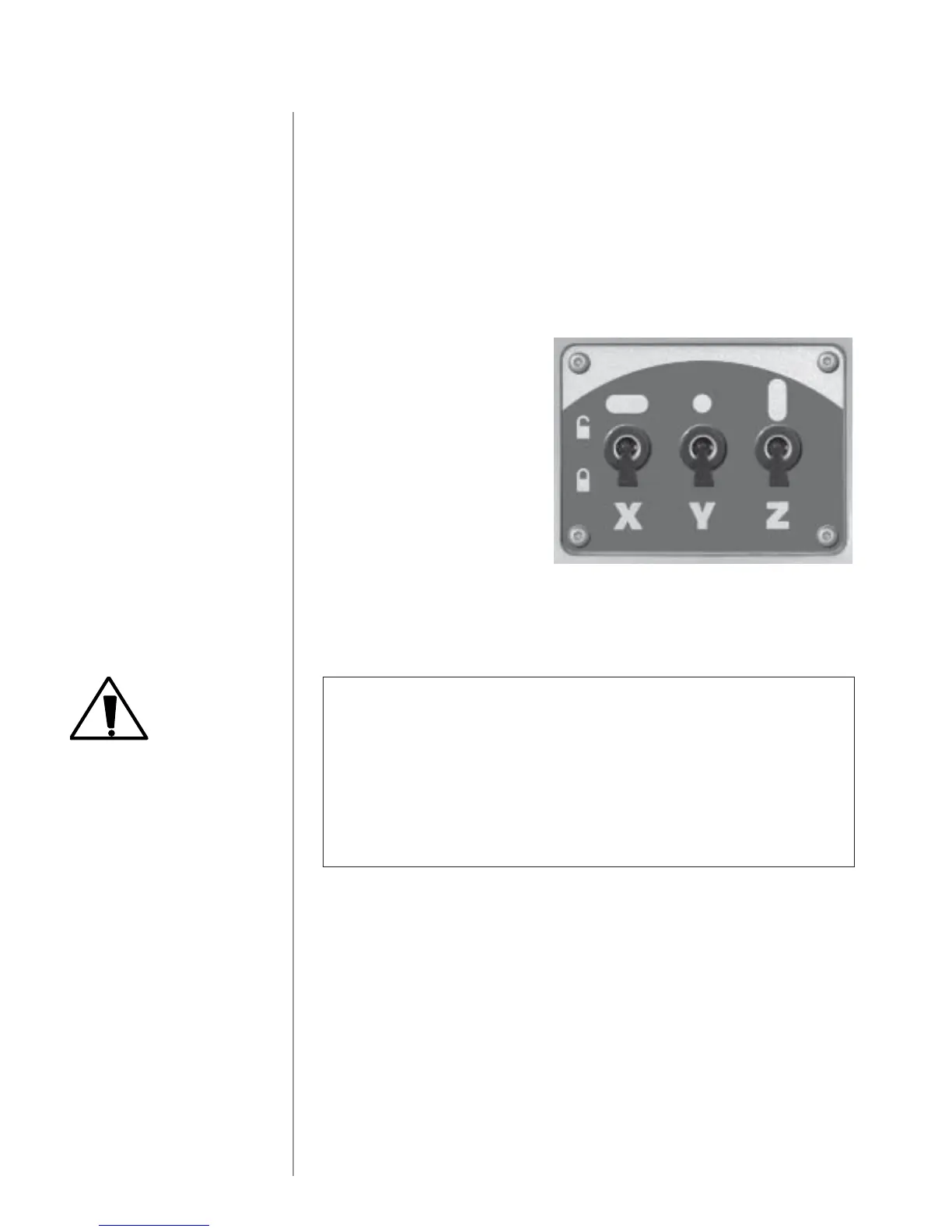

On the MH3D each axis is

provided with a locking system.

This system consists of three

switches, mounted on the left leg,

that control the flow of air to the

locking air bearings. Turning a

switch to "off" (down) deflates the

preloaded air bearings for that axis

and locks the axis.

The Z-rail counterbalance system

equalizes the weight of the rail so

that it moves easily up and down.

The regulator that controls the counterbalance is located at the right side of the

ZX carriage. It must be adjusted to compensate for varying probe weights. If the

counterbalance pressure is adjusted too low, it will trigger the safety valve

causing the Z-axis bearings to deflate and lock.

CAUTION

On the MH3D do not attempt to move any axis with the air supply

to that axis turned off.

Do not attempt to adjust the Z-rail counterbalance with the axis

locked. Hold the Z-rail firmly when unlocking the Z-axis. The rail,

if not properly adjusted, may move suddenly when the axis lock

is released.

On the MH3D, the axes can be precisely adjusted by means of a rod and bearing

arrangement that acts like a fine pitch screw. The rod is turned by means of

large, knurled knobs mounted on both ends of the X-axis and Y-axis and at the

lower end of the Z-axis. There are switches on each of the individual fine adjust

mechanisms that are used to engage or release the mechanism.

Loading...

Loading...