A40i, A60i

OPERATION Manual 0-5466

4-8

4.03 Marking

Gas Type

1. The first thing you will want to do is determine which type of gas to use. When marking, you will use either

air or argon and they both have their advantages and disadvantages. This chart helps to make the best choice.

MARKING

Air Argon

Advantage

•Lower Cost

•Excellent process overall

•No or little slag on mild steel

•Low heat imput which reduces the

risk of deformation

•High contrast

Disadvantage

•High heat input. Can be a problem

for thin material

•Edges may be jagged when used

on aluminum

•Wider markings and more dross

than argon

•Higher cost than air.

•When heavy scoring is needed there

is more slag on mild steel

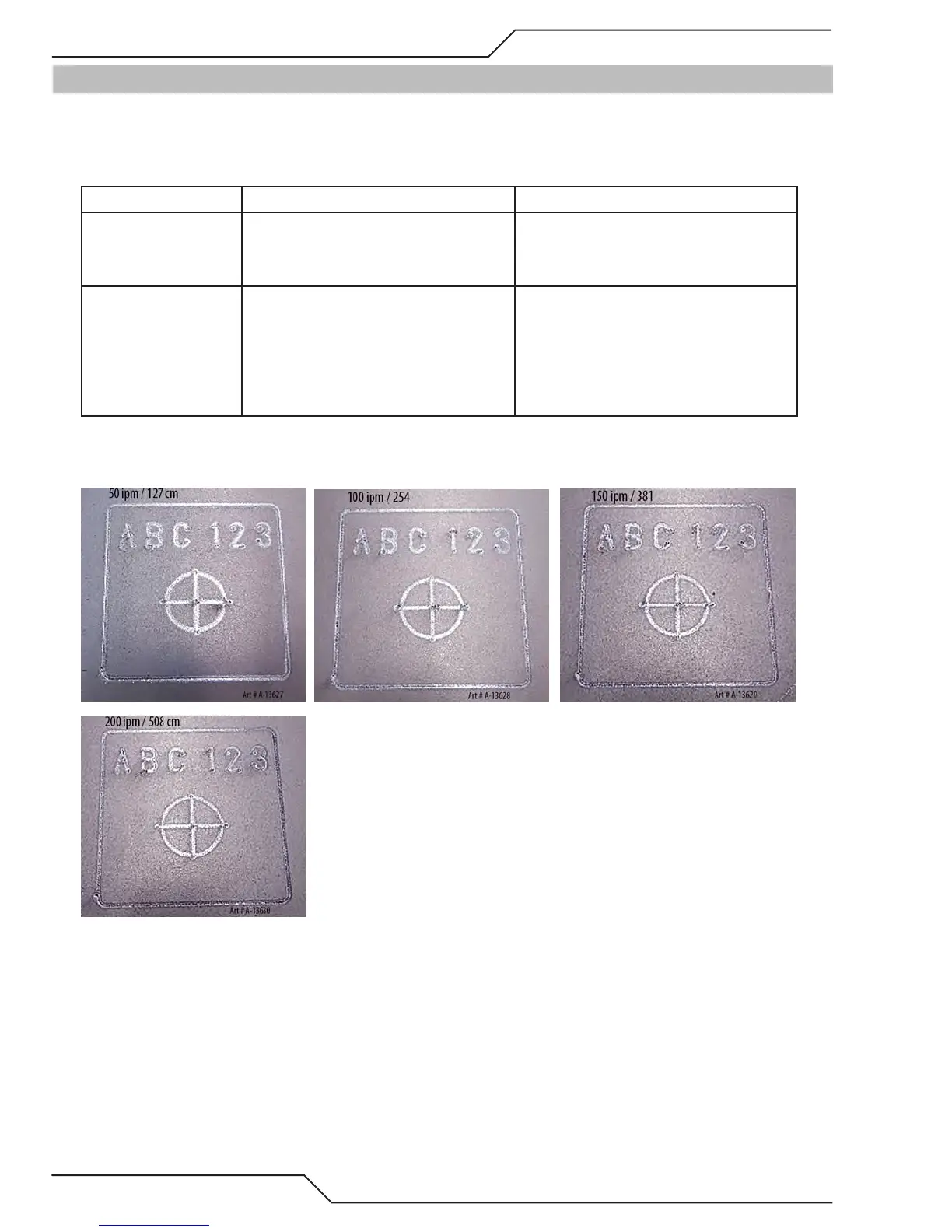

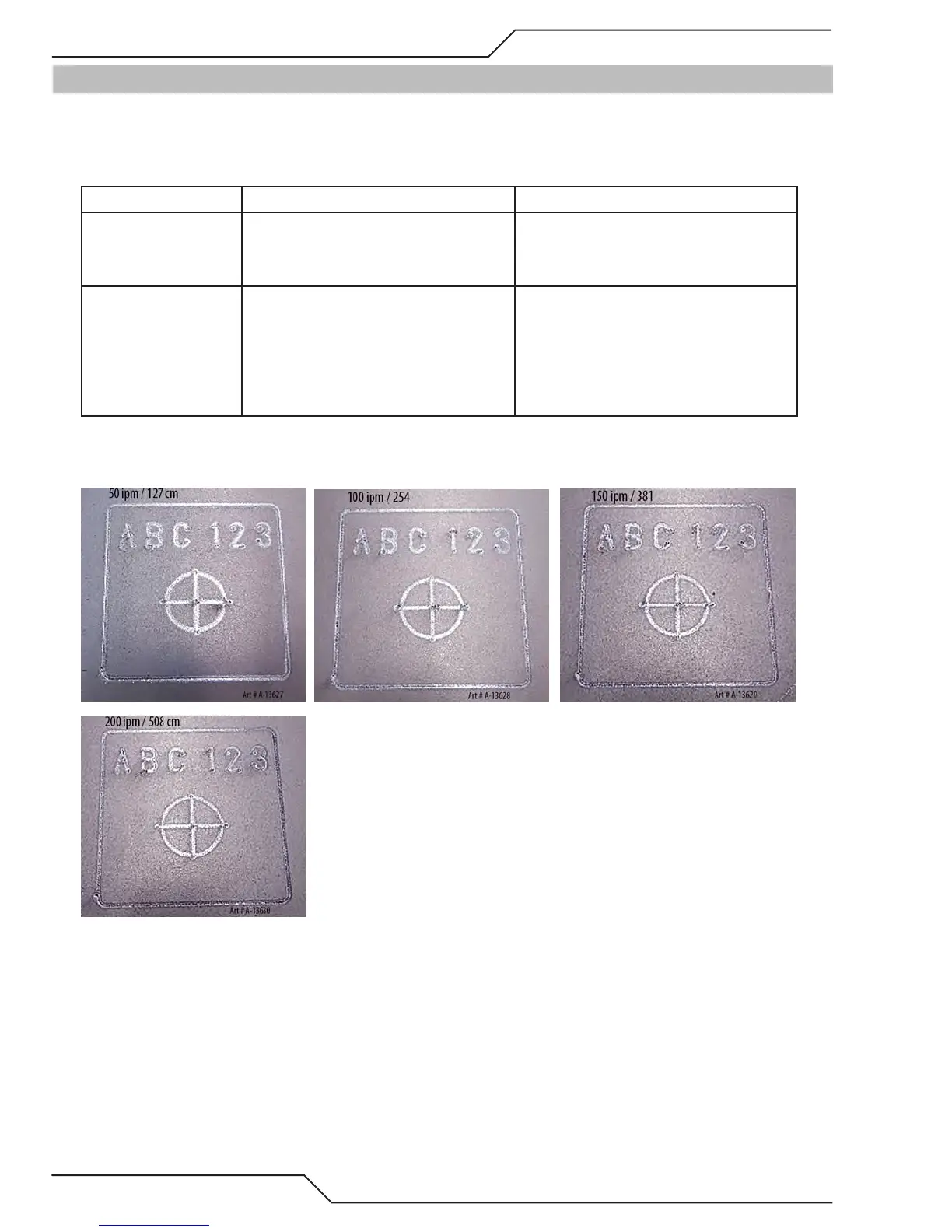

Marking Samples at 10 Amps and 0.100" / 2.5mm Stando.

Marking with Air:

Loading...

Loading...