3. Hold the torch away from your body.

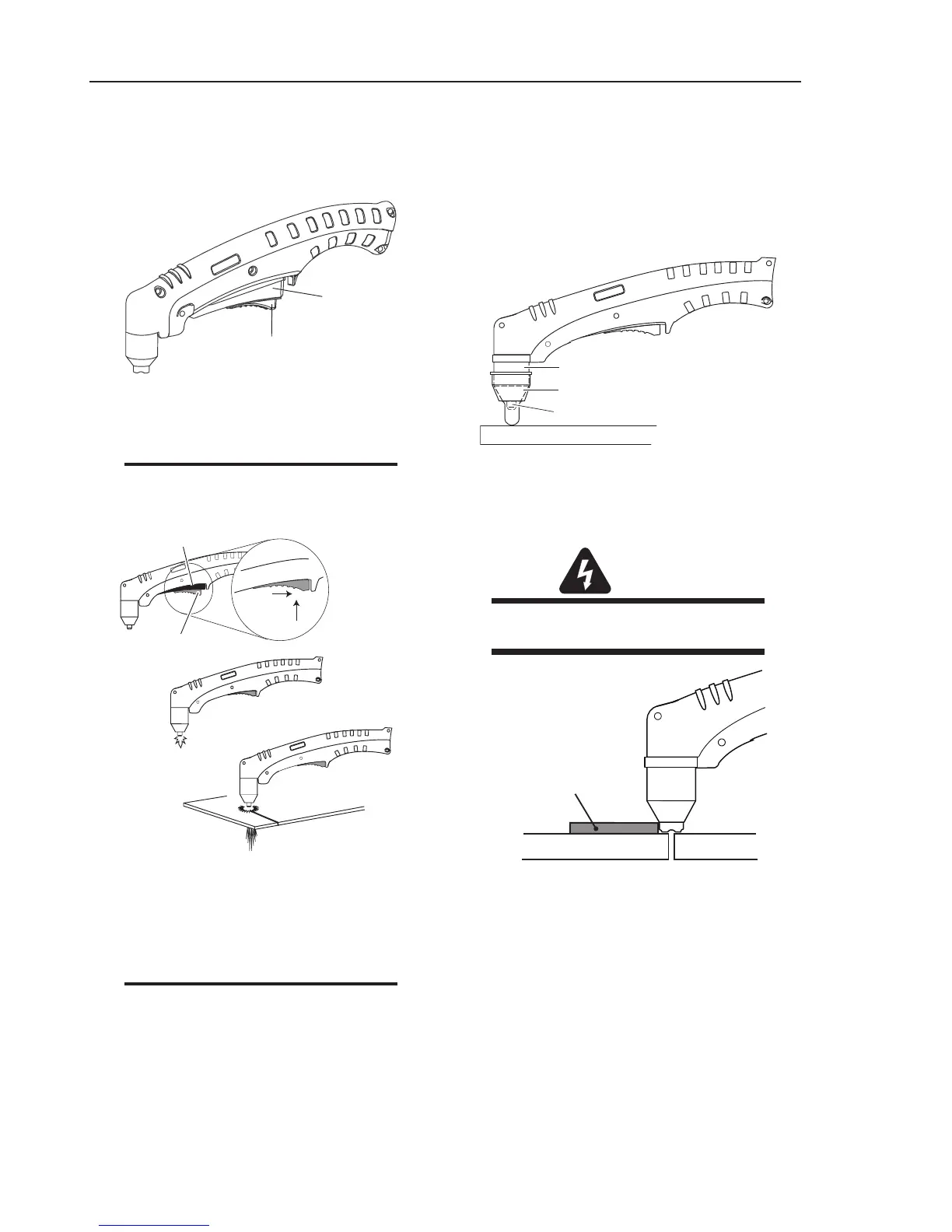

4. Slide the trigger release toward the back

of the torch handle while simultaneously

squeezing the trigger. The pilot arc will

start.

5. Bring the torch within transfer distance to

the work. The main arc will transfer to the

work, and the pilot arc will shut off.

NOTE

The gas preflow and postflow are a characteristic

of the power supply and not a function of the

torch.

6. Cut as usual. Simply release the trigger

assembly to stop cutting.

7. Follow normal recommended cutting

practices as provided in the power supply

operator's manual.

NOTE

When the shield cup is properly installed, there

is a slight gap between the shield cup and the

torch handle. Gas vents through this gap as part

of normal operation. Do not attempt to force the

shield cup to close this gap. Forcing the shield

cup against the torch head or torch handle can

damage components.

8. For a consistent standoff height from the

workpiece, install the standoff guide by

sliding it onto the torch shield cup. Install

the guide with the legs at the sides of the

shield cup body to maintain good visibility

of the cutting arc. During operation, posi-

tion the legs of the standoff guide against

the workpiece.

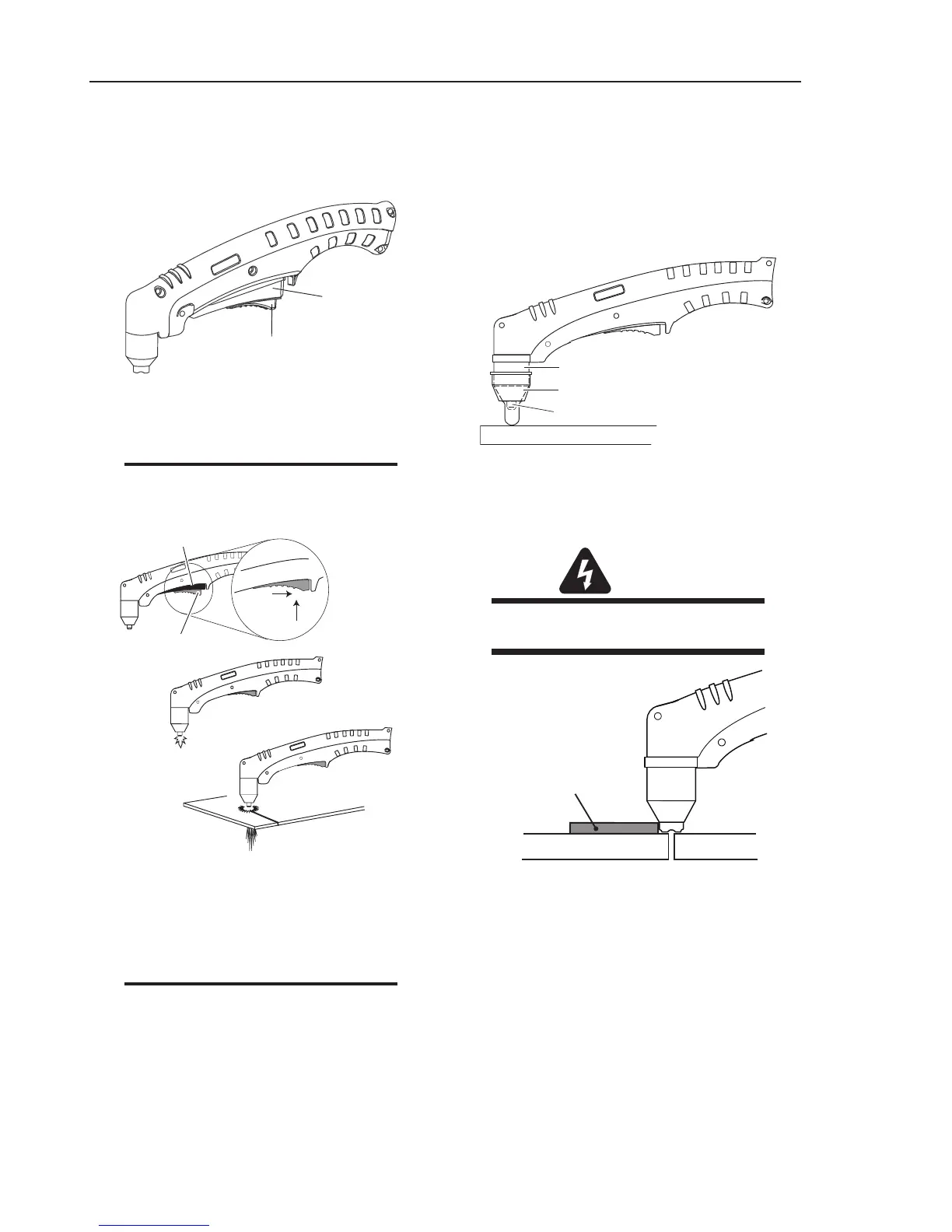

Shield Cup With Straight Edge

The drag shield cup can be used with a non con-

ductive straight edge to make straight cuts by

hand.

WARNING

The straight edge must be non - conduc-

tive.

Using Drag Shield Cup With Straight Edge

The crown shield cup functions best when cutting

3/16 inch (4.7 mm) solid metal with relatively

smooth surface.

Loading...

Loading...