1-21

C3718

C3719

C3724

Disassembly Repair 175

(cont’d)

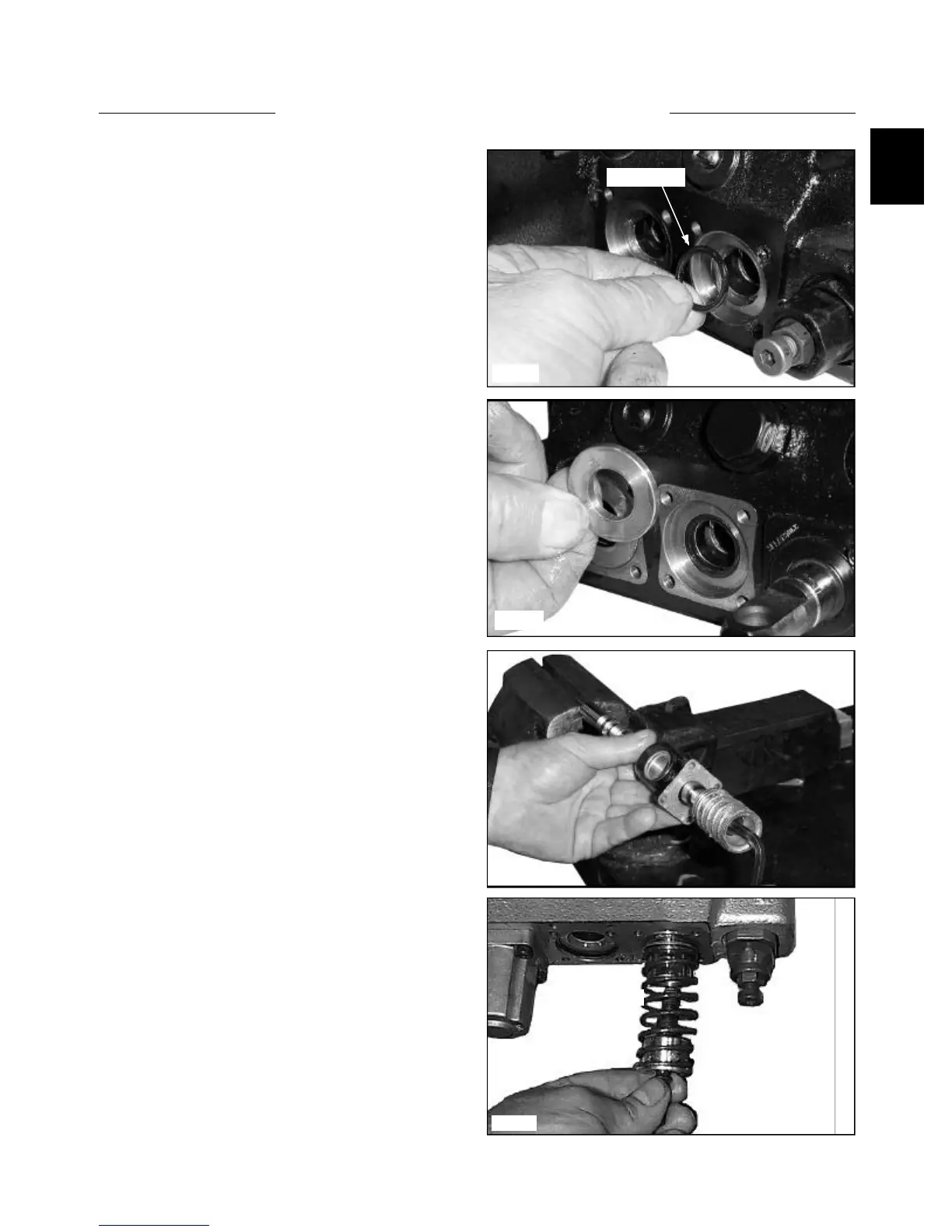

7 When replacing the spool to the control valve, use

new O-ring seals and apply system oil to the O-rings and

spools. (fig. C3718).

9 Place the cable end of the spool in a vice, or insert a

screw driver through the clevis pin holes, to keep it from

turning. The detent is threaded to the spool and can be

removed for inspection or repairs.(fig. C3724)

Replace broken springs, worn detents and / or damaged

detent balls with a new detent kit.

Apply Loctite 542 to the threads of the detent when

installing to the spool.

Apply Castrol “Spheerol” TN grease to the inside of the

spring cover.

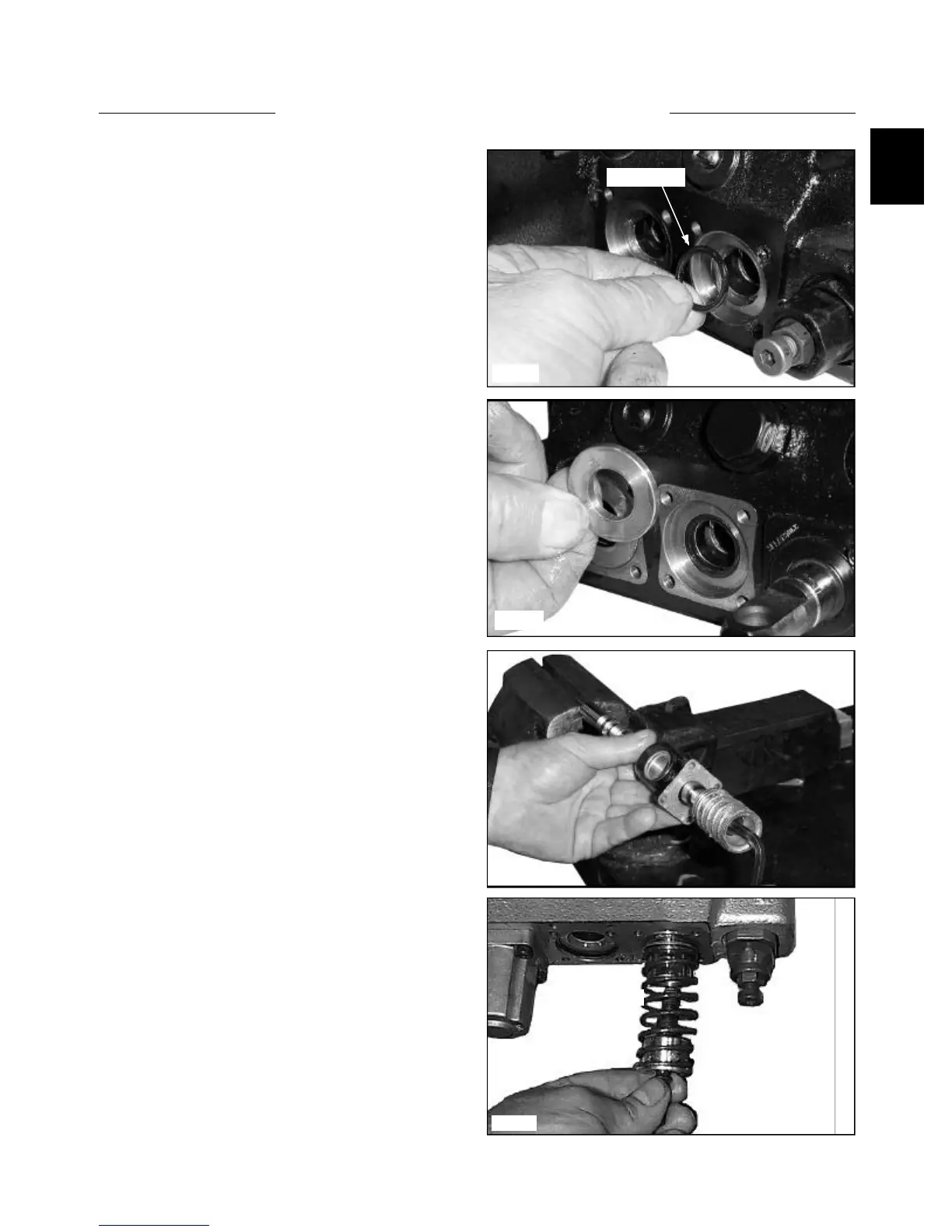

8 Fit the seal washer to the control valve with the

beveled side of the washer facing the control valve. (fig.

C3719) Fit the spool to the control valve now if repairs

are not needed to the detent or spring return mechanism.

Use system oil to lubricate the spool before inserting to

the control valve.

CONTROL VALVE 1.3

Spool O-Ring

10 When installing the detent to the control valve spool,

apply Loctite type (542) to the threads. Tighten the detent

to the spool at 24 Nm (17.7 lbs / ft). (fig. C2254)

C2254

Apply Loctite 252

Loading...

Loading...