49

Grade Setting Error

Perform the following check only after completing “Horizontal Calibration” and

“Horizontal Rotation Cone Error”.

(1) Checking

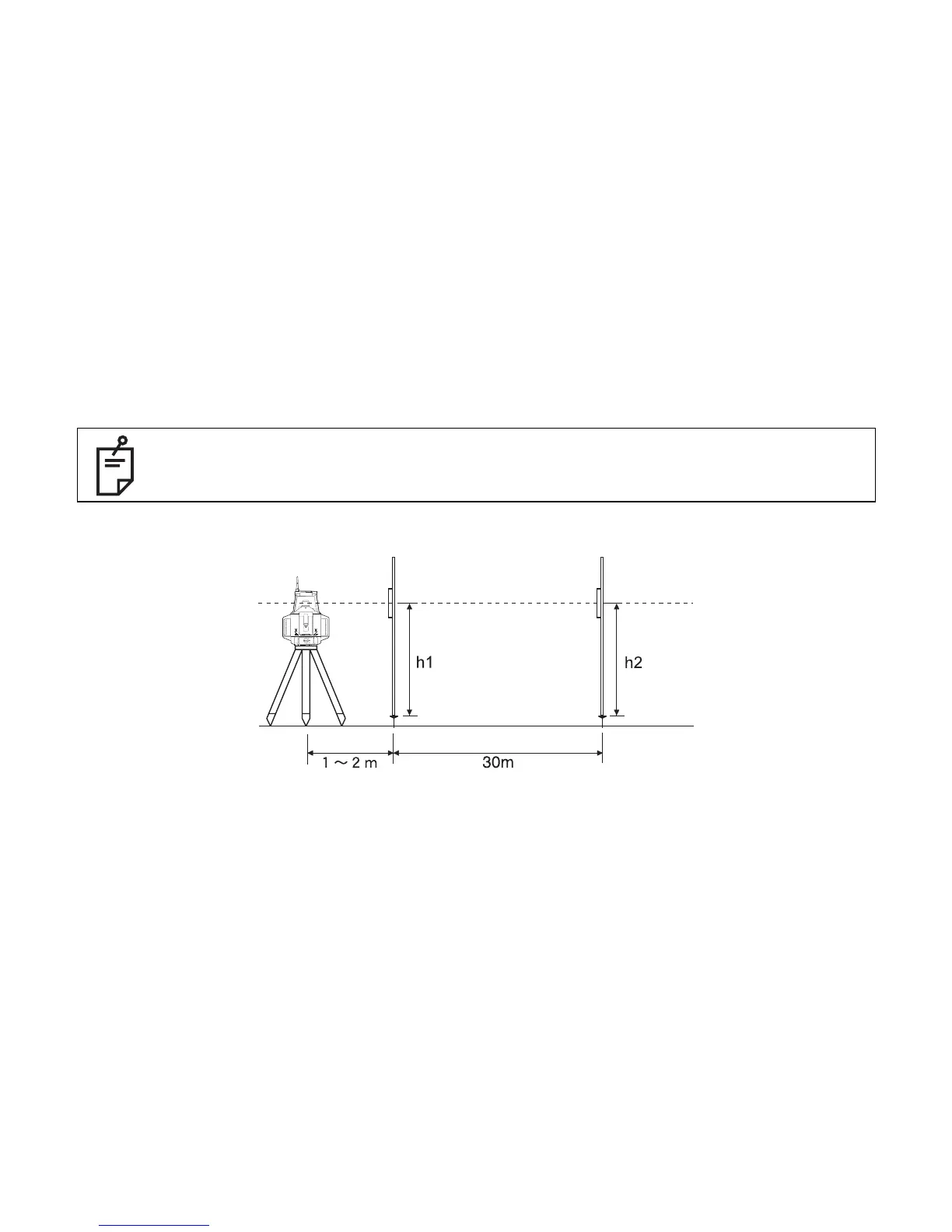

1 Securely position two nails or stakes exactly 30m (93 ft) apart. These positions will be called

Nail 1 and Nail 2.

2 Set up the instrument on a tripod approximately 1m to 2m (3 ft to 6 ft) in front of Nail 1 on the

line created by Nail 1 and Nail 2. Position the instrument so the “X-” axis is directly on the line

created by Nail 1 and Nail 2.

3 Turn on the instrument and verify the grade setting is 0.00% in both axes. Turn on the LS-70A

laser sensor and set it to high precision detection. Using the staff, read the elevation of the

laser beam in millimeters at Nail 1 and Nail 2. Designate the elevation at Nail 1 as “h1”, at Nail

2 as “h2”.

Due to the accuracy required to perform this check, the staff used in this procedure must

be graduated in millimeters.

Level

sensor

Staff

Nail 1 Nail 2

Loading...

Loading...