Chapter 7

114

UM10349_PCNC1100_Manual_0916A

Programming

7.5.16 Absolute Coordinates – G53

For rapid linear moon to a point expressed in absolute coordinates, program:

G01 G53 X~ Y~ Z~ (or similarly with G00 instead of G01), where all the axis words are oponal,

except that at least one must be used. The G00 or G01 is oponal if it is in the current moon mode.

G53 is not modal and must be programmed on each line on which it is intended to be acve. This

produces coordinated linear moon to the programmed point. If G01 is acve, the speed of moon

is the current feed rate (or slower if the mill won’t go that fast). If G00 is acve, the speed of moon

is the current traverse rate (or slower if the mill won’t go that fast).

It is an error if:

• G53 is used without G00 or G01 being acve

• G53 is used while cuer radius compensaon is on

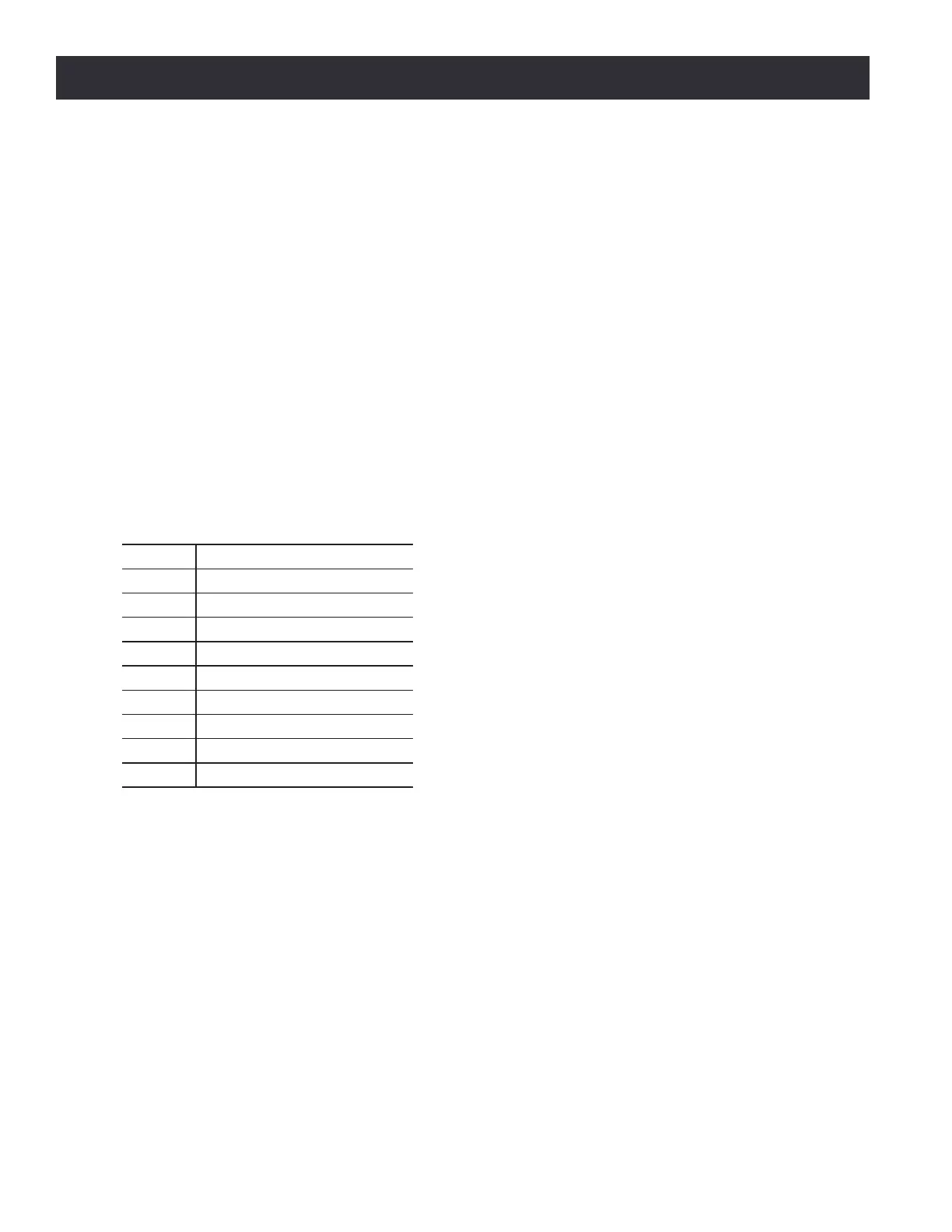

7.5.17 Select Work Offset Coordinate System – G54 to G59.3

To select a work oset coordinate system, program: G54, G55, etc, as dened in the table below.

GXX Denition

G54 Select Coordinate System 1

G55 Select Coordinate System 2

G56 Select Coordinate System 3

G57 Select Coordinate System 4

G58 Select Coordinate System 5

G59 Select Coordinate System 6

G59.1 Select Coordinate System 7

G59.2 Select Coordinate System 8

G59.3 Select Coordinate System 9

It is an error if:

• One of these G-codes is used while cuer radius compensaon is on

The X- and Z-axis work oset values are stored in parameters corresponding to the system in use

(e.g. System 1 X=5221, Z=5223; System 2 X=5141, Z=5143; up to System 9 X= 5381, Z = 5383).

7.5.18 Set Exact Path Control Mode – G61

To put the machining system into exact path mode, program: G61

Loading...

Loading...