Chapter 10

181

UM10349_PCNC1100_Manual_0916A

Troubleshooting

10.5.1 Power Distribution Subsystem

10.5.1.1 Overview

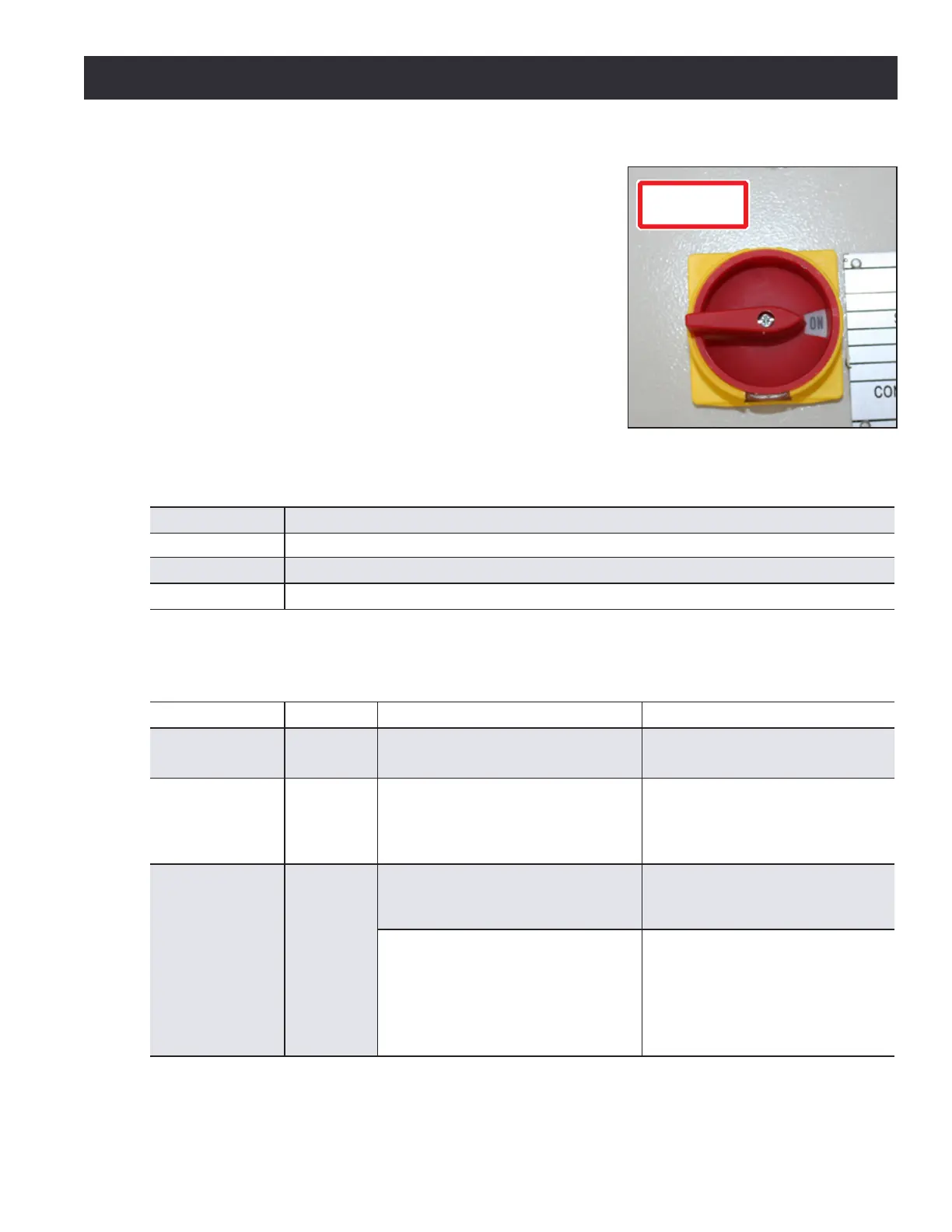

Operator supplied electrical power is run through the Main

Disconnect on the mill (see Figure 10.4). This switch controls

all power to the mill and the controller.

Below is the Problem Resoluon Checklist secon. For more

in depth explanaon of this subsystem, refer to the details

secon that follows.

Contents of Power Distribution Subsystem Problem Resolution Checklist

Table 1.1 GFI in customer supply for power for the controller and coolant pump trips

Table 1.2 Controller will not power on

Table 1.3a Coolant pump will not run when coolant switch is in the on position

Table 1.3b Coolant pump will not run when coolant switch is in the auto position

Power Distribution Subsystem Checklist

Table 1.1

GFI in customer supply for power for the controller and coolant pump trips

Possible Cause Probability

Action to Identify Cause of Problem

Discussion

GFI circuit

defective

High

Test a device such as a drill or other

portable tool on the circuit.

If the tool works, the circuit is

likely OK.

Loose wires in

circuit

Medium

Power off the mill following the

power off/on procedure detailed in

chapter 3, Installation, and test for

loose wires.

Use the two nger tug test. Refer

to Frequently Found Problems.

Defective control

board

Low

Power off the mill following the

power off/on procedure detailed in

chapter 3, Installation.

You can also unplug the power

cord for the mill.

Remove wires 202 and 205 from

the control board. Tape each wire

individually so it cannot short out, and

power the mill on following power

off/on procedure detailed in chapter

3, Installation..

If the problem disappears, a control

board problem is indicated. You

can run the mill by controlling the

coolant pump in manual until your

are able to replace the control board.

Figure 10.4

Main

Disconnect

Loading...

Loading...