Chapter 6

71

UM10349_PCNC1100_Manual_0916A

PathPilot Interface

6.7 Conversational Tab

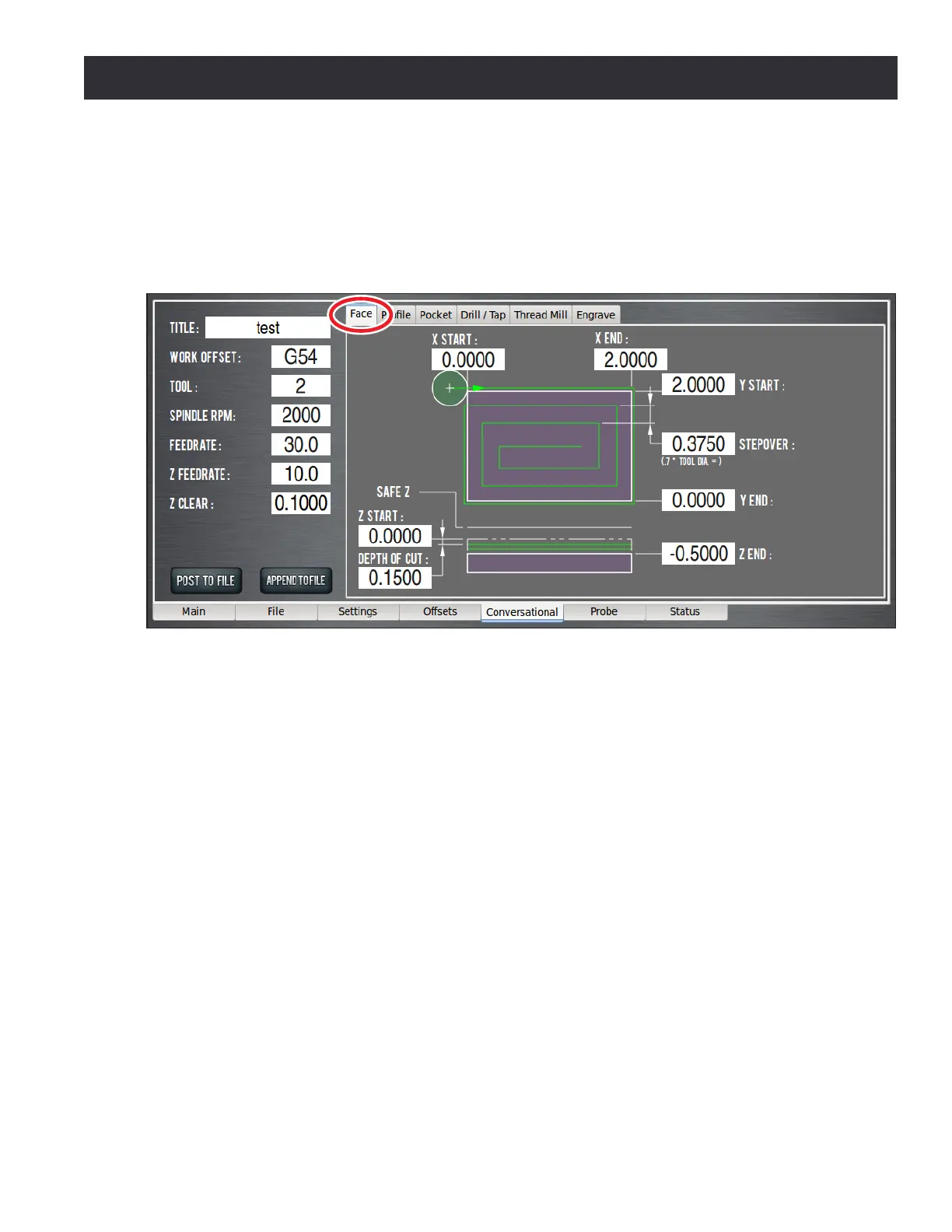

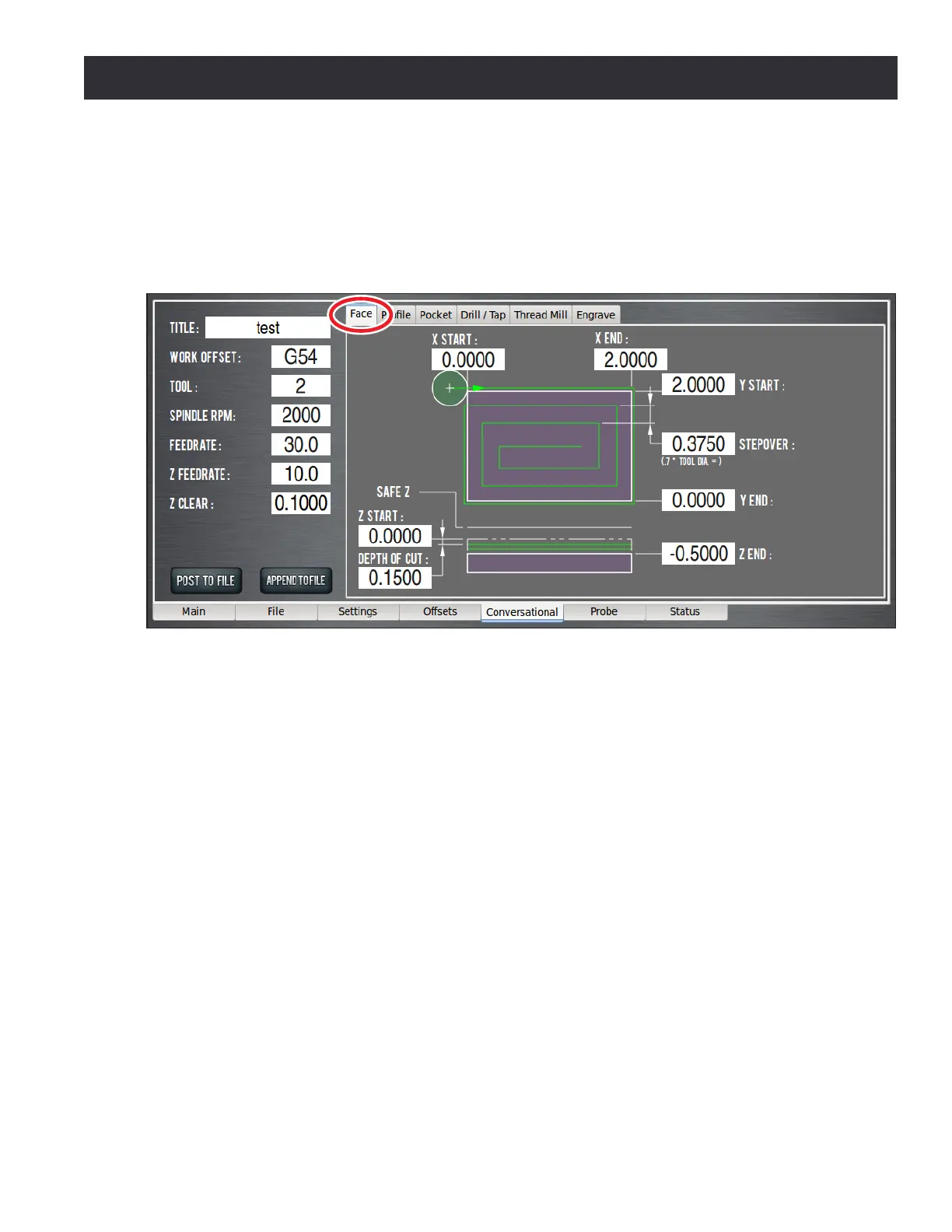

6.7.1 Face Tab

Face is generally used for cung an accurate top surface from rough stock, cung successive

XY-planes over a Z range (see Figure 6.20).

It is assumed that the top of the stock is free of any clamps or other work holding devices, such

as when the stock is held in a vise. The start of each Z pass is intended to be o to the side of the

workpiece then move in XY to start cung at the X Start, Y Start corner. This avoids the need for

plunging the Z Depth of Cut move into the workpiece.

Therefore, the area around this corner must be clear of obstrucons down to Z End. The tool

diameter also extends beyond the workpiece X and Y edges by an amount dependent on the tool

diameter and the stepover values, so Z End must be above the vise jaws.

The G-code roune starts with a move to G30, which typically is the park, or tool change posion.

Next comes a tool change if needed, a rapid move in XY to the workpiece start, and a rapid down

in Z to Z Clear. An XY pass starts with an adjusted Z Depth of Cut, then a rectangular spiral from the

workpiece perimeter, ending at the center. If a nish pass with dierent parameters is needed, save

the current le, edit the current screen to the nish conguraon and append to the saved le.

XY DROs

Start and End – These DROs should be set to the locaon of the workpiece edges. Tool paths, such

as a lead-in, that are normally outside of the workpiece area are set in reference to these values, so

no adjusng beyond the actual locaon of these edges should be needed.

Figure 6.20

Loading...

Loading...