Chapter 9

168

UM10349_PCNC1100_Manual_0916A

Maintenance

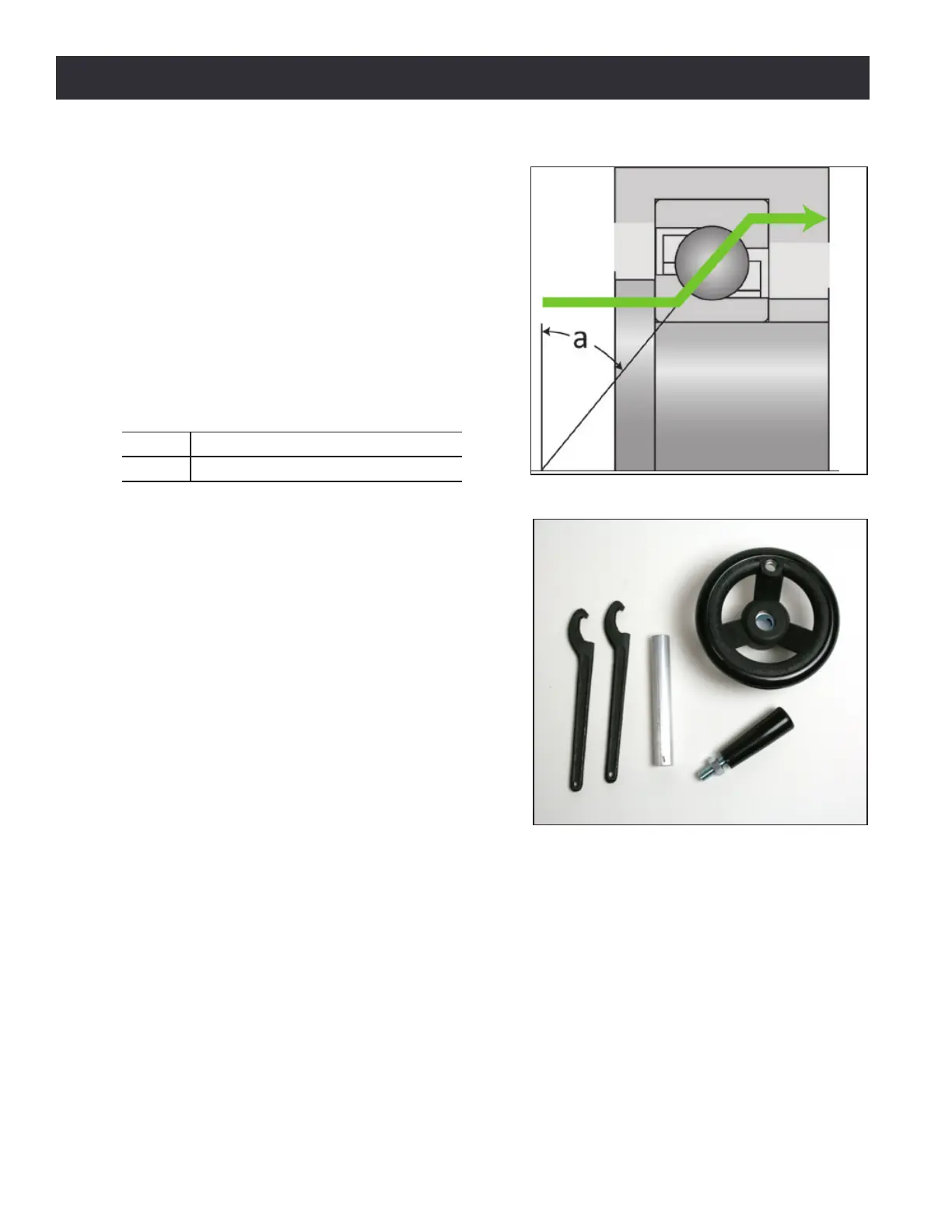

Figure 9.6 shows how the force of preload is

transmied through the bearings, from the inner

race to the outer race. In a preload pair, this force

is then transmied back to the inner race by an

opposed bearing. It should be apparent that the

correct orientaon of the angular contact bearing is

crical to the operaon.

9.3.4.2 Adjustment Procedure

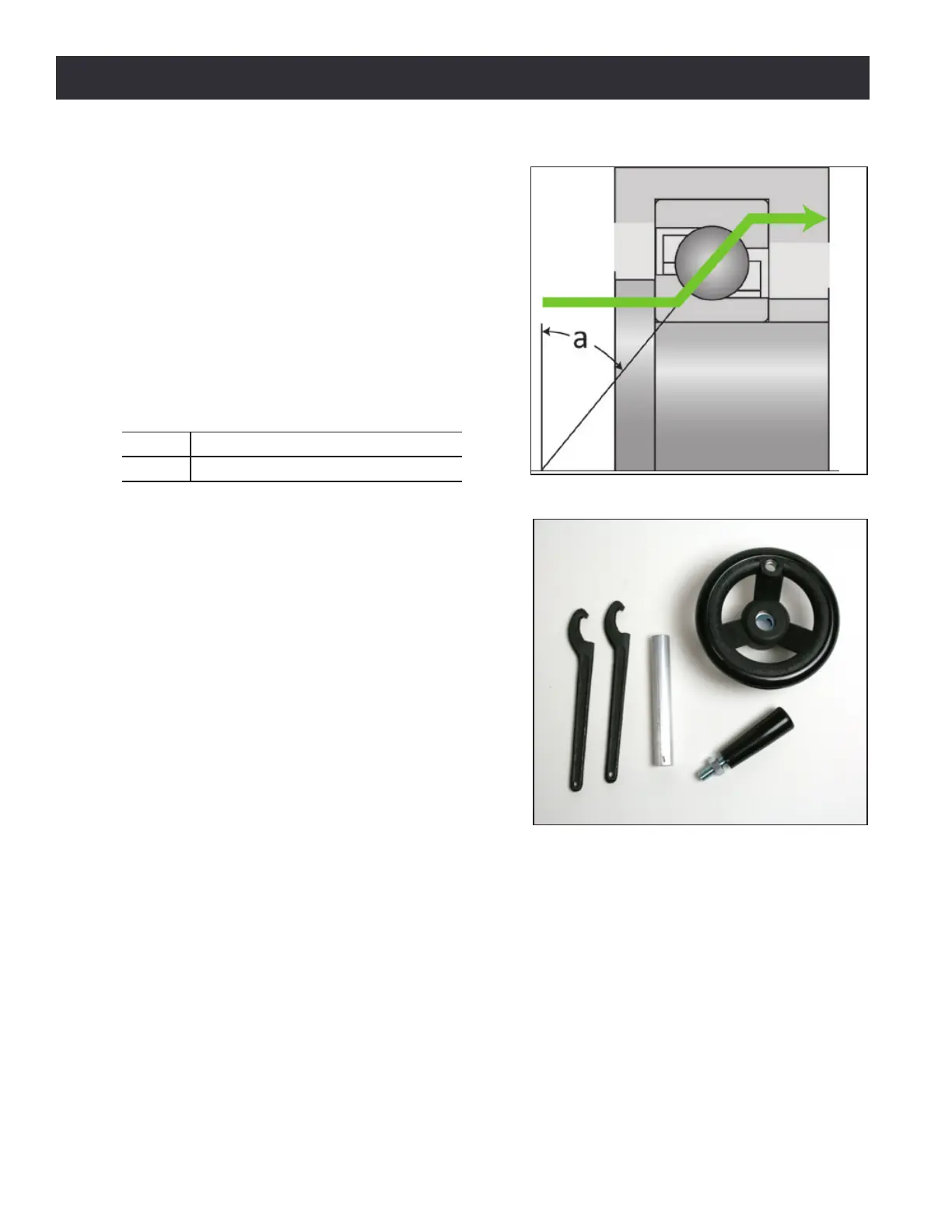

To adjust the angular contact bearing pair preload,

the following kit is required (see Figure 9.7):

PN Description

35355 AC Bearing Service Tool Kit

There are two nuts: the adjustment nut and the

lock nut. The nut nearer the bearing housing is the

adjustment nut, and the one nearer the axis motor

is the lock nut (see Figure 9.5).

NOTE: When working on the Z-axis, remove any tooling

from the spindle and support the head by resng the

spindle nose on a block of wood.

1. Loosen the lock nut and back it o about two

turns.

2. Hold the ball screw to prevent it from rotang

with a pair of pliers on the coupling and ghten

the adjustment nut unl there is slightly more

backlash than you ulmately want to achieve.

Tightening the lock nut will slightly increase

the bearing preload.

9.3.4.3 Determining Proper Angular Contact Bearing Preload

To properly esmate the torque needed to overcome angular contact bearing fricon, the bearings

must be isolated from the stepper motor detent torque. Use the following procedure:

1. For adjusng the X-axis, posion the table near the right hand end of its travel (i.e., X near to

zero). This ensures that the bearing is near to the ball nut to minimize bending of the screw

during tests.

Figure 9.6

Figure 9.7

Loading...

Loading...