Chapter 9

164

UM10349_PCNC1100_Manual_0916A

Maintenance

5. In MDI eld, program a posive X move of .01” at a feed rate of 5 IPM: G01 X.01 F5. The

spindle head moves slightly in +X direcon. When nished, indictor should read .010”.

6. Program an X move back to 0: G01 X0 F5. The spindle head moves slightly in the -X direcon.

The X DRO should say 0; however, the dial indicator should read a number very close to 0. This

value is the measured lost moon.

9.3.3 Gib Adjustment

9.3.3.1 Overview

PCNC mills use dovetail-gibbed ways to guide the X-, Y-, and Z-axis moon.

Over me, the dovetail ways and gibs wear from sliding fricon and it may be necessary to ghten

the gib to reduce axis backlash. To compensate for wear, the design of a dovetail-gibbed way allows

for the posion of the gib to be adjusted to maintain an appropriate sliding clearance.

A properly adjusted gib minimizes lost moon by balancing convenonal backlash and sliding

fricon. A gib that is too loose results in excessive convenonal backlash; a gib that is too ght

cannot adequately support an oil lm resulng in excessive sliding fricon.

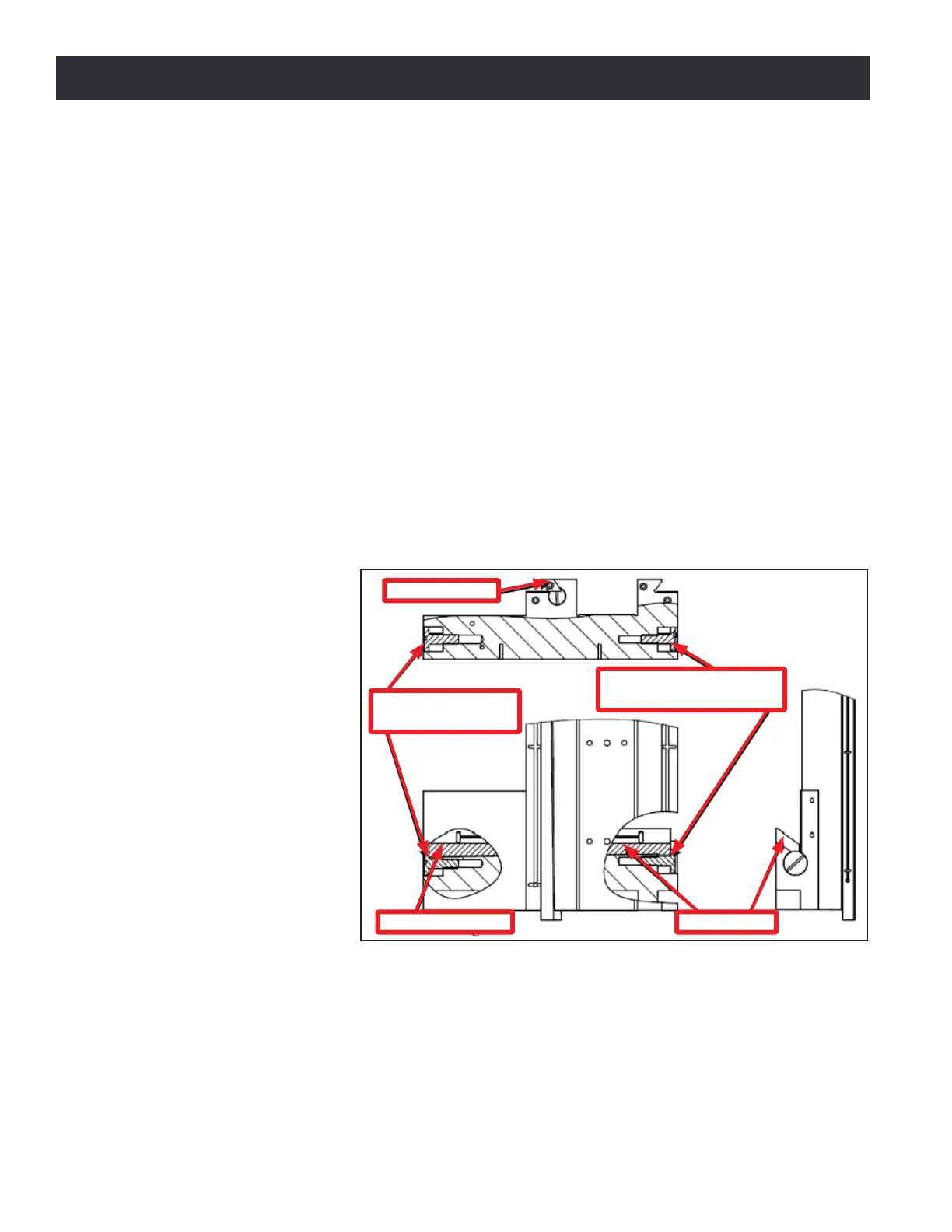

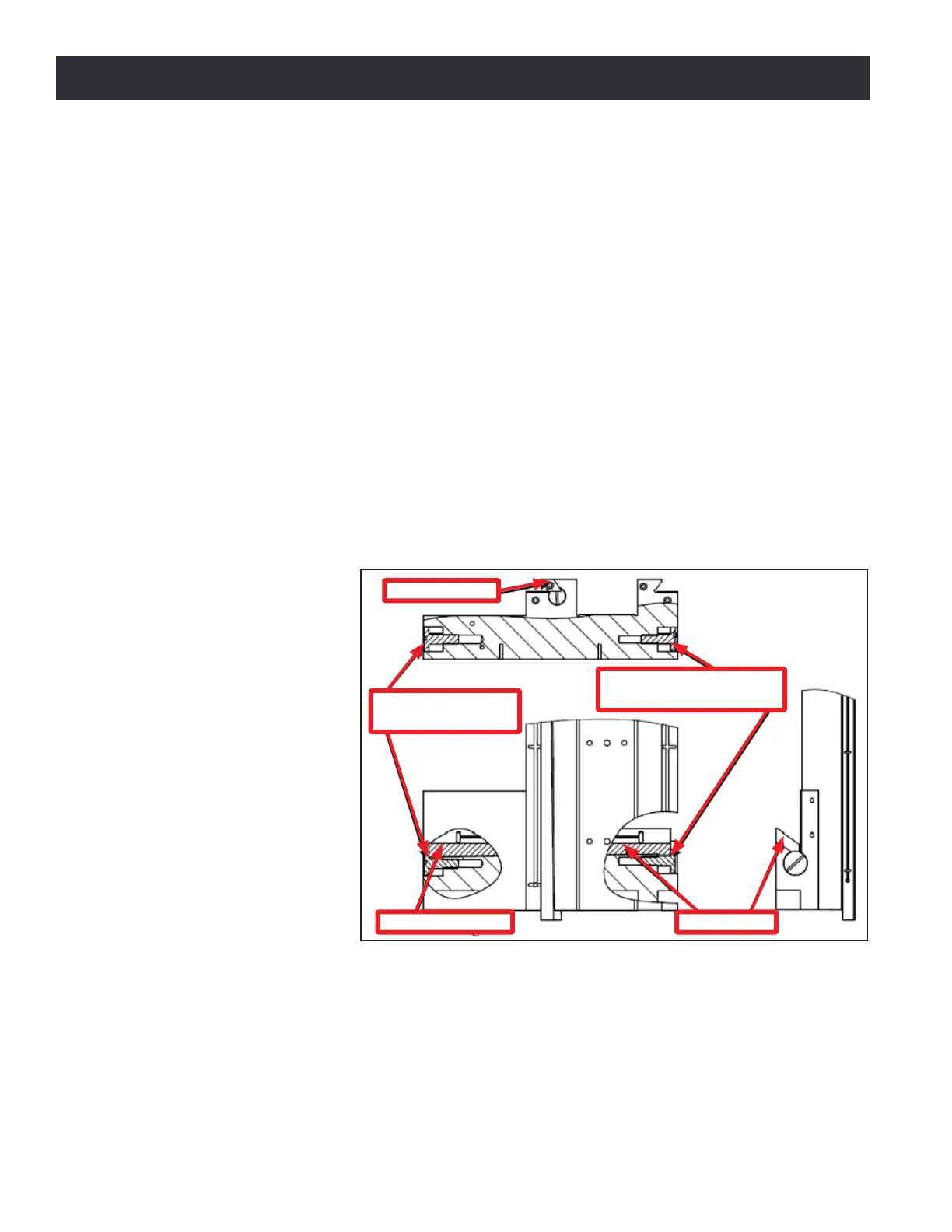

The posion of the tapered

gib plate is controlled by two

screws on either end of the

gib that capture the posion

of the gib with respect to the

saddle. These screws can be

adjusted (as a pair) to tune

the ghtness and sliding

fricon of the dovetail

way for each axis. Figure

9.2 shows the Y-axis gib

mechanical detail; the X- and

Z-axis have similar detail.

Figure 9.2

Thick end of gib Tapered gib

Counterclockwise on

screw loosens slide

Gib for X slide

Clockwise on screw

tightens slide

Loading...

Loading...