Chapter 7

89

UM10349_PCNC1100_Manual_0916A

Programming

It is possible, however, to control the axes so that, at all mes, each axis has completed the same

fracon of its required moon (as the other axes) and the tool maintains a straight line moon.

Arc and Helical Moon

Any pair of the linear axes (XY, YZ, and XZ) can be controlled to move in a circular arc in the plane

of that pair of axes. While this is occurring, the third linear axis and/or the rotaonal axes can be

controlled to move simultaneously at a constant rate. As in coordinated linear moon, these moons

can be coordinated so that acceleraon and deceleraon do not aect the path. If the third linear

axis moves simultaneously with arc moon, the trajectory of the controlled point forms a helix.

Feed Rate

The feed rate is the nominally steady rate at which the controlled point moves. Feed rates are

programmed by the operator. The interpretaon of the feed rate is detailed in the table below.

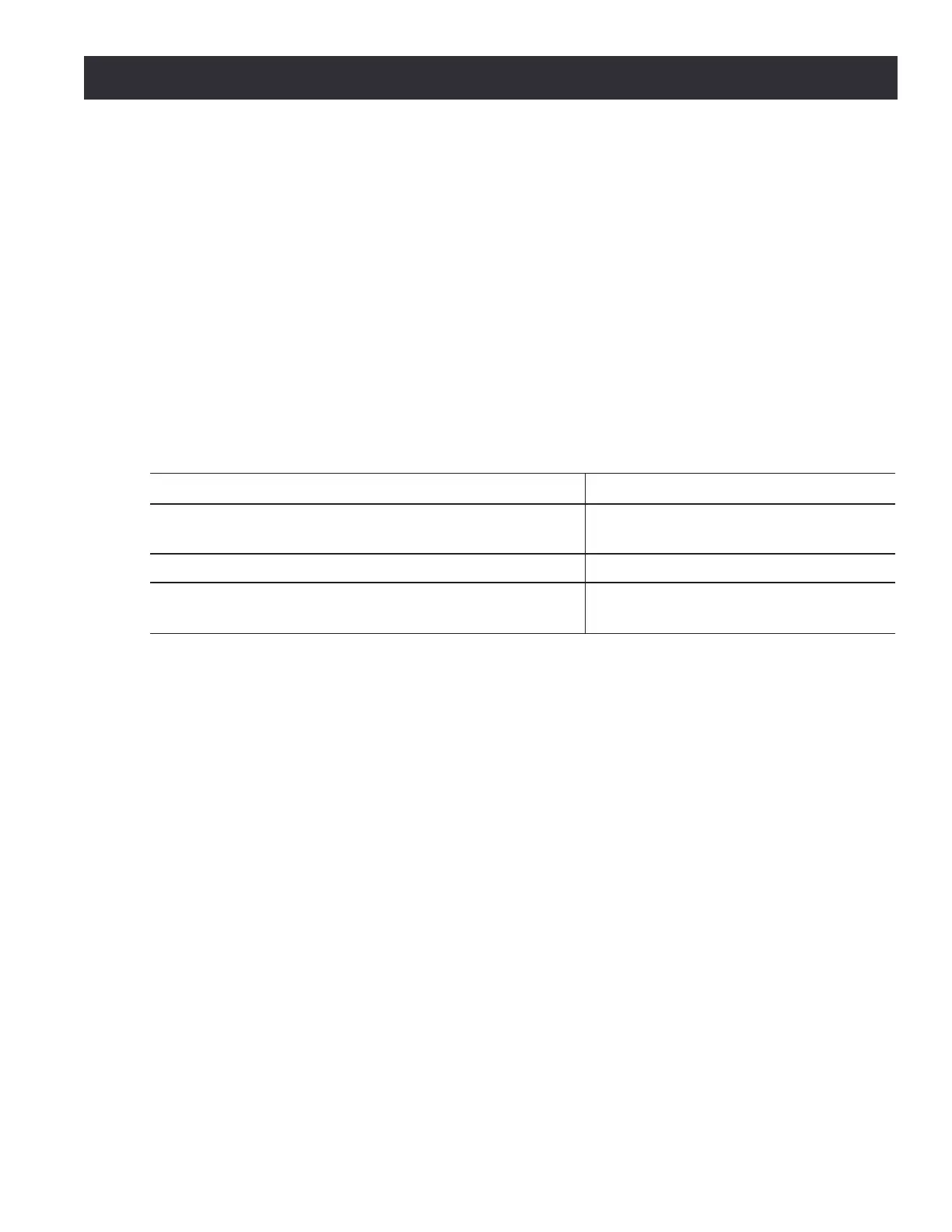

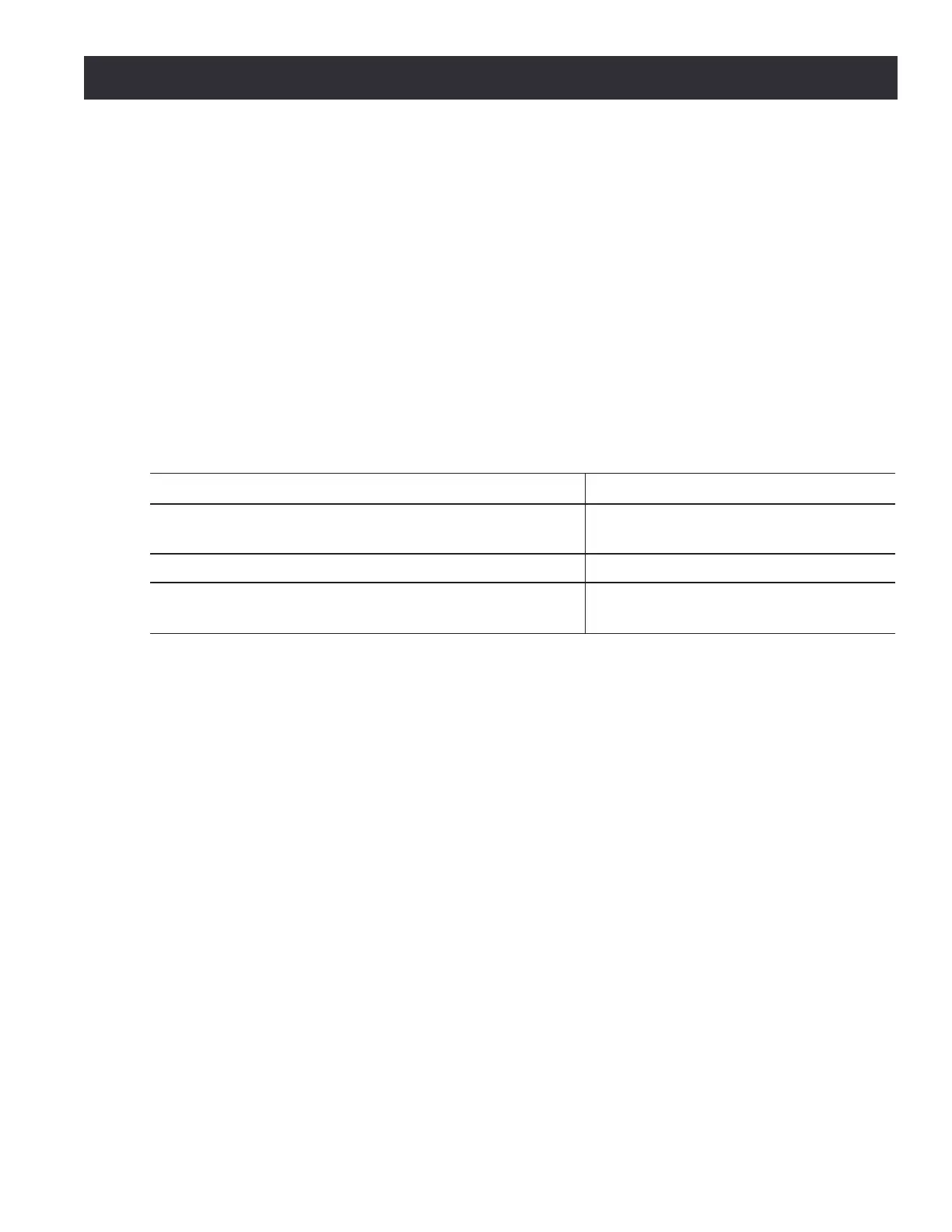

Motion Feed Rate

Coordinated linear motion of one or more axis (X-, Y-, or

Z-axis)

Inches per minute (G20 mode) or

millimeters per minute (G21 mode)

Rotational axis motion of one axis (A-axis) Degrees per minute

Coordinated linear motion of one or more axis (X-, Y-, or

Z-axis) with simultaneous rotational axis motion (A-axis)

This type of motion is usually programmed

in inverse time feed rate mode (G93)

Dwell

Commanding a dwell pauses the moon of the axes for a specic amount of me. The units in which

you specify dwell are seconds; a decimal value is used to get less than one second.

Work Osets

Work osets allow you assign an origin to any locaon within the work envelope.

Up to nine dierent work osets can be saved in the mill memory, but only one can be acve at any

given me. The default work oset is G54. The posion of each work oset origin is stored in the

Work Oset Table.

Tool Number

The tool number is used to idenfy a tool in a program. Each tool used in the program must have a

unique tool number between 1 and 256.

Tool Table

The tool table stores the tool diameter value and tool length oset value associated with each tool

number. The diameter value is used for cuer radius compensaon. The tool length oset value is

used to adjust the posion of the controlled point for dierences in the lengths among tools.

Loading...

Loading...