HydraulicSystem

Maintenance

ServicingtheHydraulic

System

Themachinecomesfromthefactorywithafullhydraulic

uidreservoirthatcontainsapproximately182L(48US

gal)ofhigh-qualityhydraulicuid.Checkthelevelofthe

hydraulicuidbeforeyoustarttheenginefortherst

time,anddailythereafter.

UseToroPremiumAll-seasonHydraulicFluid(available

in5-gallonpailsor55-gallondrums.Seethepartscatalogor

anAuthorizedToroServiceDealerforpartnumbers).

IfTorohydraulicuidisnotavailable,youmayusean

equivalenthydraulicuid,providedthatitmeetsallthe

followingmaterialpropertiesandindustryspecications.Do

notuseasynthetichydraulicuid.Consultwithyour

lubricantdistributortoidentifyasatisfactoryproduct.

Note:Torodoesnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproductsfrom

reputablemanufacturers.

HighViscosityIndex/LowPourPoint

Anti-wearHydraulicFluid,ISOVG46

MaterialProperties:

St@40°C(104°F):44to48 Viscosity,ASTMD445

St@100°C(212°F):7.9to8.5

ViscosityIndexASTM

D2270

140to160

PourPoint,ASTMD97-37°C(-34°F)to-45°C(-49°F)

FZG,Failstage

11orbetter

Watercontent(newuid)500ppm(maximum)

IndustrySpecications:VickersI-286-S(QualityLevel),

VickersM-2950-S(Quality

Level),DenisonHF-0

Note:Manybrandsofhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditiveforthe

hydraulicsystemoilisavailablein20ml(0.68oz)bottles.

Onebottleissufcientfor15.1to22.7L(4.0to6.0USgal)

ofhydraulicoil.Orderpartno.44-2500fromanAuthorized

ToroServiceDealer.

Note:Ifambientoperatingtemperaturesexceed110°F,

contactToroforuidrecommendations.

ChangingtheHydraulicFluidand

ReplacingtheBreather

ServiceInterval:Every1,000hours

Thecapacityofthehydraulic-uidreservoir:150L(40

USgallons)

Thecapacityofthehydraulic-uidsystem:182L(48

USgallons)

DrainingtheHydraulicReservoir

Note:Drainthehydraulicuidreservoirwhentheuidis

warm,ifpossible.

1.Removetherightsidepanel;refertoRemovingthe

SidePanels(page45).

2.RotatethebatterydisconnecttotheOffposition

(Figure107).

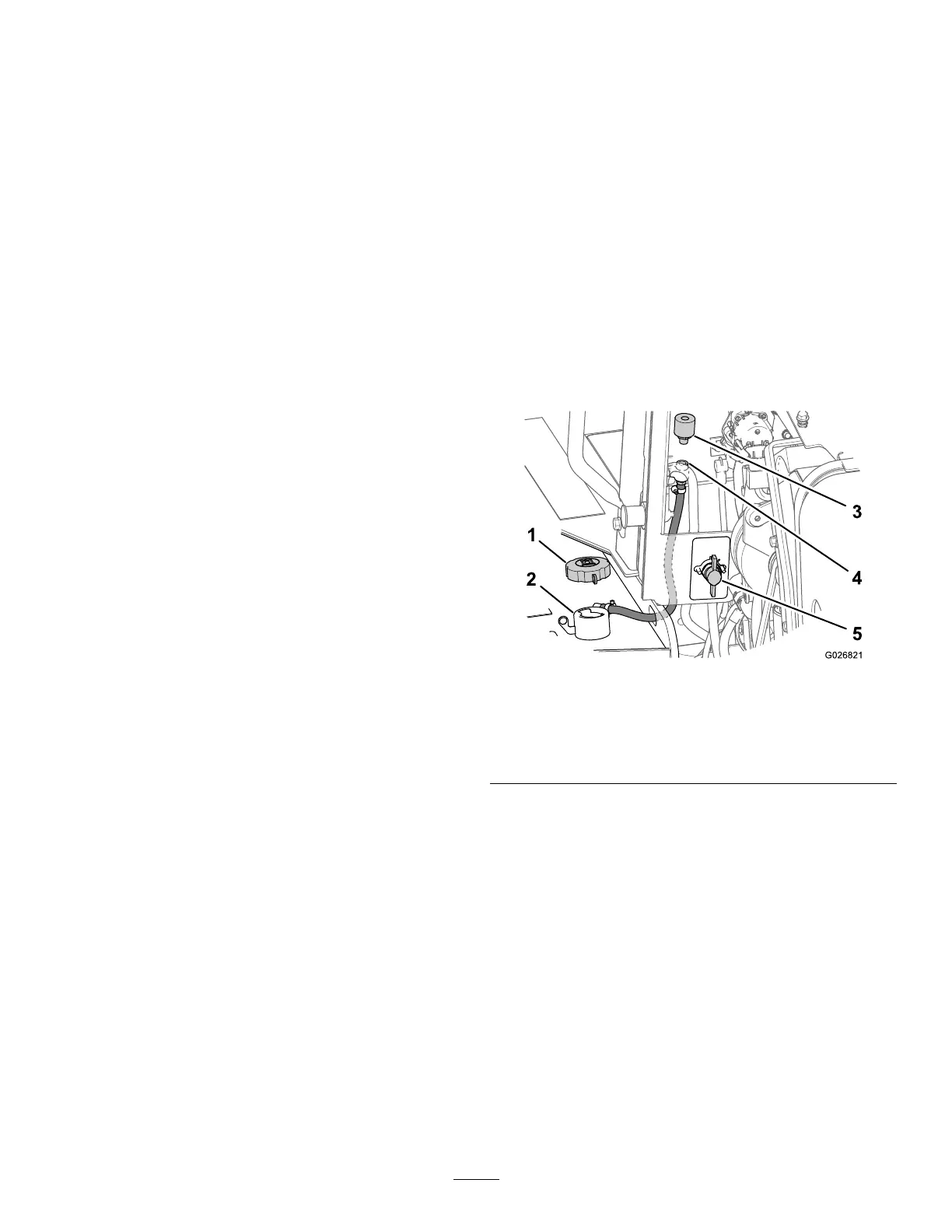

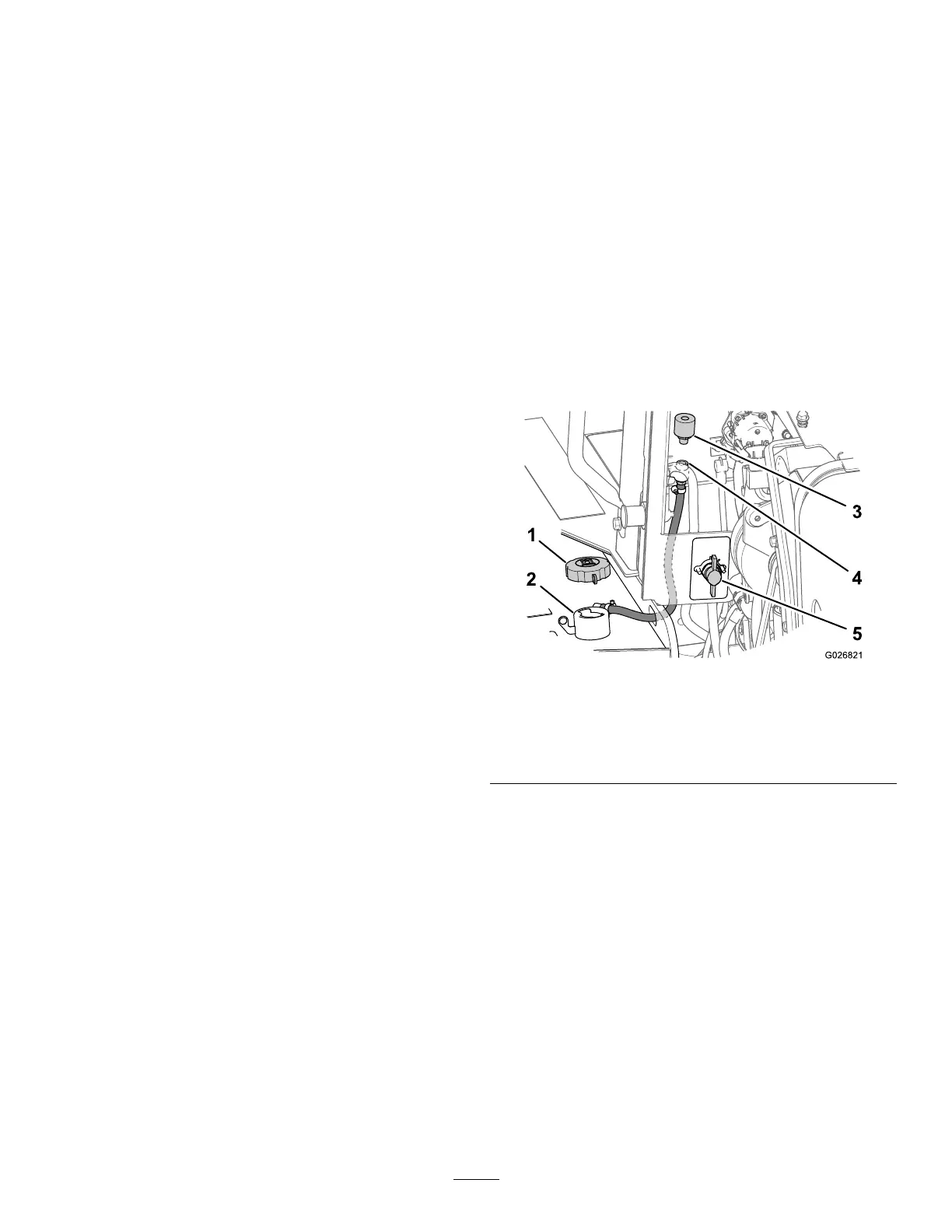

Figure107

1.Fillcap(hydraulictank)

4.Pipecoupling

2.Fillerneck(hydraulictank)

5.Batterydisconnectswitch

(Offposition)

3.Breather

3.Removethellcapfromthellerneckofthetank

(Figure107).

4.Attheforwardsideoftheenginecompartmentpanel,

removethebreatherfromthepipecouplingbyrotating

thebreathercounterclockwise(Figure107).

Note:Discardtheoldbreather.

5.Installanewbreatherintothepipecouplinghandtight

(Figure107).

6.Placeacontainerthatcanholdaminimumof190L

(50USgal)underthehydraulicreservoirdrainplug

(Figure108).

70

Loading...

Loading...