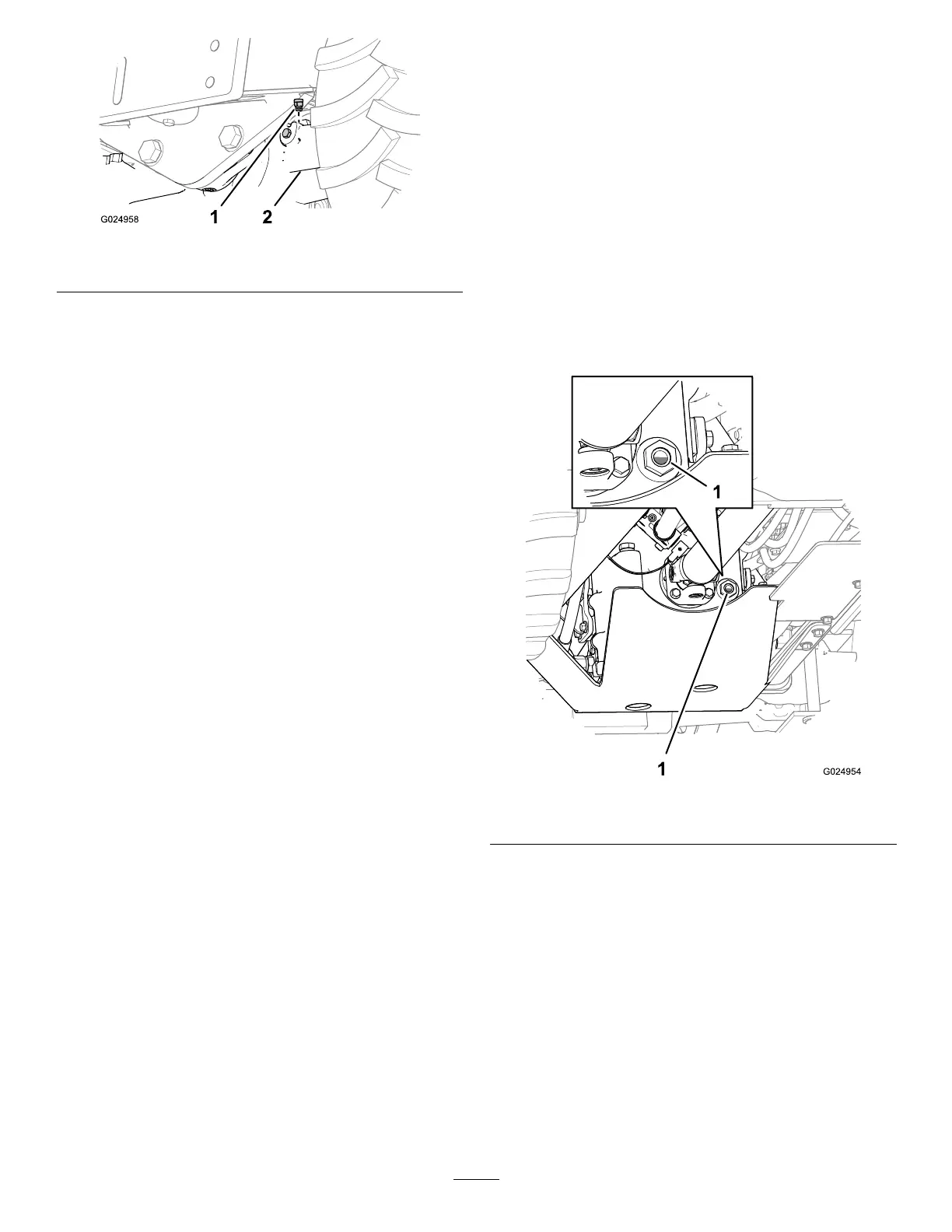

Figure93

1.Breathertting

2.Rearaxle

2.Removethebreathersfromthefrontaxleandrear

axles(Figure92andFigure93).

3.Cleanthebreatherswithacleaningsolvent.

4.Usecompressedairtodrythebreathers.

Important:Wearfaceprotectionwhenusing

compressedair.

5.Installthebreathersintothefrontandrearaxles(Figure

92andFigure93).

ServicingtheTransmission

UseToroPremiumAll-seasonHydraulicFluid(available

in5-gallonpailsor55-gallondrums.Seethepartscatalogor

anAuthorizedToroServiceDealerforpartnumbers).

IfTorohydraulicuidisnotavailable,youmayusean

equivalenthydraulicuidsuchasMobiluid424,provided

thatitmeetsallthefollowingmaterialpropertiesand

industryspecications.Donotuseasynthetichydraulic

uid.Consultwithyourlubricantdistributortoidentifya

satisfactoryproduct.

HighViscosityIndex/LowPourPoint

Anti-wearHydraulicFluid,ISOVG46

MaterialProperties:

St@40°C(104°F):44to48 Viscosity,ASTMD445

St@100°C(212°F):7.9to8.5

ViscosityIndexASTM

D2270

140to160

PourPoint,ASTMD97-37°C(-34°F)to-45°C(-49°F)

FZG,Failstage

11orbetter

Watercontent(newuid)500ppm(maximum)

IndustrySpecications:VickersI-286-S(QualityLevel),

VickersM-2950-S(Quality

Level),DenisonHF-0

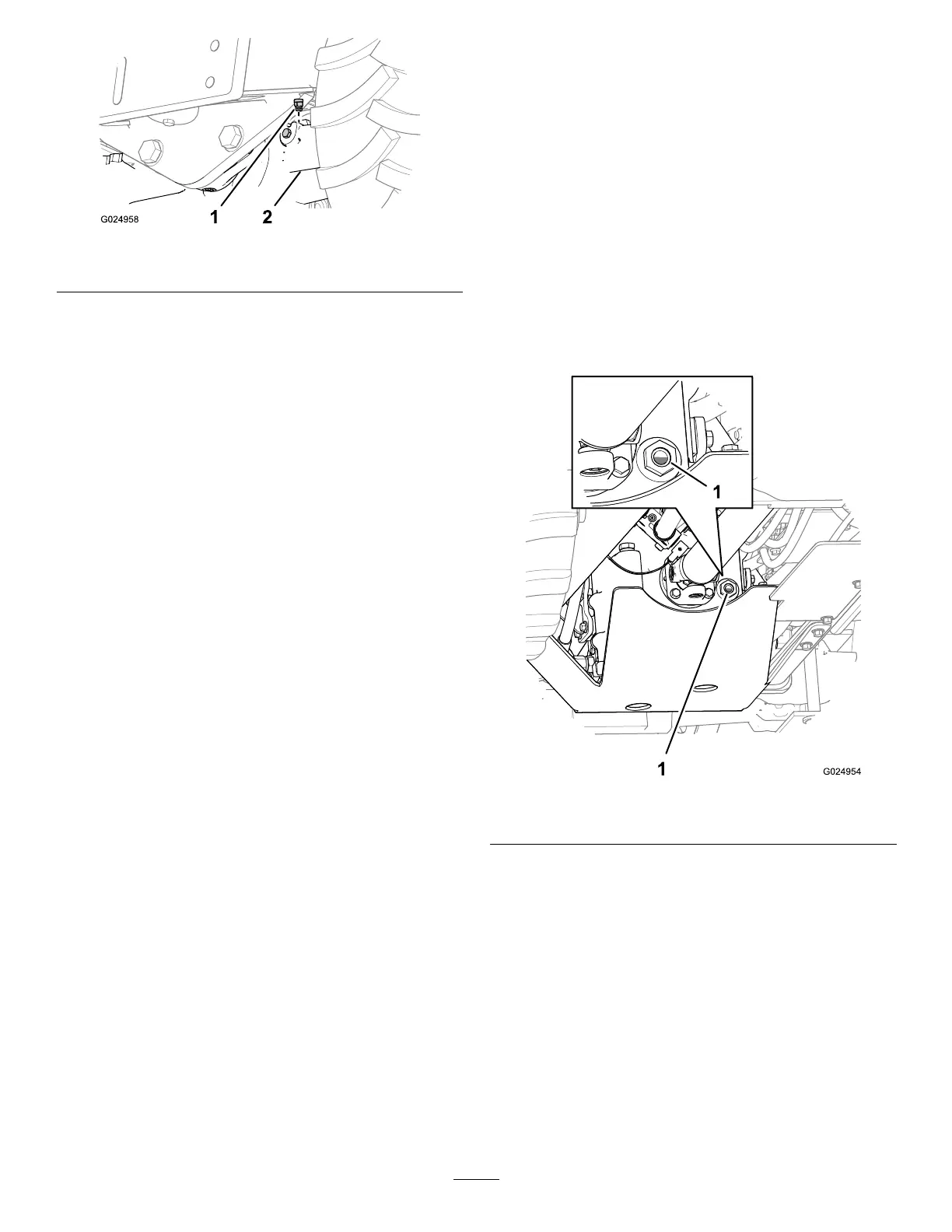

CheckingtheOilLevelinthe

Transmission

ServiceInterval:Every100hours

Important:Ifyouoperatethemachinewhilethelevelof

thetransmissionoilisbelowtherecommendedlevel,you

maydamagethetransmissionandtheparkingbrake.

1.Parkthemachineonalevelsurface.

2.Starttheengineandrunitfor10minutes.

3.Stoptheengineandremovetheignitionkey.

4.After5minutes,checkthetransmissionoillevelinthe

sightgauge(Figure94).

Note:Theoillevelshouldcover1/2to3/4ofthe

sight-gaugewindow.

Figure94

1.Sightgauge

5.Iftheoillevelislow,addoil;refertoFillingthe

TransmissionwithOil(page63).

6.Repeatsteps2through5untiltheoillevelcovers1/2

to3/4ofthesight-gaugewindow(Figure94).

Note:Asyouaddoiltothetransmission,perform

steps2through4todeterminethecorrectedoillevel.

62

Loading...

Loading...