December 2005 © TOSHIBA TEC e-STUDIO163/203 PREVENTIVE MAINTENANCE (PM)

4 - 3

4

4.3 Preventive Maintenance Checklist

Symbols used in the checklist

[Preventive Maintenance checklist]

Notes:

1. Perform cleaning and lubricating in the following timing.

Exceptionally, the lubrication for the drum unit, main charger, developer unit and transfer unit

must follow the PM cycle of each unit.

e-STUDIO163: every 72,000 sheets

e-STUDIO203: every 90,000 sheets

2. Value under “Replacement” indicates the replacement cycle for e-STUDIO163/

e-STUDIO203.

3. The replacement cycle of the parts in the feeding section equals to the number of sheets fed

from each paper source.

4. Be careful not to put oil on the rollers, belts and belt pulleys when lubricating.

5. Page-Item (P-I) is described in the column of the Parts list.

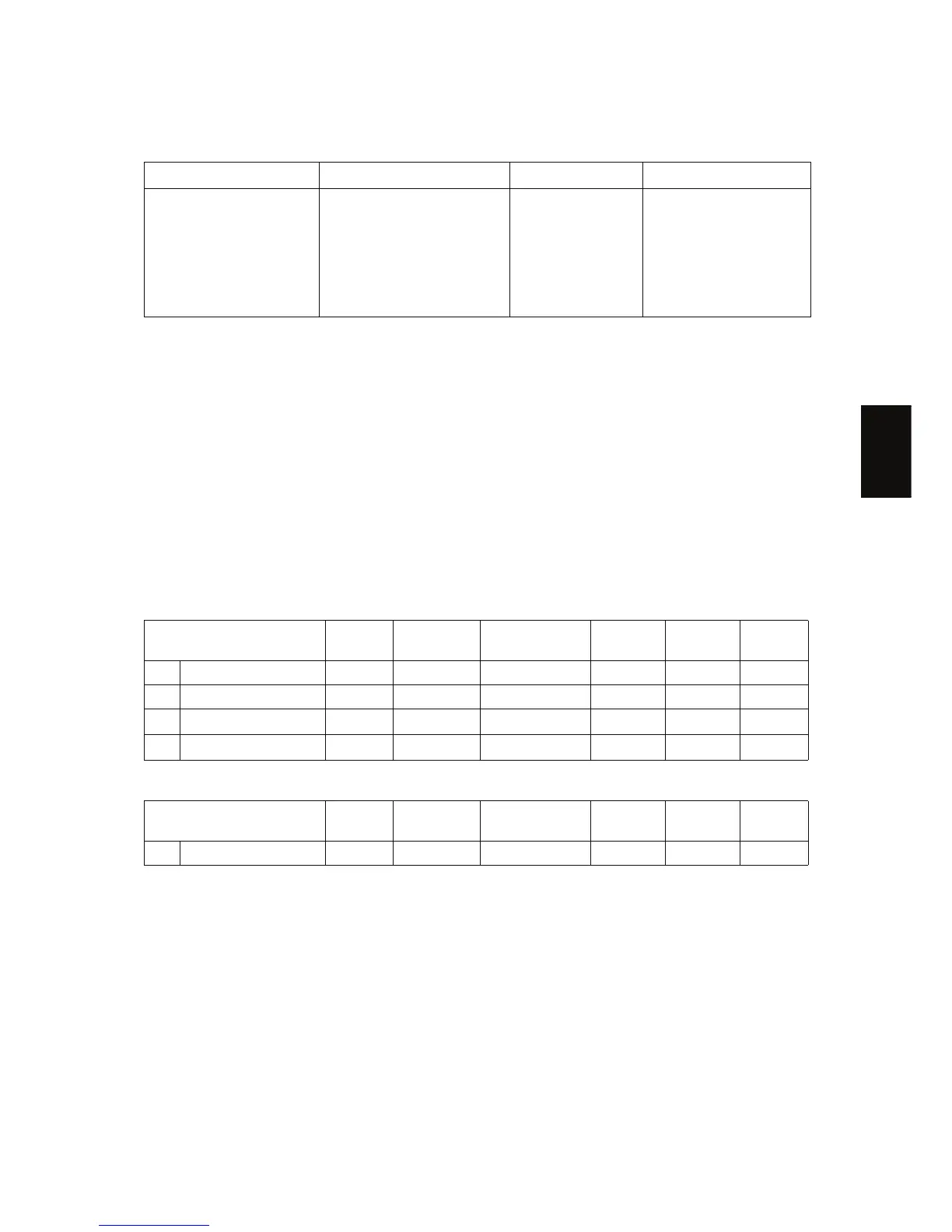

A. Scanner

B. Laser unit

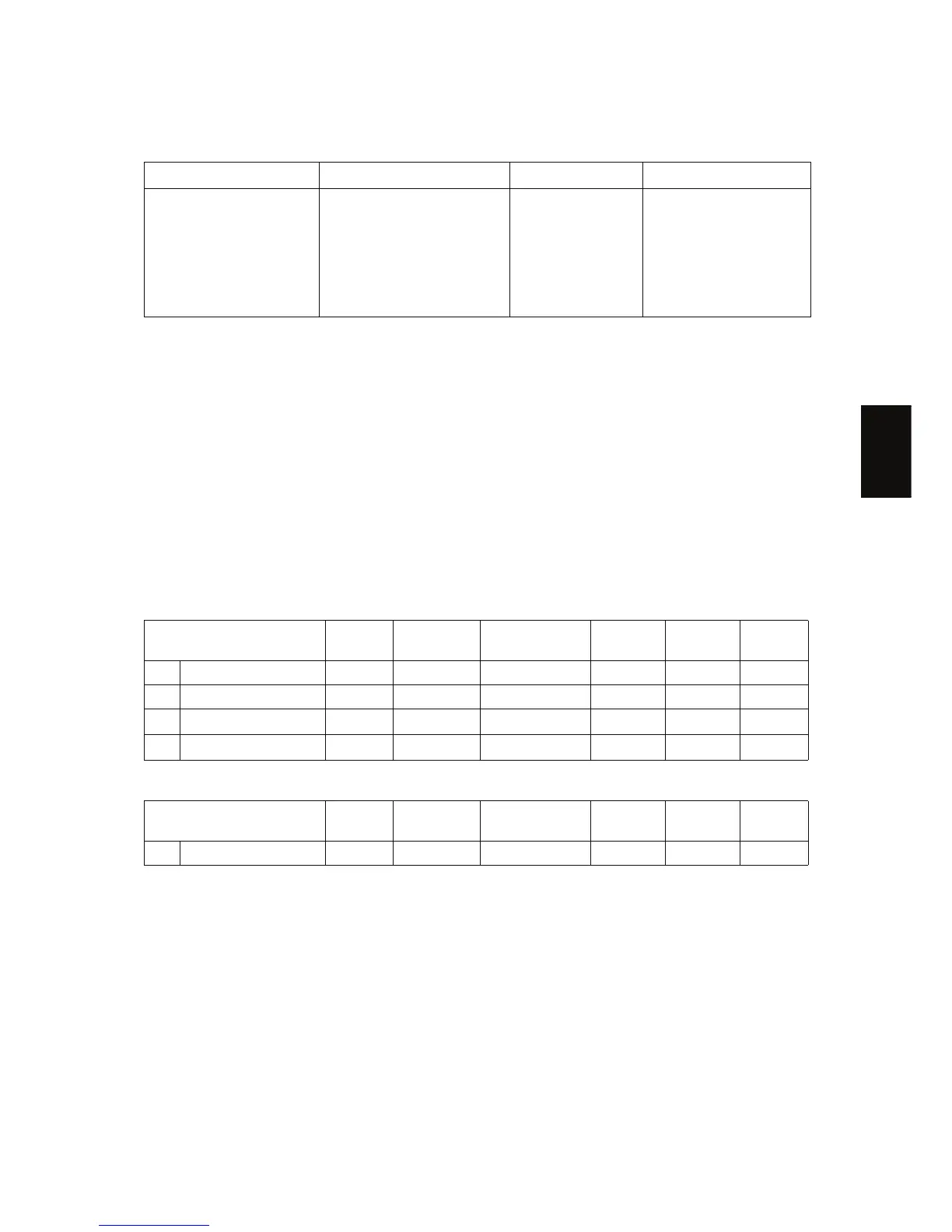

Cleaning Lubrication/Coating Replacement Operation check

A: Clean with alcohol

B: Clean with soft pad,

cloth or vacuum

cleaner

L: Launa 40

SI: Silicon oil

W1: White grease

(Molykote X5-6020)

W2: White grease

(Molykote HP-300)

AV: Alvania No.2

FL: Floil (GE-334C)

Value:

Replacement

cycle

(Value x 1000)

R:Replace if

deformed or

damaged

O: After cleaning or

replacement, confirm

there is no problem.

Items to check Cleaning Lubrication

Replacement

(x 1,000 sheets)

Operation

check

Parts list

<P-I>

Remarks

A1 Original glass B or A P17-I1 *a1

A2 ADF original glass B P17-I2 *a1

A3 Carriage rail B

A4 Original glass guide B R

P9-I9

Items to check Cleaning Lubrication

Replacement

(x 1,000 sheets)

Operation

check

Parts list

<P-I>

Remarks

B1 Slit glass B

06/04

Loading...

Loading...