E6581386

M-1

13

13.

Before making a service call

- Trip information and remedies

13.1 Trip causes/warnings and remedies

When a problem arises, diagnose it in accordance with the following table.

If it is found that replacement of parts is required or the problem cannot be solved by any remedy described in the table,

contact your supplier.

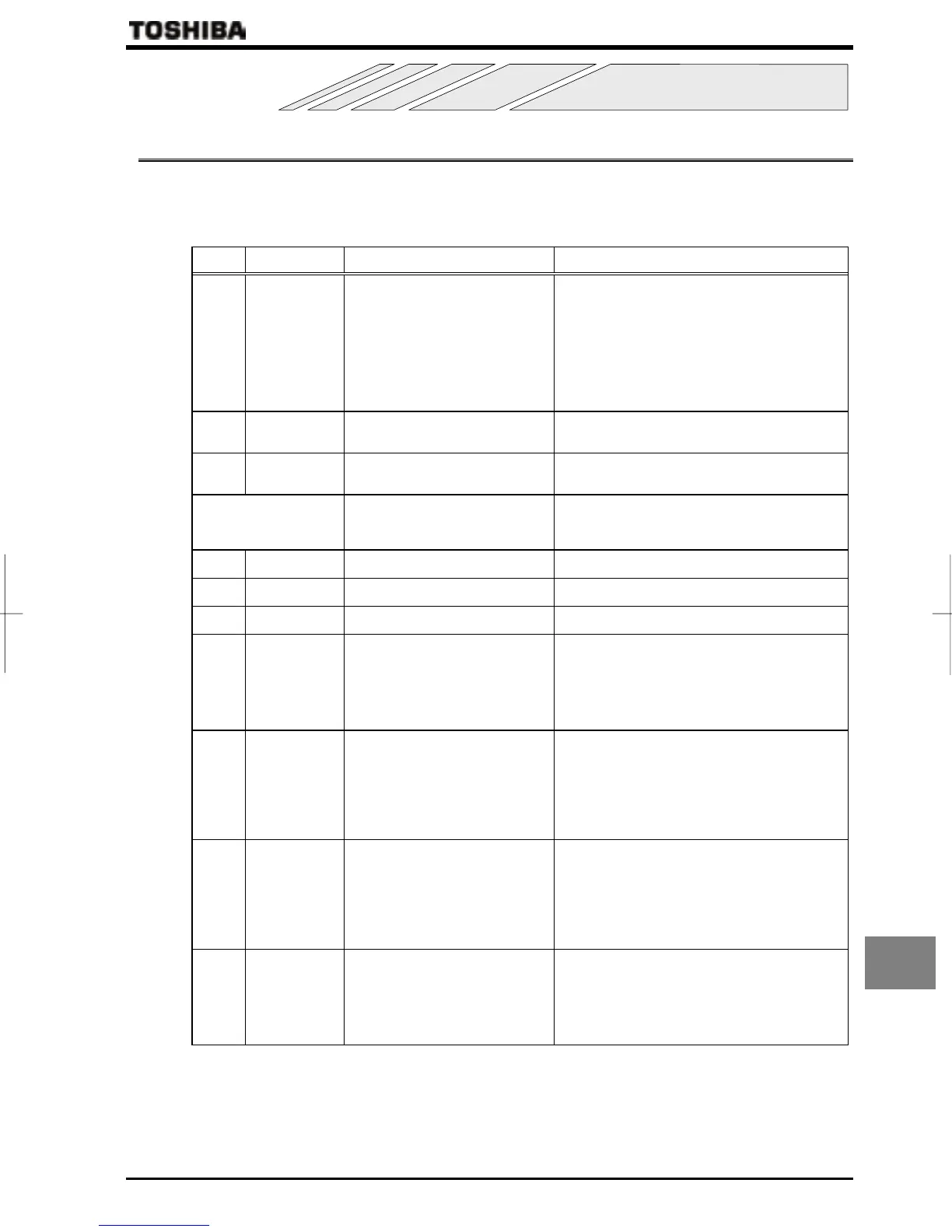

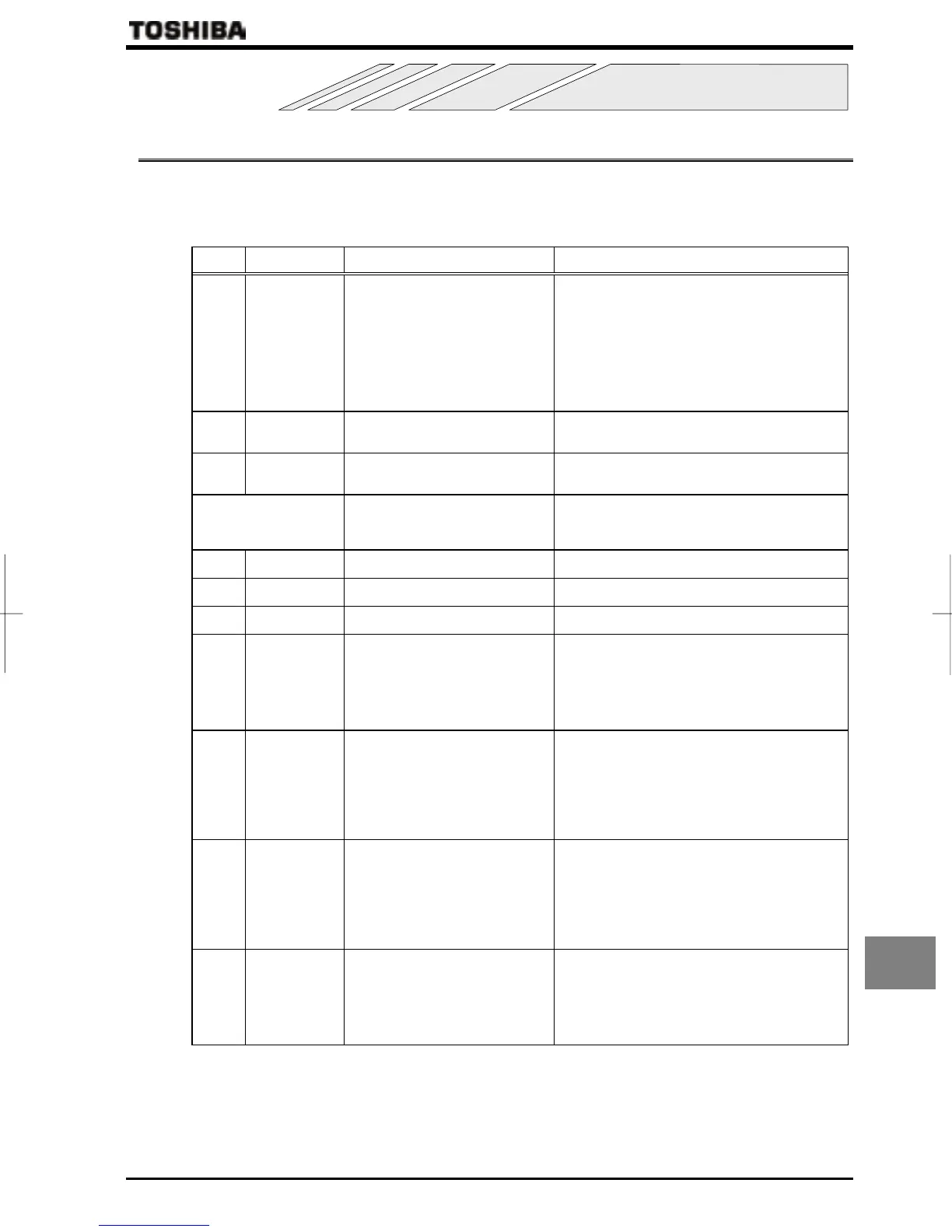

[Trip information]

Error

code

Description Possible causes Remedies

*

Overcurrent

during

acceleration

•

The acceleration time

is too short.

•The V/f setting is improper.

•A restart signal is input to the

rotating motor after a momentary

stop, etc.

•A special motor (e.g. motor with a

small impedance) is used.

•

Manual torque boost value

is lar

e.

•Increase the acceleration time .

•Check the V/f parameter setting.

•Use (Auto-restart) and (Regenerative

power ride-though control).

•Increase the carrier frequency .

•Decrease setting value.

•Decrease

stall prevention level

to 130 as

a guide.

•Increase (carrier frequency) setting value if it

is set at lower value (2kHz or less).

*

Overcurrent

during

deceleration

•The deceleration time is too

short. (in deceleration)

•Increase the deceleration time .

*

Overcurrent

during fixed

speed

•The load fluctuates abruptly.

•The load is in an abnormal

condition.

•Reduce the load fluctuation.

•Check the load (operated machine).

[Note] , ,

originate from

causes other than those

mentioned above.

•

A main circuit elements is defective.

•Overheat protection is activated.

•Make a service call.

•Check operation of cooling fan.

•Check cooling fan control mode parameter

.

*

U-phase

arm

short-circuit

•A main circuit elements is defective

(U-phase).

•Make a service call.

*

V-phase

arm

short-circuit

•A main circuit elements is defective

(V-phase).

•Make a service call.

*

W-phase

arm

short-circuit

•A main circuit elements is defective

(W-phase).

•Make a service call.

Loaded side

overcurrent at

start time

•The insulation of the output main

circuit or motor is defective.

•The motor has too small

impedance.

•The drive circuit board in the

inverter was damaged.

•Check the cables and wires for defective

insulation.

•Selection of short circuit detection at starting

parameter .

•If this error message appears when a motor is not

connected to the inverter, the inverter itself ma

be

faulty, so make a service call.

D

namic brakin

element

overcurrent

(200V-55kW or

larger, 400V-

90kW or lar

er

•PB-PC/+ circuit is shorted.

•A resistor with resistance smaller

than the minimum allowable

resistance is connected.

•Parameter was set to or

without connecting regenerative

brake or with wire disconnected

(with dynamic braking).

•Check the impedance wirin

for the resistor, etc.

•Make a service call.

•Check if regenerative brake is connected.

•If regenerative brake is not necessary, set

parameter to .

Overheating

•The cooling fan does not rotate.

•The ambient temperature is too

high.

•The vent is blocked up.

•A heat generating device is

installed close to the inverter.

•The thermistor in the unit is

disconnected.

•Restart the operation b

resettin

the inverter afte

it has cooled down enough.

•The fan requires replacement if it does not rotate

during operation.

•Secure sufficient space around the inverter.

•Do not place any heat generating device near the

inverter.

•Make a service call.

Thermal trip

stop command

from external

device

•An input signal is impressed at

control input terminal PTG for

optional add-on cards.

•A thermal trip command (input

terminal function: or ) is

issued by an external control

device.

•The motor is overheated, so check whether the

current flowing into the motor exceeds the rated

current.

* In the event one of the error codes to and to appears, in which case a main circuit

component has most probably failed, the only way to reset the inverter is to turn power off and back on.

(Continued overleaf)

Loading...

Loading...