Installation

28 RT-SVX21AC-EN

Supply and return air openings as viewed from a

downflow configuration are shown in the following

drawings.

Elbows with turning vanes or splitters are recommended

to

minimize air noise due to turbulence and to reduce s

tatic

pressure.

When attaching the ductwork

to the unit, provide a water

tight flexible con

nector at the unit to prevent operating

sounds from transmitting through the ductwork.

All outdoor ductwork between the unit and the

structure

should be weather proofed after installation is completed.

Roof Curb

Downflow

The roof curbs for these units consists of a “full perimeter”

enclosure to support the unit just inside of the unit base

rail. The 10 ton high efficiency units contain a support base

alignment rail and will extend past the end of the roof curb

as shown in figures below.

Before installing any roof curb, verify;

• It is the correct curb for the

unit,

• It includes the necessary gaskets and h

ardware,

• The installation location provides the required

clearance fo

r proper operation,

• The curb is level and square. The top surface of the

curb must be true to assure an adequate curb-to-unit

seal.

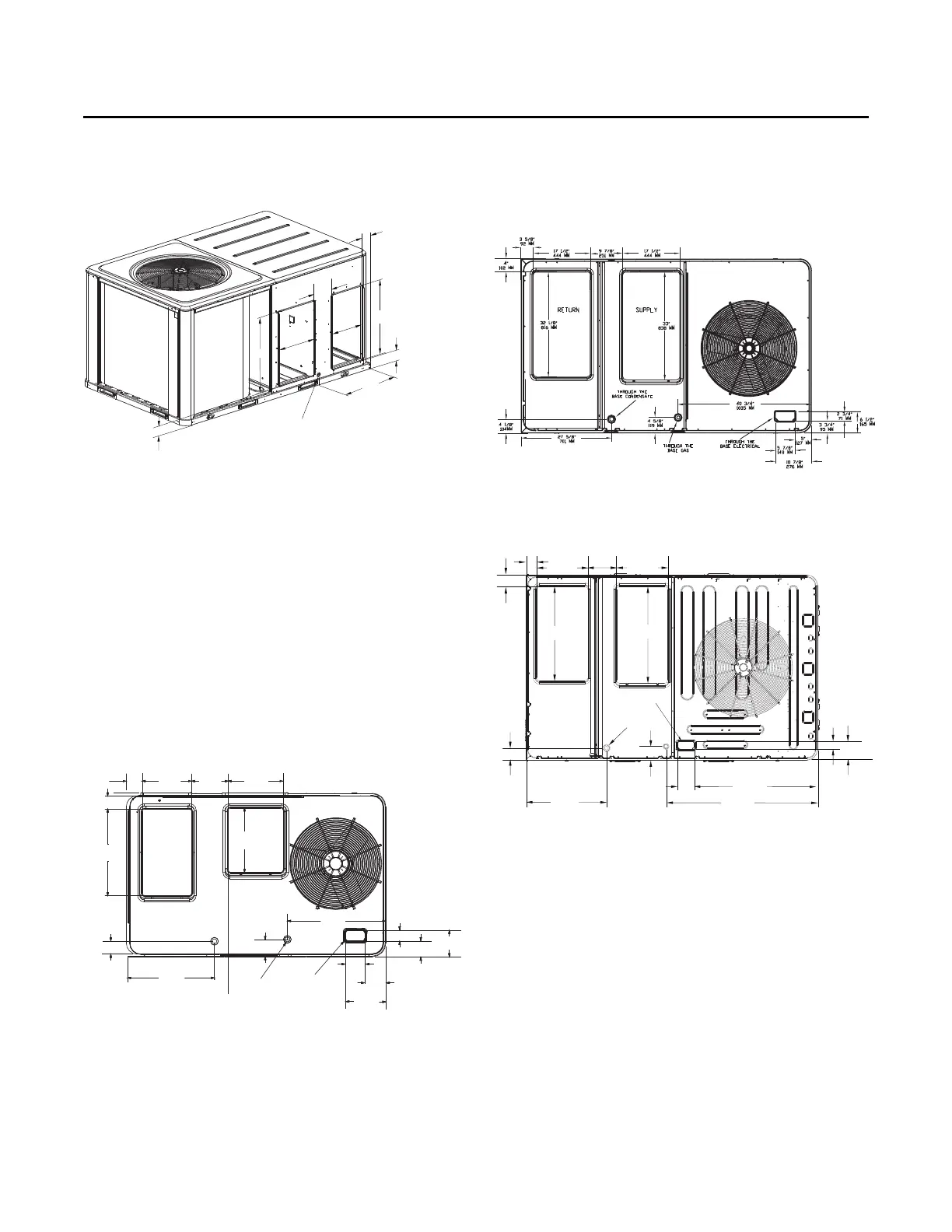

Fi

gure 34. Cooling and gas/electric —10 tons high

effic

iency— horizon

tal airflow, supply and

return

(a)

(a) All dimensions are in inches/millimeters.

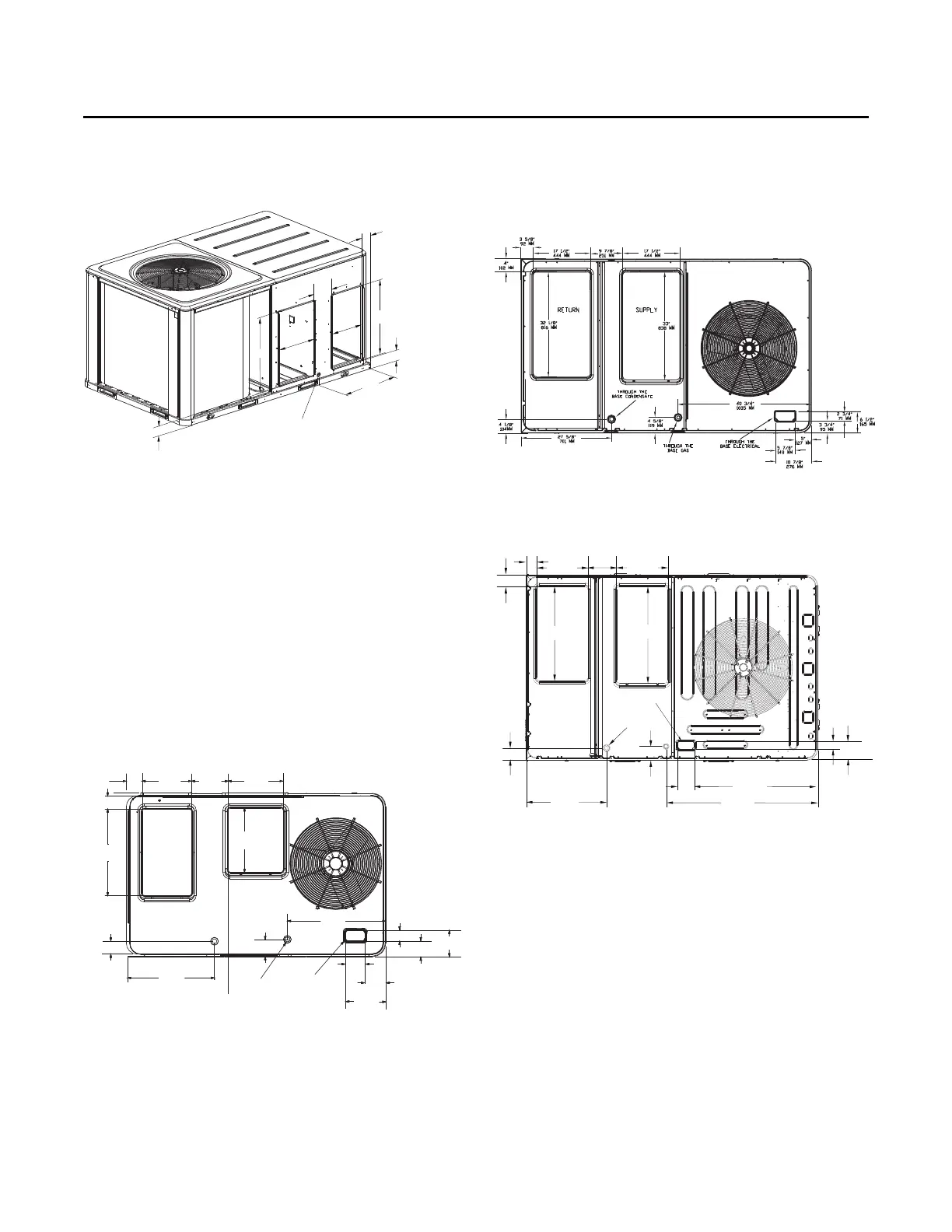

Figure 35. 3 to 5 ton standard efficiency units and 3 ton

high efficiency units - downflow supply and

return air openings w/ through-the-base

utilities

4 1/4”

108 MM

32 1/4”

832 MM

19 1/4”

489 MM

SUPPLY

RETURN

16 3/4”

425 MM

9 3/8”

238 MM

32 1/4”

832 MM

4 3/4”

120 MM

27 5/8”

701 MM

3/4 - 14 NPT DIA. HOLE

CONDENSATE DRAIN

3 7/8”

98 MM

THROUGH

THE BASE GAS

THROUGH

THE BASE

ELECTRICAL

SUPPLY

RETURN

TBU CONDENSATE

3 5/8”

92 MM

14”

356 MM

9 1/4”

235 MM

15 1/2”

394 MM

4”

102 MM

24”

610 MM

18”

457 MM

27 9/16”

701 MM

4 3/16”

106 MM

4 9/16”

116 MM

23 1/2”

597 MM

2 13/16”

71 MM

6 1/2”

165 MM

3 11/16”

94 MM

4 7/8”

124 MM

5 1/16”

128 MM

9 15/16”

253 MM

Figure 36. 4 to 6 ton high efficiency units, 6(074)-8.5

(Microchannel) high efficiency units and 6 to 10

ton standard efficiency units - down flow

supply and return air openings w/ through-

the- base utilities

Figure 37. 10 ton high efficiency unit - downflow supply

and return air openings w/ through-the-base

utilities

Supply

Return

32 1/8”

816 MM

33”

MM

4”

102 MM

17 1/2”

444 MM

17 1/2”

444 MM

3 5/8”

92 MM

9 7/8”

251 MM

4 1/8”

104 MM

27 5/8”

701 MM

THROUGH THE

BASE CONDENSATE

4 5/8”

119 MM

THROUGH THE

BASE ELECTRICAL

51 13/16”

1316 MM

42 3/16”

1072 MM

5 7/8”

149 MM

6 3/8”

163 MM

2 3/4”

71 MM

Loading...

Loading...