Sequence of Operation

64 RT-SVX21AC-EN

voltage. Adjust potentiometer until output voltage

across TP1 and ground achieves desired CFM setpoint.

2. To increase voltage/CFM, turn potentiometer

clockw

ise.

3. To d

ecrease voltage/CFM, turn potentiometer counter-

clockwise.

Note: With ID fan access panel removed, fan will operate

at lower RPM due to the decrease in pressure. Once

panel is installed, RPM will increase.

17 Plus units with the constant CFM direct

drive indoor fan

Proper airflow is critical to unit operation. All 17 Plus

Precedent units (037, 047, and 067 units) use an indoor fan

that provides a constant CFM. There are two different

types of 17 Plus Precedent units: Single Zone VAV units

and Multi Speed units. Both types of units use the same

type of indoor motor and the same airflow adjustment

procedure.

To adjust airflow on a 17 Plus unit the Service Test mode

must

be used for accurate results. Additionally, airflow

adjustments should be made in either “Cool Stage 2" or

any stage of heat because the fan is driven to its maximum

setting during these stages. Only the maximum fan setting

requires adjustment, all other fan speeds follow the

maximum adjustment and do not require any adjustment.

Using the Service Test Guide in Table 16, p. 51, enter the

un

it into either “Cool Stage 2" or any stage of heat by using

either the “Step Test Mode” or “Resistance Test Mode”.

Once the unit is in either “Cool Stage 2" or any stage of

heat, system ai

rflow (CFM) is determined by:

1. In the indoor fan compartment, locate the R136

potent

iometer on the RTOM

circuit board (also

designated “DA COOL - FAN SPD”). Also, locate the

TP1 test pin loop next to the R136 potentiometer.

2. Measure the DC Voltage across the test pin TP1 and

un

it chassis g

round. Compare DC voltage to the CFM

chart shown in Table 23, p. 64. Table 23, p. 64 shows

what DC voltage corresponds to CFM per ton of unit

cooling.

Note: If

1200 cfm is required from a 3 ton unit

(037) the R136 potentiometer should be

a

djusted so that the DC voltage measured

at TP1 to ground reads 1.65 volts DC.

3. To increase the TP1 voltage, turn the R136

potent

iometer clockwise.

4. To

decrease the TP1 voltage, turn the R136

potentiometer counter-clockwise.

Note: Wi

th the

indoor fan access panel remo

ved, the fan

will operate at a lower RPM because static pressure

is reduced with the door open. Once the panel is

returned the RPM of the indoor fan will increase.

Variable Air Volume Applications

(Traditional VAV)

Supply Air Temperature Control - Occupied

Cooling and Heating

The RTRM is designed to maintain a selectable supply air

temperature of 40°F to 90°F with a +/- 3.5°F deadband. In

cooling, if supply air temperature is more than 3.5 degrees

warmer than the selected temperature, a stage of cooling

will be turned “On” (if available). Then if the supply air

temperature is more than 3.5° cooler than the selected

temperature, a stage of cooling will be turned “Off”. At

very low airflows the unit may cycle stages “On” and “Off”

to maintain an average discharge air temperature outside

the 7° deadband. During low load or low airflow conditions

the actual temperature swing of the discharge air will likely

be greater. The RTRM utilizes a proportional and integral

control scheme with the integration occurring when the

supply air temperature is outside the deadband. As long as

the supply air temperature is within the setpoint

deadband, the system is considered to be satisfied and no

staging up or down will occur.

Note: Th

e RTRM is designed to maintain a selectable

supply ai

r temperature of 40°F to 90°F with a +/-

3.5°F deadband. However, to reduce the risk of

evaporator coil freeze-up in Precedent and Voyager

Light Commercial applications, supply air

temperature should not be set below 50° F.

Supply Air Temperature Control with an

Economizer

The economizer is utilized to control the supply air cooling

at +1.5°F around the supply air temperature setpoint range

of 40°F and 90°F providing the outside air conditions are

suitable. To reduce the risk of evaporator coil freeze-up

supply air temperature should not be set below 50° F.

While economizing, the mechanical cooling is disabled

until the economizer dampers have been fully open for

three minutes. If the economizer is disabled due to

unsuitable conditions, the mechanical cooling will cycle as

though the unit had no economizer.

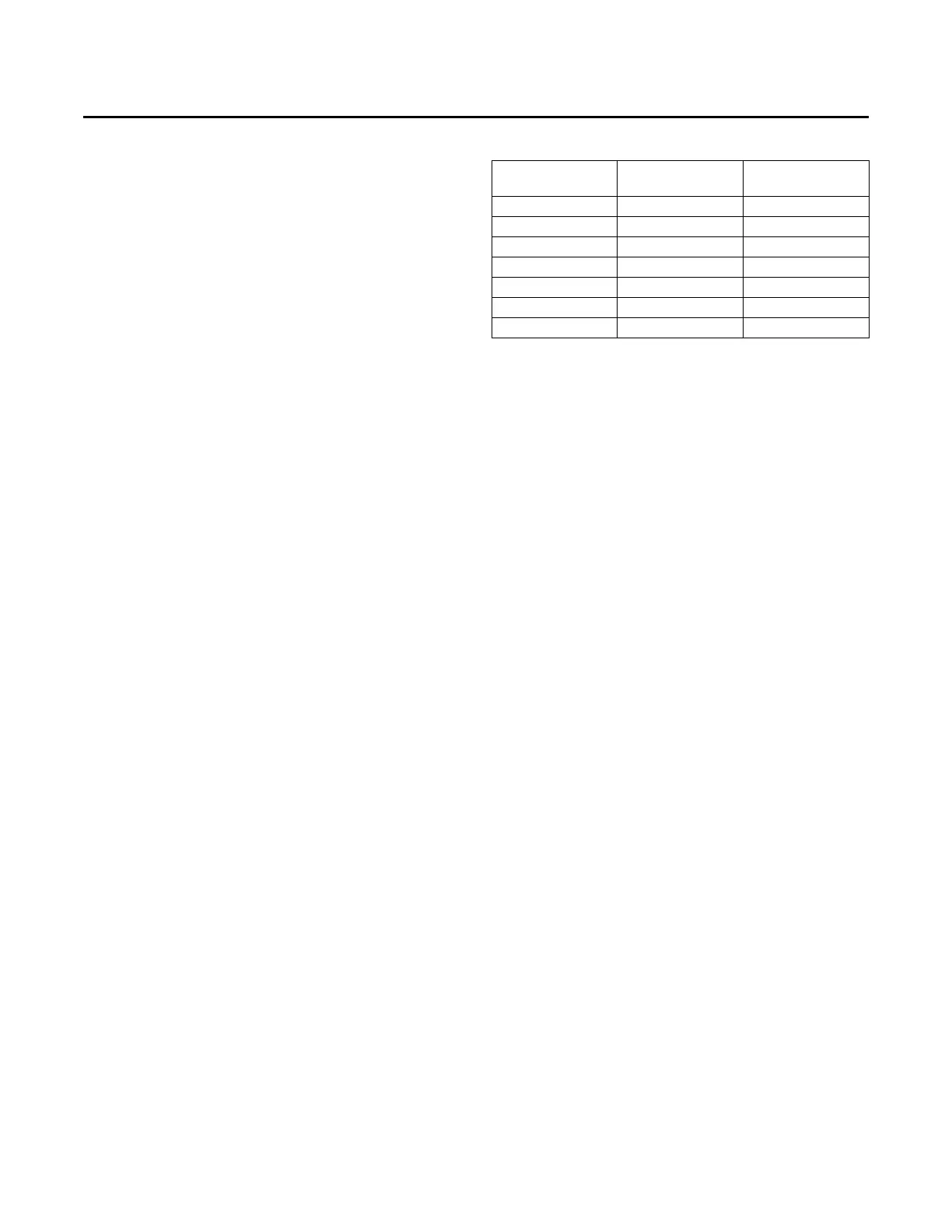

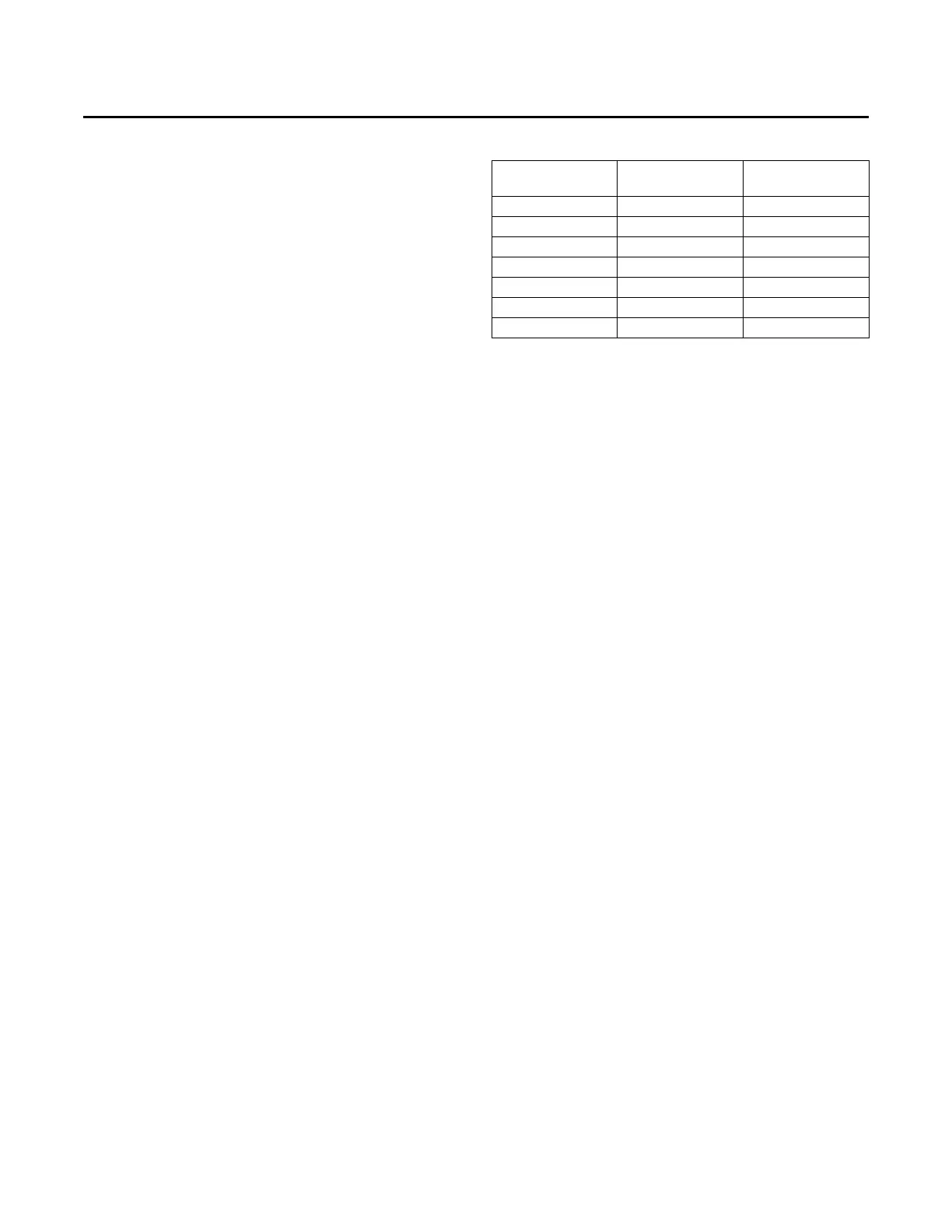

Table 23. Cfm vs. vdc

PWM% value

Potentiometer

Voltage (Vdc) CFM/Ton

70 <0.1 320

75 0.7 347

80 1.25 373

85 1.65 400

90 1.95 427

95 2.17 453

100 >2.4 480

Loading...

Loading...