Sequence of Operation

RT-SVX21AC-EN 61

Drain Pan Condensate Overflow Switch

(Optional)

The condensate overflow switch (COF) is utilized to

prevent water overflow from the drain pan. The float

switch is installed on the corner lip of the drain pan. When

the condensate level reaches the trip point, the COF relay

energizes and opens the 24 Vac control circuit which

disables the unit. Once the 24 Vac control circuit is opened,

a delay timer will prevent unit start-up for three minutes.

Verifying Proper Air Flow

Units with 5-Tap Direct Drive Indoor Fan

Much of the systems performance and reliability is closely

associated with, and dependent upon having the proper

airflow supplied both to the space that is being

conditioned and across the evaporator coil.

The indoor fan motor is factory wired to operate on speed

tap

1 in the coo

ling and heating mode for electric/electric

units. For Gas/Electric units, the motor is factory wired to

operate on speed tap 1 during cooling. For 3 and 4 ton Gas/

Electric units operating in heat mode, the minimum

setting is Tap 4.

For these units, a separate tap terminal is provided to

chan

ge speeds automatically between heating and

cooling. The motor can be rewired for different speed

settings should the application require it. Refer to the

wiring diagram that shipped in the unit and the unit fan

performance tables in the Service Facts.

The indoor fan motors are specifically designed to operate

within the

BHP parameters listed in the fan performance

tables of the unit Service Facts.

When verifying direct drive fan performance, the tables

mu

st be used so

mewhat differently than those of belt

driven fans. Fan performance diagnostics can be easily

recognized when these tables are used correctly.

Before starting the SERVICE T

EST, set the mi

nimum

position setpoint for the economizer to 0 percent using the

setpoint potentiometer located on the Economizer Control

(ECA), if applicable.

ReliaTel™ Control: Using the Service Test Guide in

Table 16, p. 51, momentarily jump across the Test 1 and

Test 2 terminals on LTB1 one time to start the Minimum

Ventilation Test.

Electromechanical Control: Using the Service Test

Guide perform the proper test mode connections.

With the fan operatin

g prop

erly, determine the total

system external static pressure (inches w.c.) by the

following method (ReliaTel™/Electromechanical):

1. Measure the supply and return duct static pressure and

sum the resulting absolute

values,

2. Use the accessory pressure d

rop table

in the Service

Facts, to calculate the total static pressure drop for all

of the accessories installed on the unit; i.e., curb,

economizer, etc.

Note: Acces

sory static pressure drop

is based on desired

CFM and may not be actual static pressure drop.

3. Add the total accessory static pressure drop (step 2) to

the duct extern

al static pressure (step 1). The sum of

these two values represents the total system external

static pressure.

Using the Fan Performance Tables in

the Service

Facts,

look up the selected speed tap setting and match the

measured ESP to determine the approximate CFM.

If the required CFM is too low,

(external static pressure is

hi

gh) do one or both of the following and repeat

procedure:

a. Relieve supply and/or return duct static.

b. Change indoor fan speed tap to a higher value

If the required CFM is too high, (external static p

ressure is

low), do one or both of the following and repeat

procedure:

a. Increase supply and/or

return duct static.

b. Cha

nge indoor fan speed tap to a lower value.

Note: Minimum s

etting for units with

Gas or Electric Heat

is 320 CFM per Ton. For 3 and 4 Ton Gas Heat units

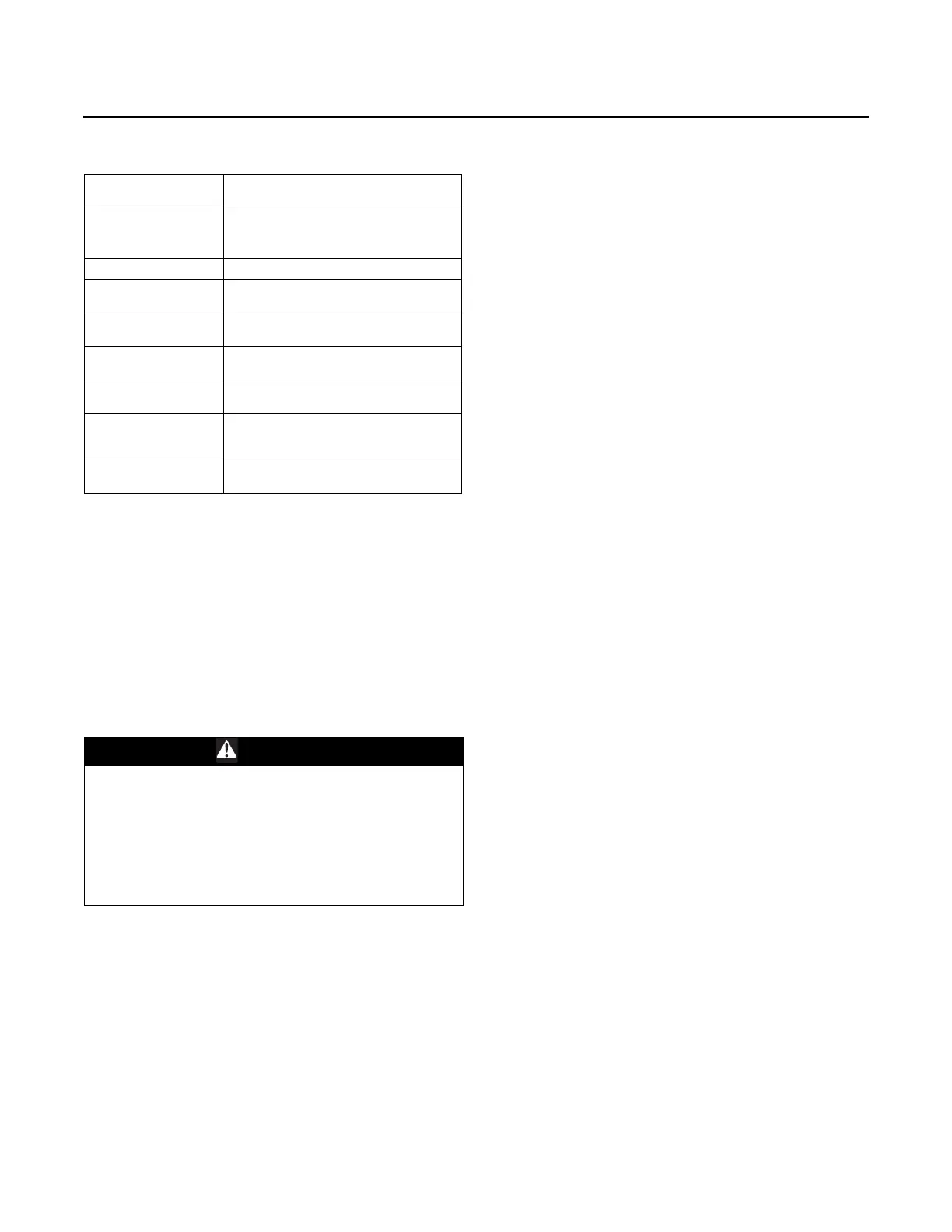

Table 21. Ignition module diagnostics

Steady light

Module is powered up, but no active call for

heat.

Blinking at

continuous steady

rate

Active call for heat.

One blink

Loss of communication.

Two blinks

System lockout (failure to ignite, no spark,

low/no gas pressure, etc.)

Three blinks

Pressure switch (no vent air flow, bad CBM,

closed at initial call for heat). Auto reset.

Four blinks

High limit (excessive heat in combustion

chamber, low airflow). Auto reset.

Five blinks

Flame sensed and gas valve not energized

or flame sensed and no call for heat.

Six blinks

Flame rollout (CBM failure, incorrect gas

pressure, incorrect primary air). Requires

manual reset of the switch.

Seven blinks

W1 and W2 swapped (electromechanical 3-

10 tons units).

WARNING

Live Electrical Components!

Failure to follow all electrical safety precautions when

exposed to live electrical components could result in

death or serious injury. When necessary to work with

live electrical components, have a qualified licensed

electrician or other individual who has been properly

trained in handling live electrical components perform

these tasks.

Loading...

Loading...