Installation

RT-SVX21AC-EN 37

Requirements for Gas Heat

Note: The unit gas train and optional through-the-base

gas shut-off valve are rated at 1/2 PSIG maximum.

A pressure reducing regulator is recommended to

prevent this maximum from being exceeded.

These components must be isolated during field

gas piping test that exceed 1/2 PSIG. It is

recommended that the field piping be capped prior

to the unit gas train or optional through-the-base

gas shut-off valve if present.

• Gas supply line properly sized and connected to the

u

nit ga

s train.

• All gas piping joints properly sealed.

• Gas piping leak checked with

a soap solution. If piping

connections to the unit are complete, do not pressurize

piping in excess of 0.50 psig or 14-inch W.C. to prevent

component failure.

• Drip leg Installed in the gas piping near the unit.

• Minimum gas supply pressure should be

4.5-inch W.C.

• M

aximum gas supply pressure must not exceed 14.0-

inch W.C.

• M

anifold pressure for single stage heaters should be

set

to 3.3-inch W.C.

• Ma

nifold pressure for two stage heaters should

be set

to 3.5-inch W.C. on HIGH FIRE and 1.8-inch W.C. on

LOW FIRE.

Note: Ma

nifold pressure not applicable for units with

Low Nox Gas fur

nace option. Manifold

pressure is not utilized as an adjustment/

checking parameter for this system.

• Flue Exhaust clear of any obstruction.

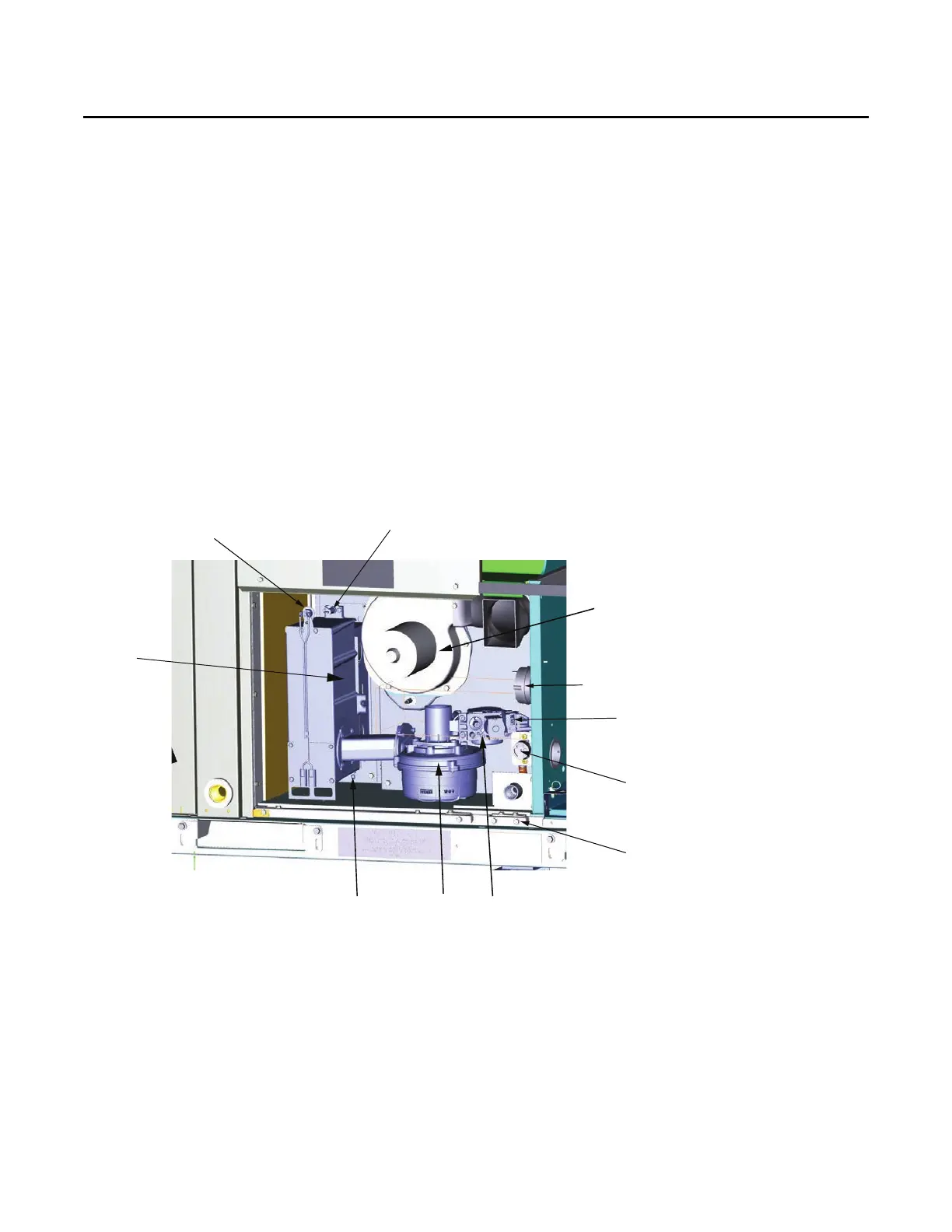

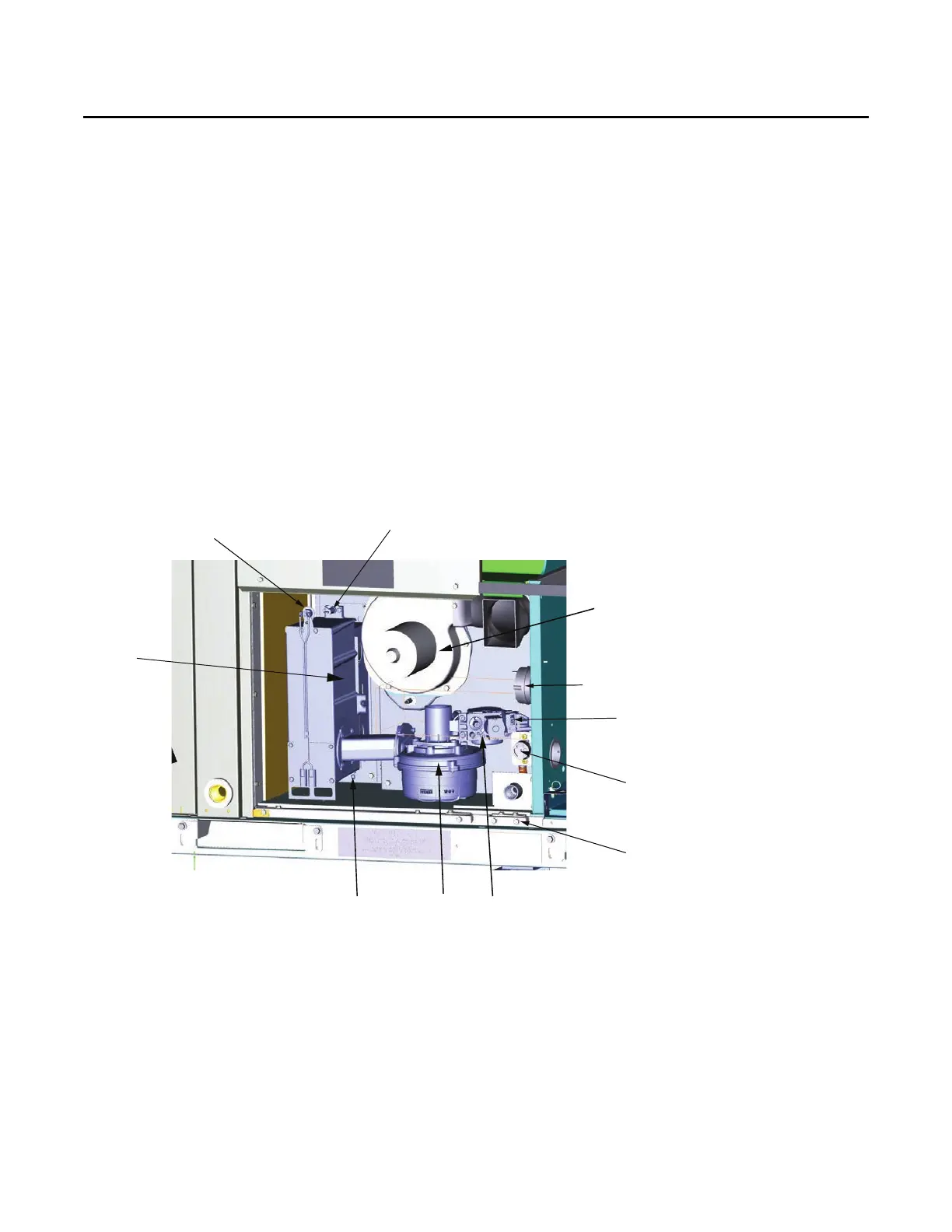

Ultra Low NOx Gas Furnace Option -

Component Layout

Notes:

• The NOx burner assembly is factory set for optimum

performanc

e and should only be adjusted or modified

by a qualified technician.

• The burner box and premix/blower valve are mated

parts - if either part needs replaced the complete

assembly will need to be replaced.

• The low temperature cutoff switch is intended to

prevent gas heat operation below 32F due to low

operating temperature limitations with the premix

blower component.

• The NOx gas furnace option not available for high

altitude

installations above 2000 ft.

Figure 56. NOx burner component layout

Flame sensor (shown for 90k furnace)

Flame rollout switch

Inducer motor

Pressure switch

Gas valve

Premix

blower

Spark

electrode

Note: Illustration is shown without Gas Heat Access Door and Right Center Post.

NOx

burner box

Field connection

- 1/2" npt(f)

Low temperature

ambient cutoff

switch

E box 24V

for gas valve

Loading...

Loading...