Sequence of Operation

RT-SVX21AC-EN 63

Once the supply fan has started, determine the total

system airflow (CFM)

1. Measure the DC voltage across harness test terminals.

Us

ing the fan rpm table shown above, determine RPM

correlated to measured voltage.

2. If the required CFM is too low, (external static pressure

i

s high

causing motor HP output to be below table

value),

a. Relieve supply and/or return duct static.

b. Change indoor fan speed and repeat steps 1 and 2.

• To Increase/Decrease Fan RPM turn DA COOL_FAN

SPD on the RTOM clockwise/counter-clockwise.

3. If the required CFM is too high, (external static

p

ressu

re is low causing motor HP output to be above

table value), change indoor fan speed and repeat steps

1 and 2.

• Stop the SERVICE TEST, turn

the main power

disconnect s

witch to the “Off” position and reconnect

Economizer 4-pin power connector if disconnected for

this procedure.

Proceed to the next component start-up procedure.

Electromechanical Control: Using the Service Test

Guide perform the proper test mode connections.

Once the supply fan

has star

ted, determine the total

system airflow (CFM) by (ReliaTel™/Electromechanical):

1. Measure the amperage at the supply fan contactor and

compare it with the full load amp (FLA) rating

for the

evaporator motor stamped on the unit nameplate.

a. Calculate the theoretical BHP using (Actual Motor

A

mps

/Motor Nameplate Amps) X Motor HP.

b. Using the fan performance tables in the unit Service

Facts, plot the actual RPM (step 1) and the BHP (step

2a) to obtain the operating CFM.

2. If the required CFM is too low, (external static pressure

i

s hi

gh causing motor HP output to be below table

value),

a. Relieve supply and/or return duct static.

b. Change indoor fan speed and repeat steps 1 and 2.

• For ECM board: To Increase/Decrease Fan RPM:

a. Push and hold the SET button for 3 sec.

Board will

disp

lay Motor 1 parameter name: Hi 1.

b. Slow push SET again to display the parameter’s

current

value =7.50 volts.

c. Push on + or – button to adjust parameter

to desired

va

lue = XXX volts.

d. Push and hold SET button for 3 sec to “save” the

value. After sav

e is complete, Hi 1 will show again.

e. After the voltage Hi 1 is successfully changed, the

displa

y sequence will be:

MTR 1---> XXX -----> MTR2 ----->

0.00----->FST1---->ON/

OFF----->FST2------>ON/OFF------->EhEn--

--->ON/OFF

The motor will ramp up or down to adjust to the input

signal. U

sing the fan rpm table above, determine RPM

correlated to displayed voltage.

• If the required CFM is too high, (external static

pre

ssure is low

causing motor HP output to be above

table value), change indoor fan speed and repeat steps

1 and 2.

• To stop the SERVICE TEST, t

urn the m

ain power

disconnect switch to the “Off” position or proceed to

the next component start-up procedure.

Units with Constant CFM Direct Drive

Indoor Fan

Much of the systems performance and reliability is closely

associated with, and dependent upon having the proper

airflow supplied both to the space that is being

conditioned and across the evaporator coil. The indoor fan

provides a constant CFM base on voltage output for the

potentiometer on the RTOM board. Before starting the

SERVICE TEST, set the minimum position setpoint for the

economizer to 0% using the setpoint potentiometer

located on the Economizer Control (ECA), if applicable.

ReliaTel™ Control. Using the Service Test Guide in

Table 16, p. 51, momentarily jump across the Test 1 and

Test 2 terminals on LTB1 one time to start the Minimum

Ventilation Test.

Once the supply fan has started, determine

the total

system airflow (CFM) by:

1

. Measure the DC voltage across pins TP1 and ground

(screw on corner o

f RTOM board). Lookup desired CFM

using the voltage CFM table shown on the access panel

label or in the unit Service Facts; record corresponding

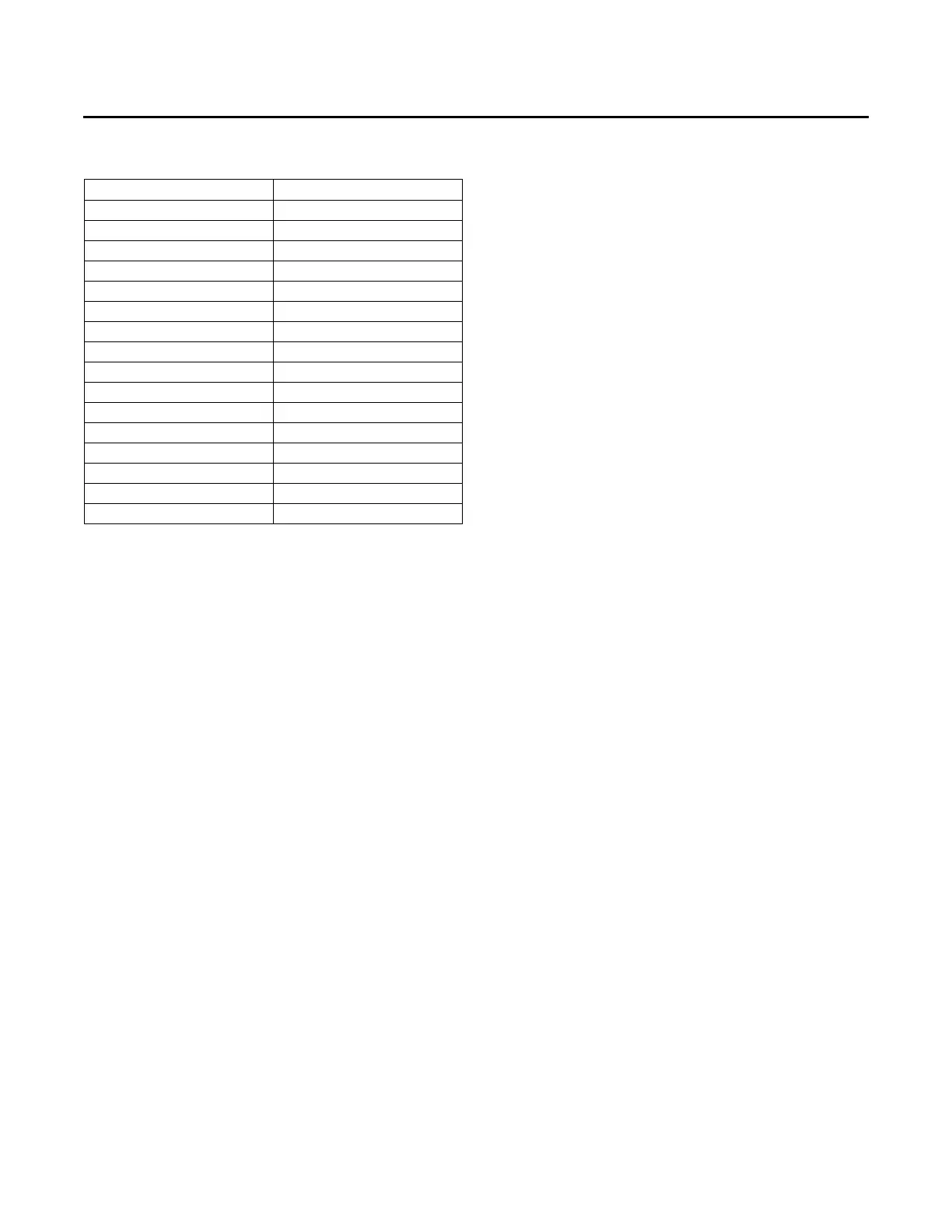

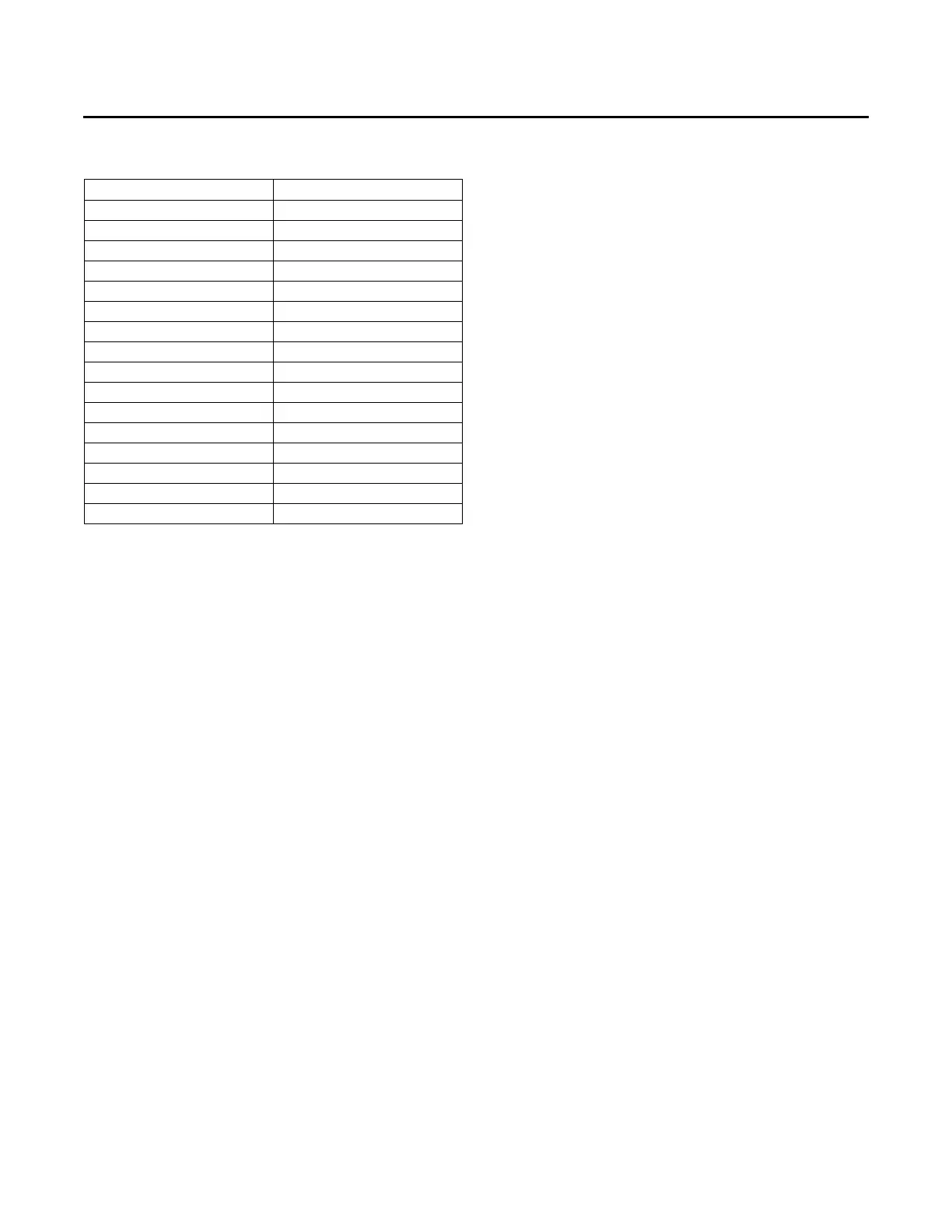

3.75 775

4 845

4.25 912

4.5 976

4.75 1044

5 1115

5.25 1203

5.5 1253

5.75 1312

6 1368

6.25 1425

6.5 1475

6.75 1533

7 1581

7.25 1615

7.5 1615

Table 22. Direct drive plenum fan settings (rpm vs.

voltage) (continued)

Potentiometer Voltage Motor RPM

Loading...

Loading...