60

CHAPTER 11

CHAPTER 11 - START-UP PROCEDURES

11.3.4 Check Gas Piping

Check around the unit for gas odor following the proce-

dure outlined in this manual on page 58.

If any gas leaks are found or suspected, shut

the unit down immediately. Use a gas de-

tection device or bubble test to locate the

source of the gas leak and repair at once. Do

not operate the unit until the leak is correct-

ed. Failure to comply with this procedure will

result in substantial property damage, seri-

ous injury, or death.

11.3.5 Verify Flame Pattern and Combustion

1. Check the ame pattern through the observation

port of the heat exchanger. The ame should be

blue and stable. The ame should be over the

length of the burner head.

Combustion testing and adjustments must be

performed by a qualified installer, service agen-

cy or the gas supplier. All combustion mea-

surements must be performed with recently

calibrated equipment (1 year max.) to ensure

proper reading and accuracy.

2. Test for CO2 or O2 and for CO during high ring

rate. The combustion readings must be within the

range listed in Table 4 on page 61. The CO level

must not exceed 100 ppm for natural gas and

150 ppm for propane gas when combustion is

correct. Perform the following procedure to manu-

ally place the burner into high re.

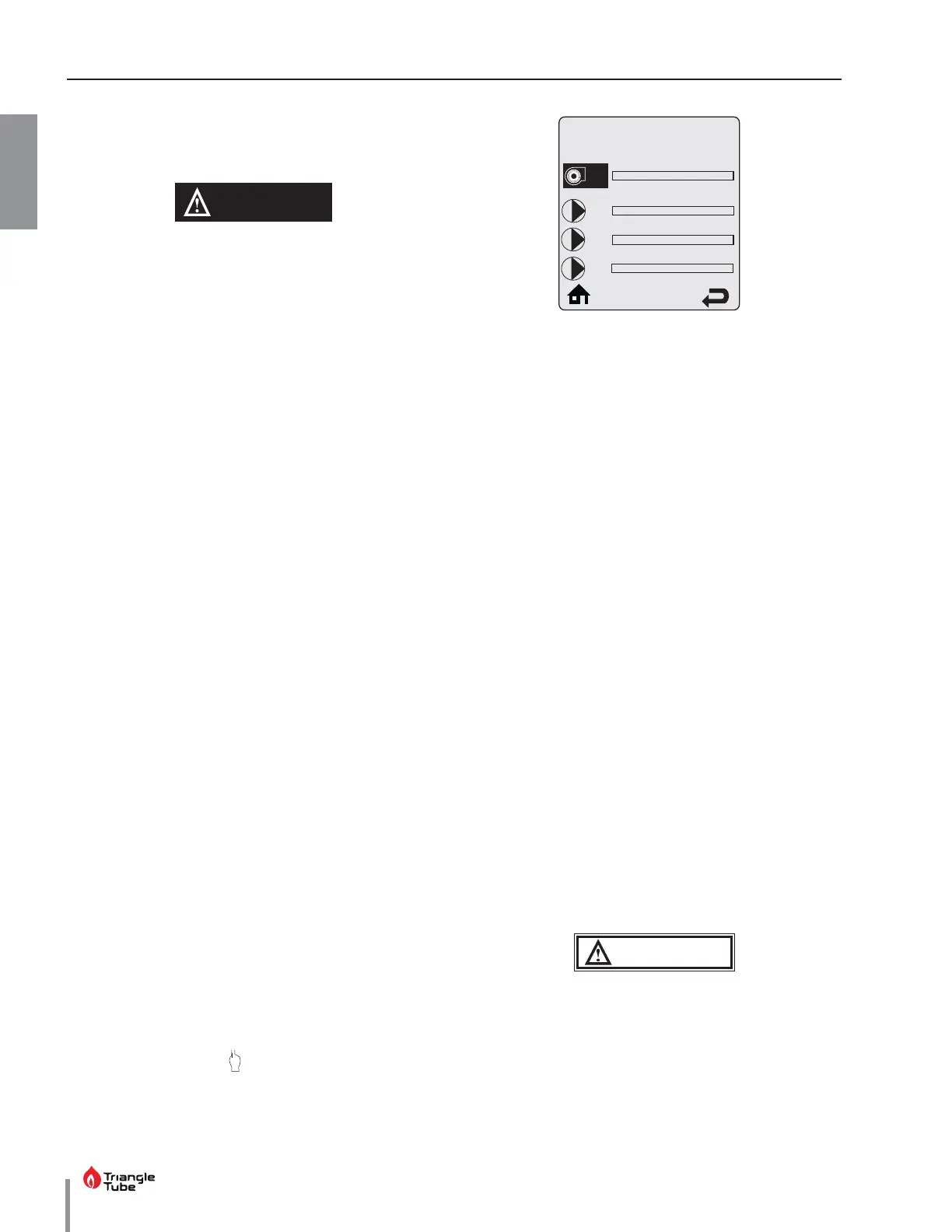

a. Press the round INSTALLER button. Reference

Section 9.1 on page 41.

b. Enter the installer access code “054” by using

the LEFT and RIGHT buttons to select a digit

and the UP and DOWN buttons to change the

digit. Press the OK button to enter the access

code.

c. Press the RIGHT button to highlight the Manual

Operation icon

a

b

c

d

e

f

b

b

b

b

a

b

c

d

e

f

b

b

a

b

c

d

e

a

b

c

d

e

f

b

b

b

b

a

b

c

d

e

f

b

b

a

b

c

d

a

b

c

d

e

f

b

b

b

b

a

b

c

d

e

f

b

b

a

b

c

d

e

a

b

c

d

e

f

b

b

b

b

a

b

c

d

e

f

b

b

f

b

g

a

b

c

d

then press the OK button.

d. Press the OK button while the FAN icon is high-

lighted to manually re the burner and power

the CH circulator(s).

DANGER

NOTICE

An adequate CH load must be present to dissi-

pate the heat generated during the combustion

test. If an adequate CH load is not available, an

indirect water heater can be used to dissipate

the heat by creating a DHW call which will en-

able the DHW circulator.

e. Press the RIGHT button to adjust the ring rate

from 1% to 100%. Hold down the RIGHT but-

ton to rapidly increase the ring rate.

f. Press the OK button while the FAN icon is high-

lighted to shutdown the burner.

3. If the combustion levels during high re (100%) are

outside the acceptable levels, adjust the THROTTLE

SCREW (see Fig. 16, Fig. 17, & Fig. 18 on page 31)

according to Table 3 on page 61.

4. Once the combustion level is set at high re (100%),

manually place the boiler into low re (1%) mode

by pressing the LEFT button to adjust ring rate

down.

5. Verify the combustion levels during low re (1%) are

within the acceptable combustion levels in Table 4

on page 61.

If the combustion levels at low fire (1%) are

not within the range given in Table 4 on page

61, shut the boiler down and contact Trian-

gle Tube Technical Support. Failure to com-

ply with this requirement can result in sub-

stantial property damage, serious injury, or

death.

NOTICE

WARNING

Manual Operation

Released

O

O

O

CH1

FAN

DHW

CH2

Loading...

Loading...