You can use the job for adjusting the X edit when you engrave it in X direction, when

you rotate it by 90° and engrave it in Y direction (which can be done directly in the

manager) you can adjust the Y edits.

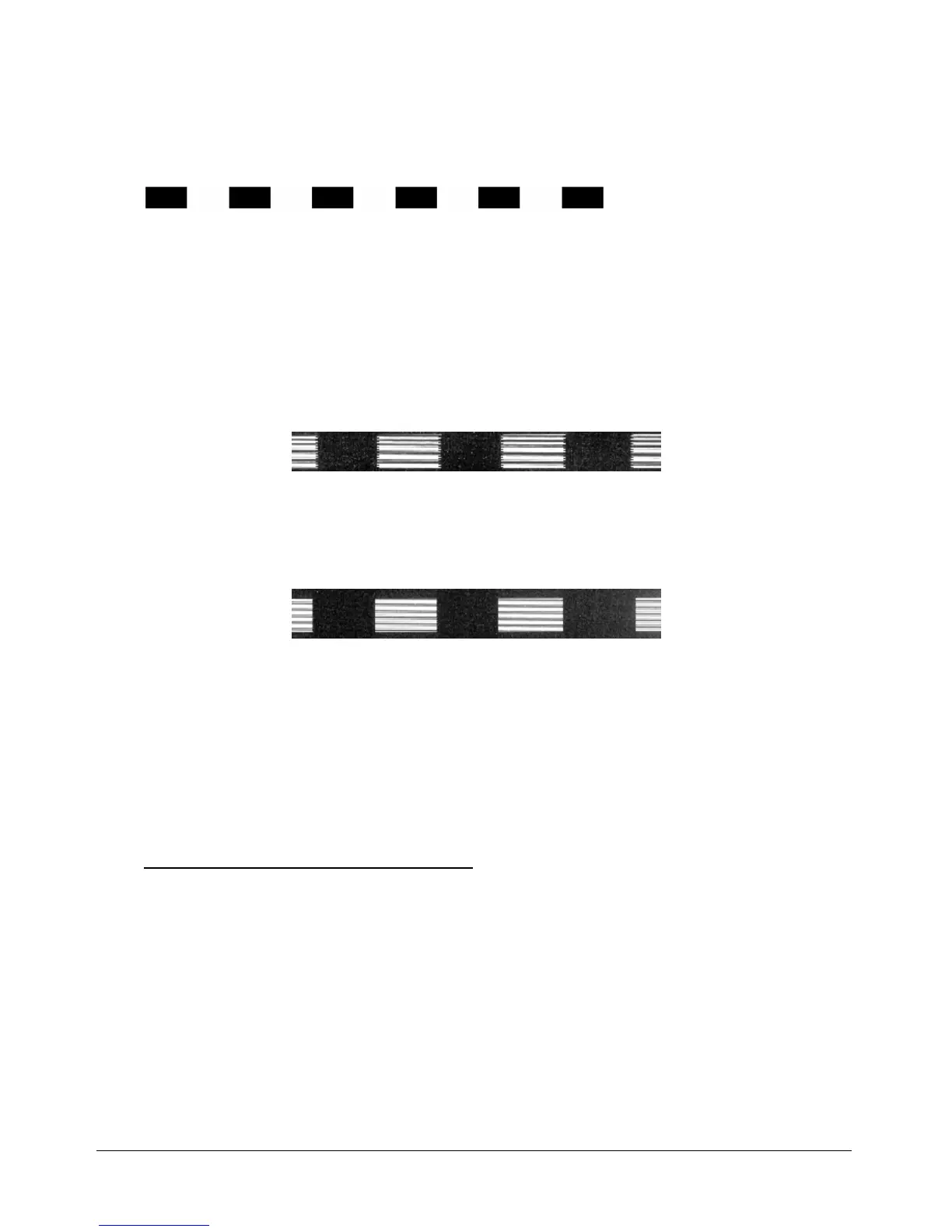

2. In a job like this you can see (when you engrave it) the individual lines (as they

are not overlapping at 125 dpi)

3. Engrave this job at a certain speed and check the shift between the start points of

the lines using a magnifier. (you can see that every line is shifted to the

neighbouring one)

bad adjustment of the edit factor

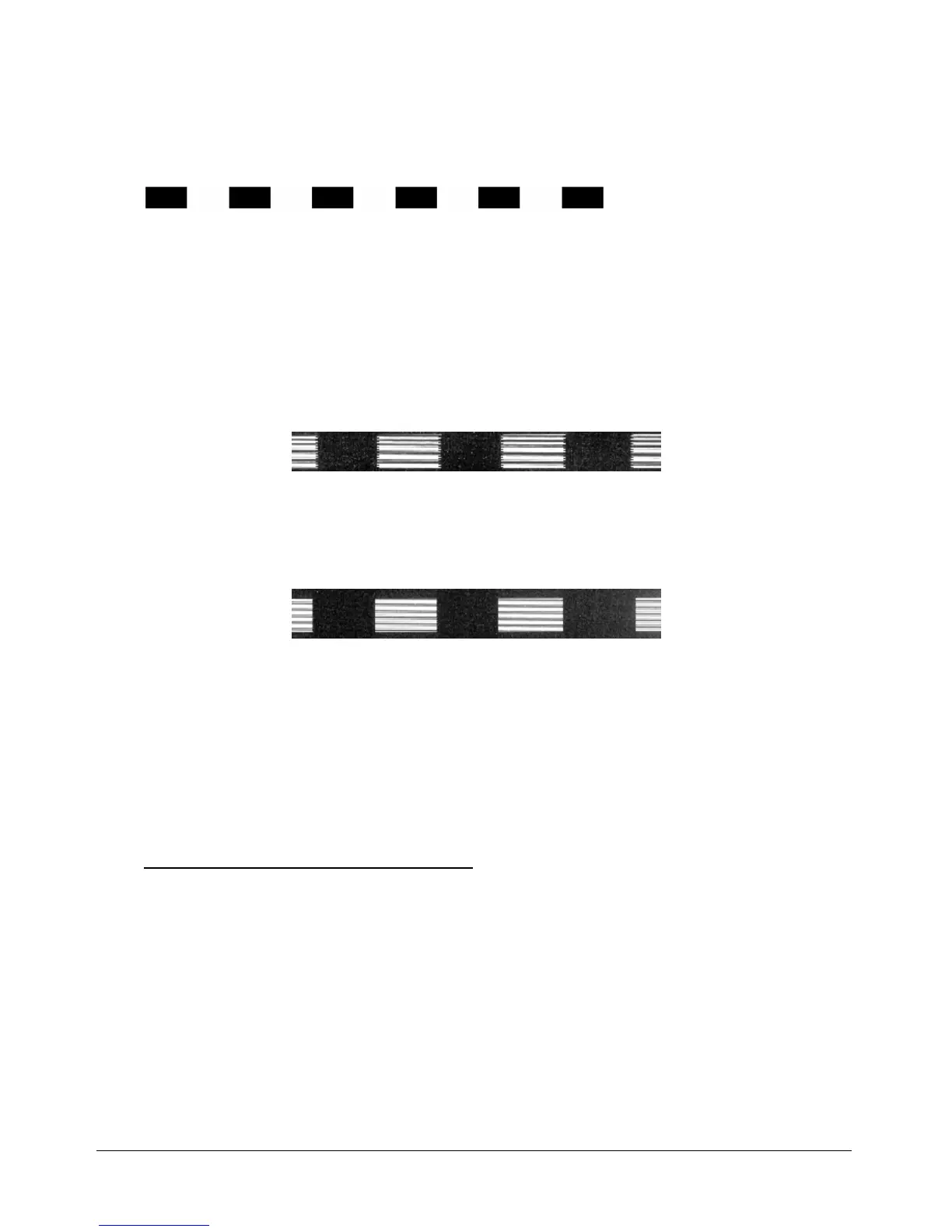

4. A perfectly adjusted machine doesn´t show a shift between the individual start

points.

5. If there is a shift increase or decrease the edit factor and repeat step 3 until it

disappears.

the adjustment is OK now

6. Keep on adjusting until you have at any speed a perfect result.

Note: Before adjusting the Edit factors make sure that tickle power is adjusted

correctly.

To rotate job and engraving direction by 90° go to the plate setup and select the

opposite parameters for engraving direction and job orientation.

Tab „correction“ in the service setup

The default parameters are:

Acceleration: 5

K1: 12

K2: 0

K3: 0

These paramters have been tested well and should never be touched.

Loading...

Loading...