Page 11 of 63 Pages

3. DESCRIPTION OF COMPONENTS

The item numbers refer to the front view in the previous page

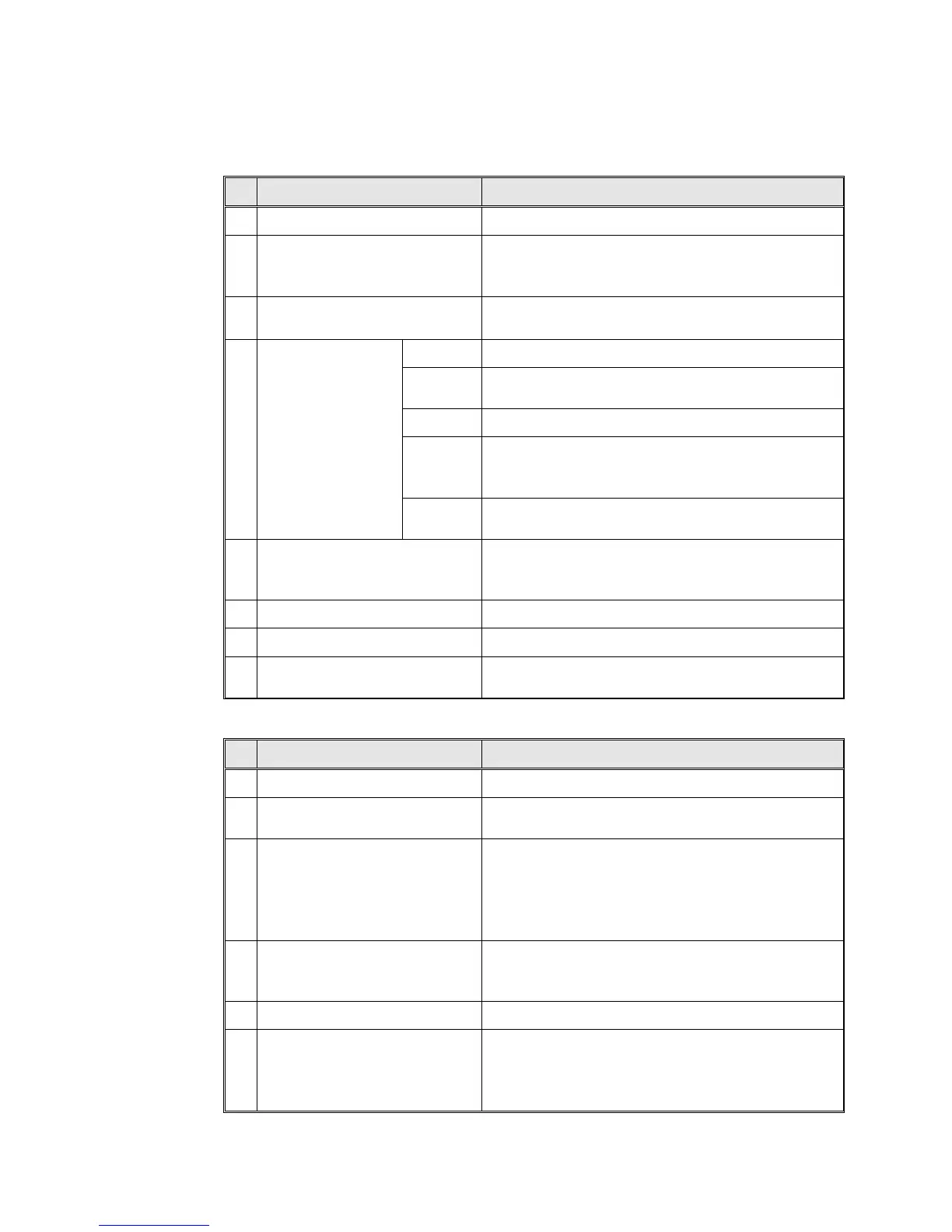

3.1 Control Panel

Item

Description Operation

10.

PRESSURE GAUGE

0-60 psi, (0-4bar) indicates the chamber pressure.

11.

TIMER 0-60 min.

Sets the sterilization and drying cycles and

automatically switches off the power supply to

the heating elements when the times reaches “0”.

12.

PRESSURE SWITCH

Sets the sterilization temperature for each desired

material 221-274ºF, (105-134ºC). See page 18.

Position

1. FILL

Water flows from the water reservoir into the

chamber.

2. STE.

Valve closed to all directions.

3.

XH.&

DRY

Exhausts the steam from the chamber into the

water reservoir after the sterilization cycle is

finished.

13.

MULTI-PURPOSE

VALVE

4. “ 0 ”

Heating elements are disconnected, no cycle is in

progress.

14.

HEAT INDICATOR LIGHT

Lights to indicate that the heaters are activated.

They will shut off when the temperature reaches

the desired value.

15.

DRY INDICATOR LIGHT

Lights to indicate that drying cycle is in process.

16.

POWER INDICATOR LIGHT

Light to indicate that the main switch is on.

17.

MAIN SWITCH-

Main power switch, which supplies electric

power to the autoclave.

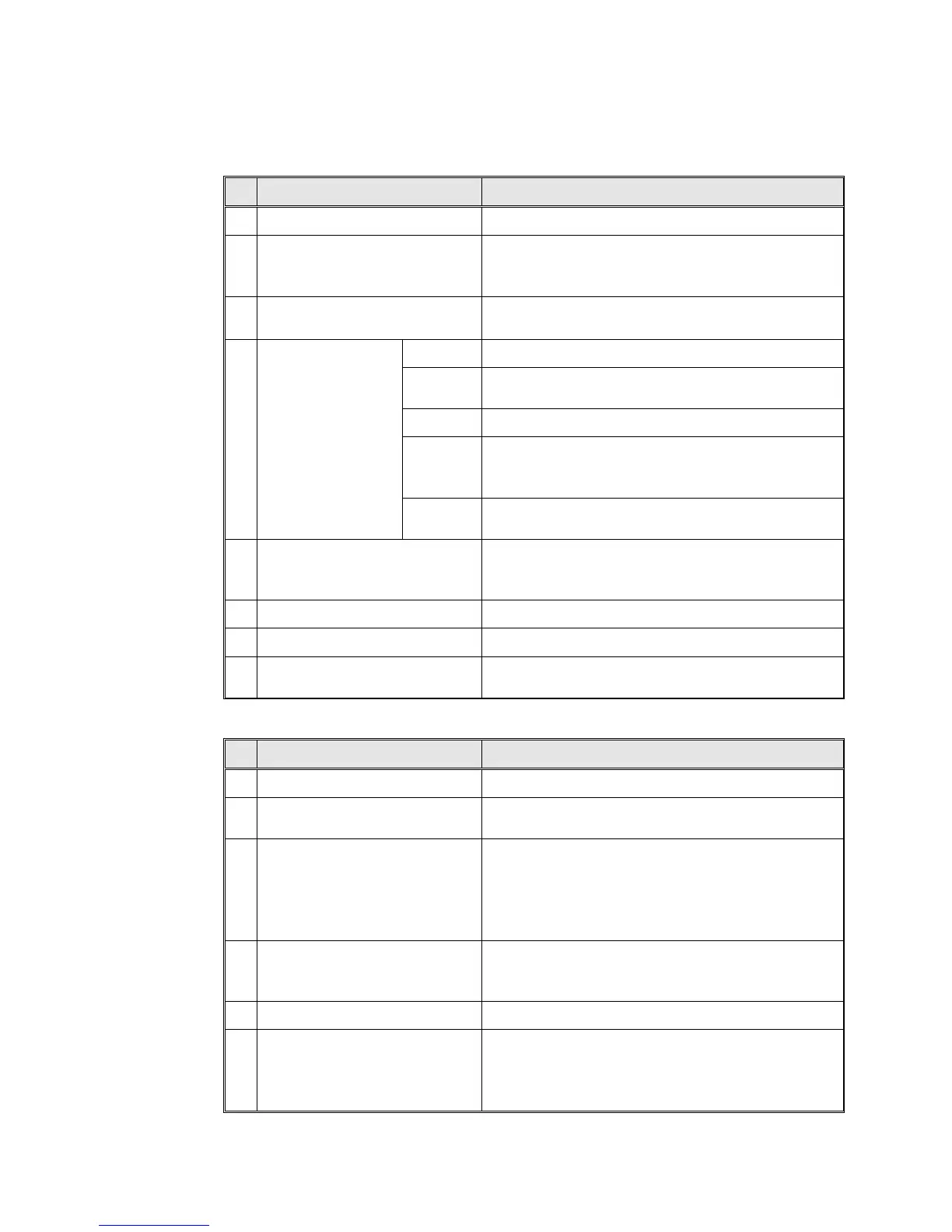

3.2 Other Components

Item

Description Operation

2.

WATER DRAIN VALVE

Enables the drainage of water from the reservoir.

7.

WATER RESERVOIR

Holds ample water for sterilization and also

serves as a steam condenser.

8.

SAFETY VALVE

Blows off when pressure in the chamber reaches

40psi (2.7Bar) in models 1730, 2340, 2540 and

37psi in models 3545, 3850, 3870. This type of

safety valve is A.S.M.E. approved (located in

water reservoir).

9.

AIR TRAP JET

Prevents air pockets in the chamber to ensure

adequate sterilization (located in the water

reservoir).

♦

SAFETY THERMOSTAT

Prevents over-heating during the drying stage.

♦

CUT-OUT THERMOSTAT

Cuts off the power in case of overheating if the

safety thermostat does not operate. This

thermostat does not reconnect automatically but

must be reset.

Loading...

Loading...