- 47 -

7

0

m

m

I

N

D

O

O

R

O

U

T

D

O

O

R

O

U

T

D

O

O

R

S

E

N

S

O

R

R

E

F

R

I

G

E

R

A

N

T

E

L

E

C

T

R

I

C

A

L

D

R

A

I

N

A

G

E

C

A

B

L

E

L

IN

E

S

C

A

B

L

E

T

U

B

E

1

0

m

m

.

M

in

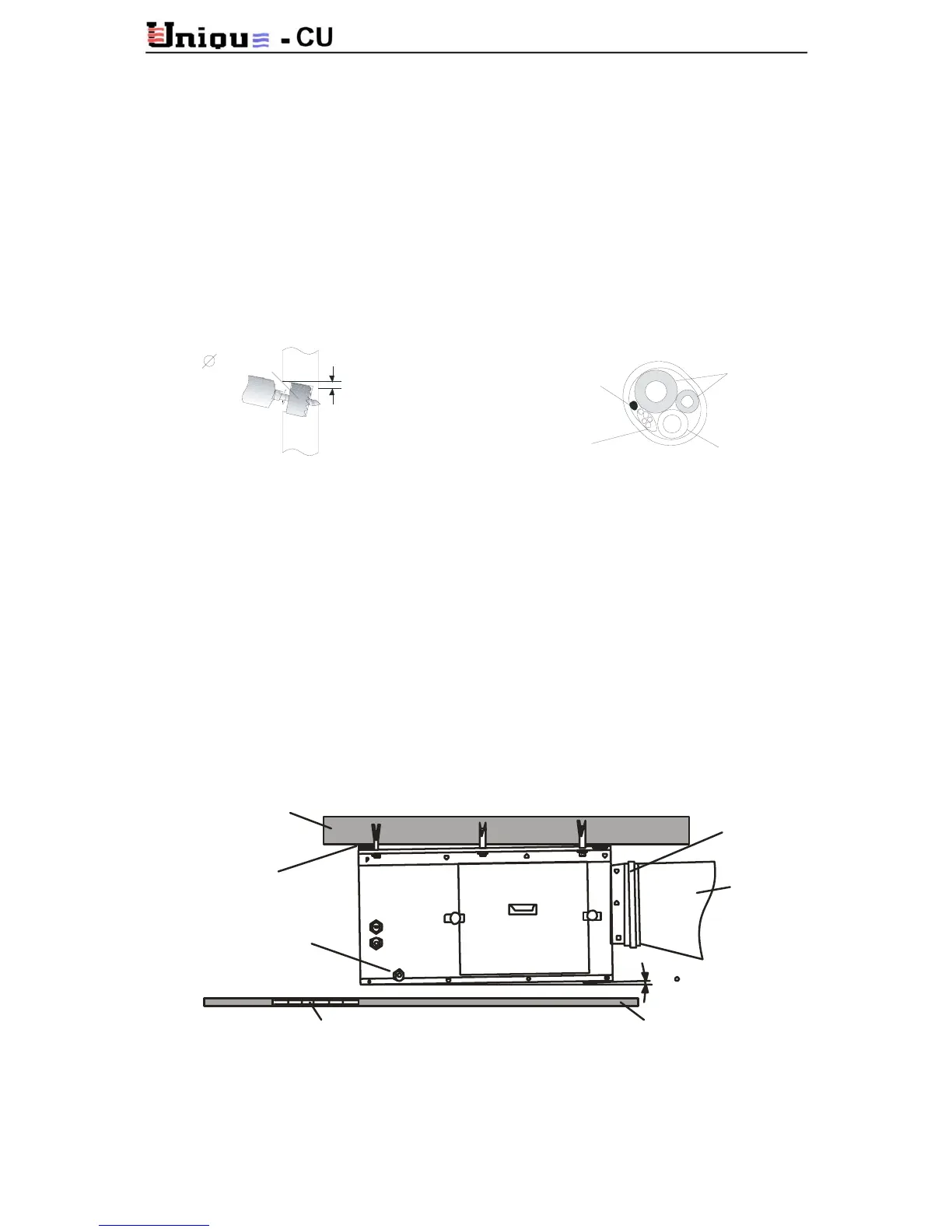

7.6.3 Drilling a Hole in the Wall for Drainage and Inter-Unit Connections

• To make the connections between the indoor and outdoor units, a 70 mm hole should

be drilled for the refrigerant lines, drainage hose and electrical cable passage, through

the wall, as shown in Figure 7-6.

• Make sure to drill outwards and downwards, so that the opening in the outside wall is

at least 10 mm lower than the opening on the inside.

• Route the drainage hose at the bottom of the hole.

• Fill in the remaining gap with an appropriate sealant.

Fig. 7-6

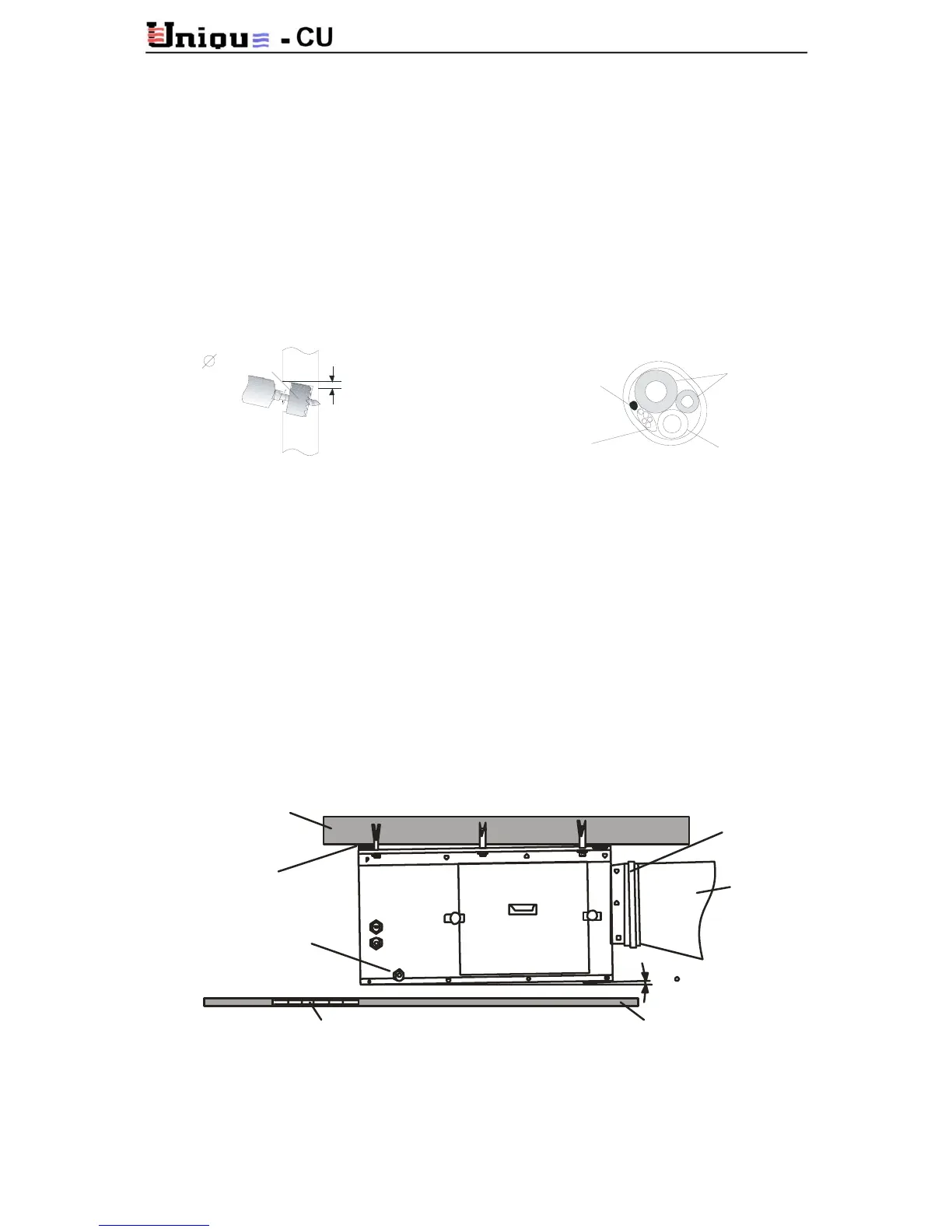

7.7 Air Duct Installation

• The air ducts should be constructed of 0.7-0.8 mm galvanized metal sheet.

• To obtain optimal results, duct cross sections, connections, elbows and branches must

be properly designed. We highly recommend seeking for expert advice on this matter.

• Air ducts should be properly insulated (preferably on the inside) with 50 mm thick

fiberglass insulation having density of at least 24 Kg/m

3

.

• See Figure 7-7 for general guidelines.

Fig. 7-7

CONCRETE

SLEEVE

AIR DUCT

RUBBER

DRAIN HO SE

AIR INTA KE G RILL C EIL IN

Loading...

Loading...