Page 2-7

Operation and Specifications 2.5 - Maintenance

MX15/19

B

Y

T

RUCK

Maneuver the work platform into transport position and chock the wheels. Secure the work plat-

form to the transport vehicle by attaching chains or straps of adequate load capacity to the Tie

Down/Lifting D-Rings.

2.5 M

AINTENANCE

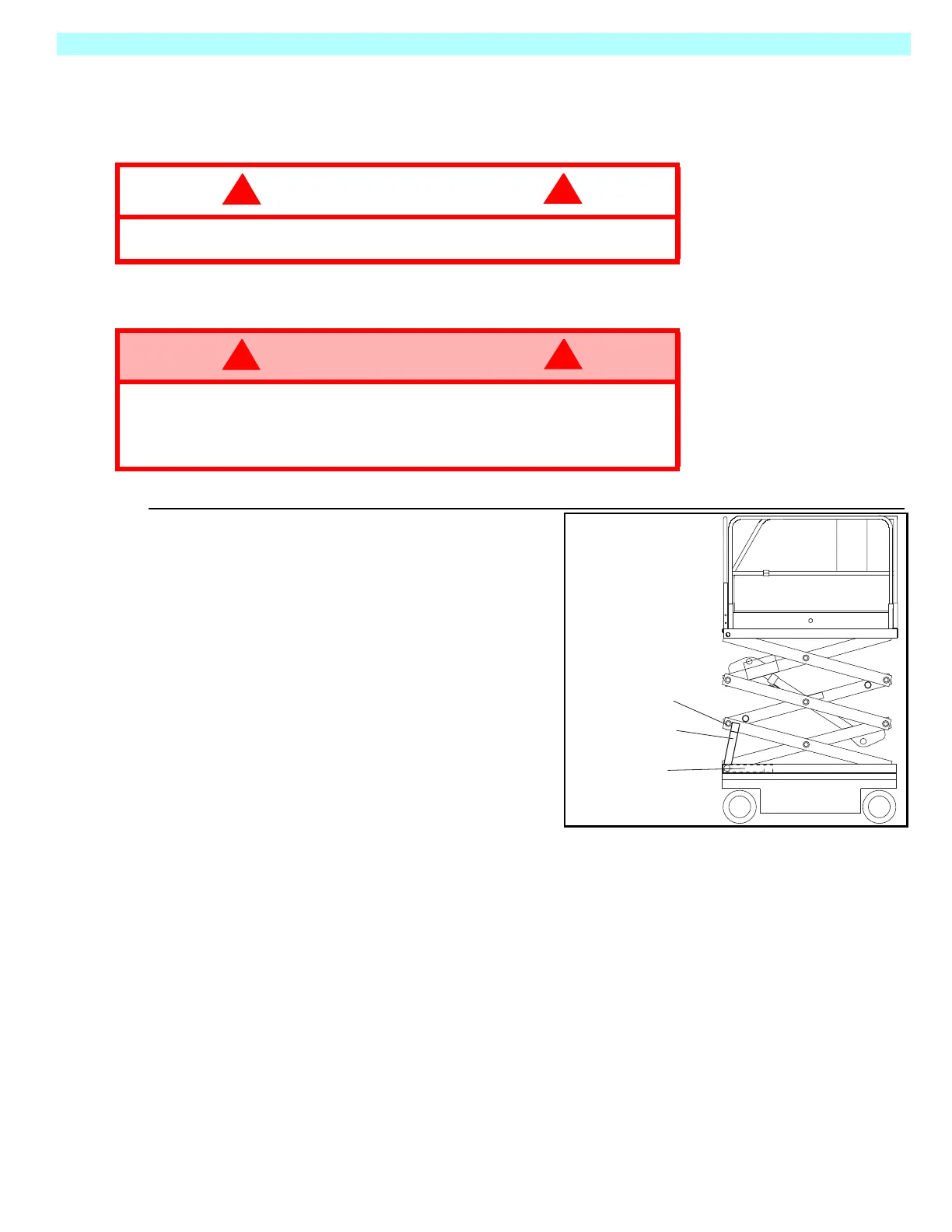

Figure 2-7:

Scissor Brace

B

LOCKING THE

E

LEVATING

A

SSEMBLY

SCISSOR BRACE INSTALLATION

1. Park the work platform on a firm, level

surface. Completely unload the plat-

form before installing the Scissor

Brace.

2. Verify that the Chassis and Platform

Emergency Stop Switches are ON by

pulling each button out.

3. Turn and hold the Chassis Key Switch

to CHASSIS. Push the Chassis Lift/

Lower Switch to UP and elevate the

platform approximately 7 ft. (2.1 m).

4. Rotate the Scissor Brace to a vertical

position.

5. Carefully lower the platform until the end of the Scissor Arm Weldment rests on the Brace.

S

CISSOR

B

RACE

S

TOWAGE

1. While holding the Brace, slowly raise the platform, using the Chassis Controls until the end

of the Scissor Arm Weldment clears the Scissor Brace.

2. Rotate the Scissor Brace forward to rest on the Chassis.

3. Push the Chassis Lift/Lower Switch to LOWER and completely lower the platform.

CAUTION

!

!

Overtightening of the chains or straps attached to the Tie Down/Lifting D-

Rings may result in damage to the work platform.

WARNING

!

!

Never perform service while the platform is elevated without first blocking the

elevating assembly.

DO NOT stand in the elevating assembly area while deploying or storing the

brace.

Brace Installed

Scissor Arm

Weldment

Brace Stowed

Loading...

Loading...