SECTION 9: ILLUSTRATED PARTS LIST AIR N ARC

®

200 SERIES ALL-IN-ONE POWER SYSTEM

®

PAGE - 116 090019-OP_r0

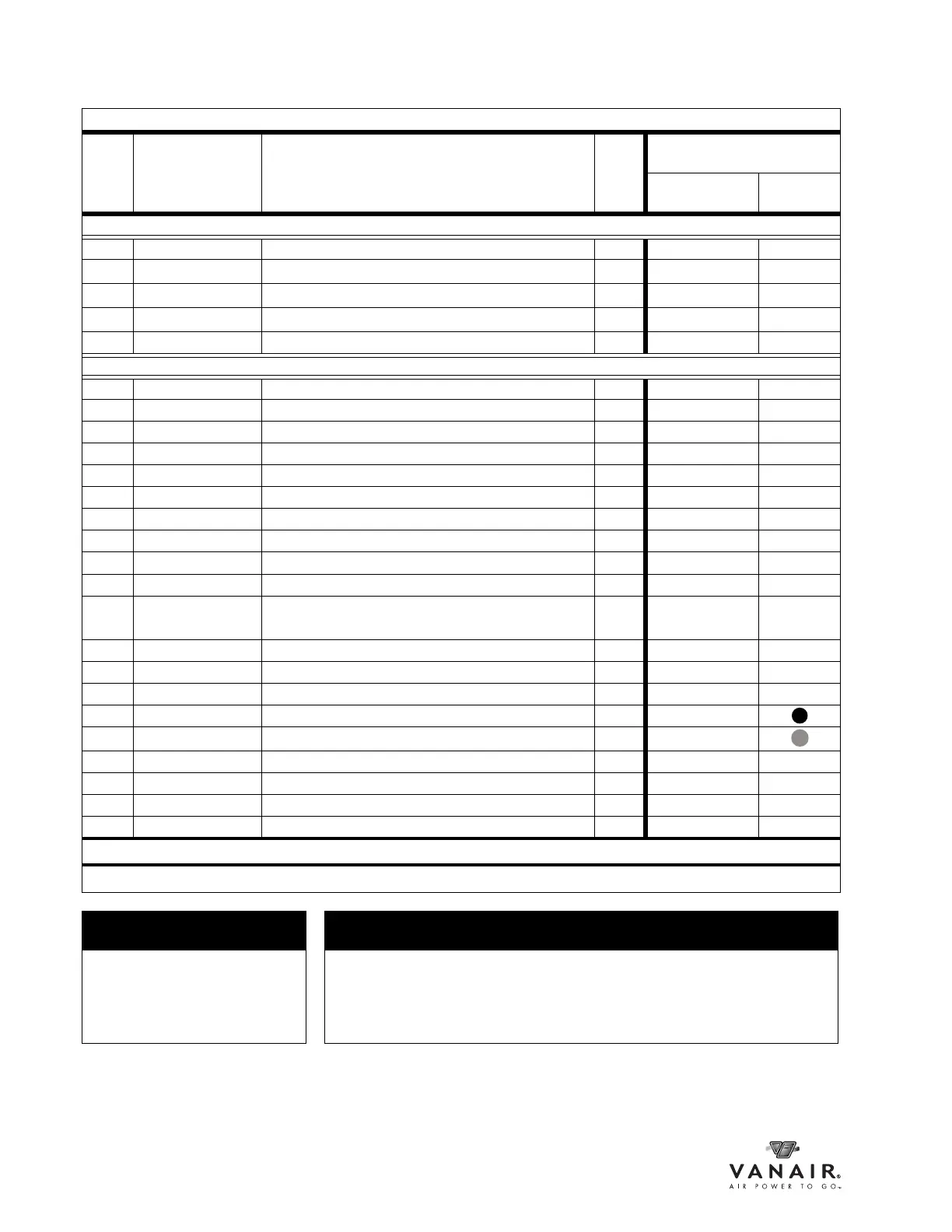

TABLE 9A: RECOMMENDED SPARE PARTS LIST

KEY

NO.

PART

NUMBER

DESCRIPTION QTY IDENTIFICATION

REFERENCE

FIGURE or

SECTION

KEY NO.

ROUTINE/SCHEDULED MAINTENANCE ITEMS

1 RC99245 Element, Compressor Air Filter Assembly 1 Figure 6-1 B

2 262722

Element, Engine Air Filter

I

1 Figure 6-20 G

3 270757

Filter, Engine Oil

I

1 Figure 6-21 C

4 RC81465

Filter, In-line Fuel (70 micron)

I

1 Figure 6-22 A

5 EN269654

Filter, In-line Fuel (10 micron)

I

1 Figure 6-22 B

NON-ROUTINE MAINTENANCE ITEMS

6 CO89649 Gauge, Air, Dry 1 9.5 #30

7

PR270548

Boot, Breaker Panel Mount 2 9.5 #49

8

263532

Fuse, 5 Amp 1 Figure 6-24 C

9 EL270936 Fuse, 5 Amp 1 Figure 6-25 D

10 EL41538 Fuse, 10 Amp 1 Figure 6-25 E

11 EL59018 Fuse, 15 Amp 1 Figure 6-25 F

12 270492 Breaker, 40 Amp Auto-Reset 1 Figure 6-24 A

13 CO269748 Gauge, Fuel / Hour Meter 1 9.5 #23

14 EL270483 Relay, 500 Amp (control panel) 1 9.5 #36

15 CO270157 Breaker, Circuit 240V/25A 2 Figure 6-26 B

16 270501 Relay, 40 Amp 3 Figure 6-26 E

(E

1

,E

2

,E

3

)

17 CO62617 Breaker, Circuit 20A 2 9.5 #28

18 RC46552 Valve Kit, Compressor Unloader - Low Pressure 1 Figure 6-4 C

19 RC21654 Valve Kit, Compressor Unloader - High Pressure 1 Figure 6-5 C

20 KIT1120 Valve Kit, Compressor Head (Valve & Gasket) 1 Figure 6-6

21 KIT1121

Rebuild Kit, Piston Ring and Cylinder

II

1 Figure 6-6

22 260818 Switch, Pressure (N.C. 10 psi) 1 9.10 #1

23 CO67609 Valve, Pilot 1 9.10 #5

24 DR270814 Belt, Poly-Link Compressor 2 9.2 #4

25 DR62184

Belt, Serpentine Generator

1 9.2 #5

I

Consult the Engine Operator’s Manual for additional information.

II

Consult Vanair

®

Service Department for maintenance on piston rings and cylinder procedures.

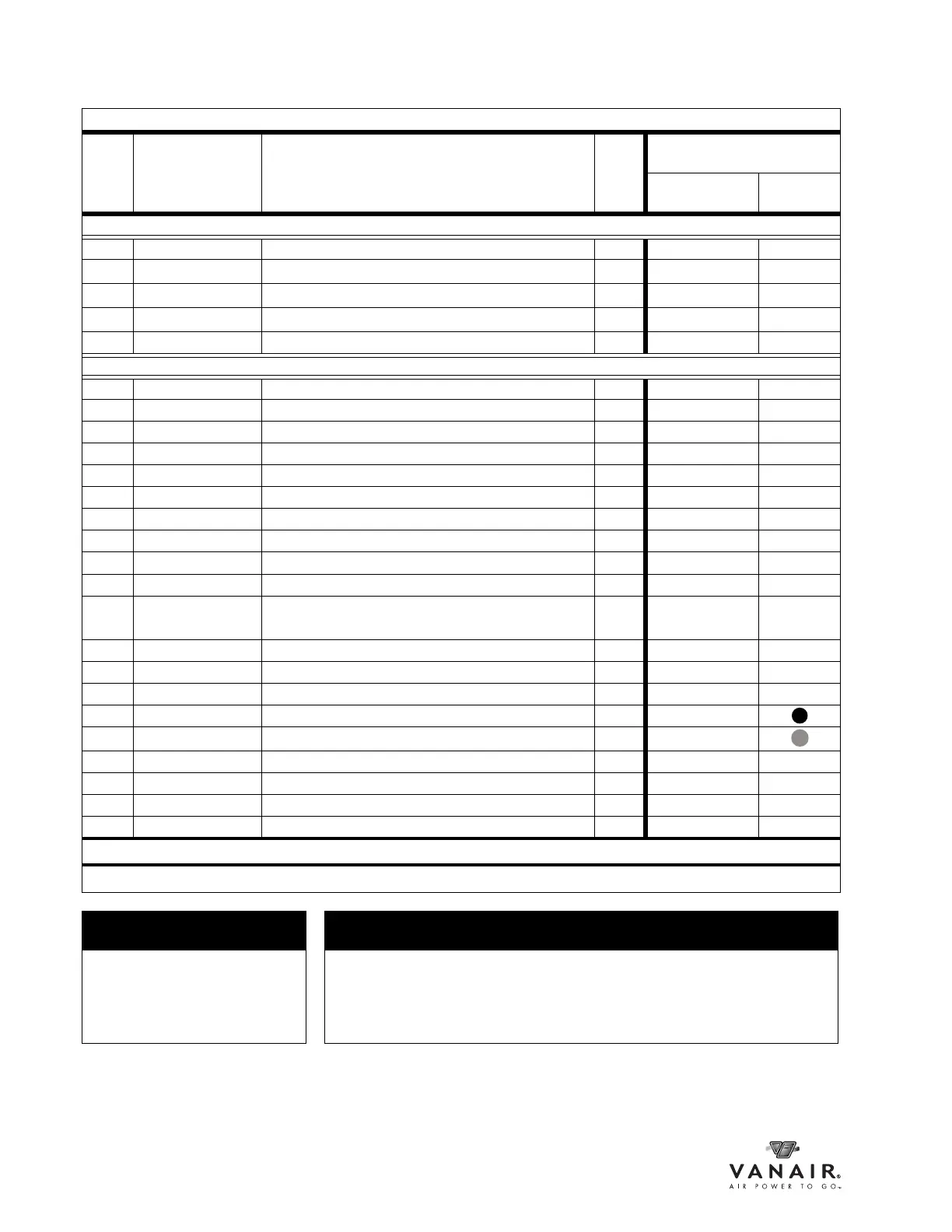

NOTE NOTE

For a complete list of available

options, see Appendix A,

Section A.5 Air N Arc 200

Series All-In-One Power

System Available Options List

If additional spare parts are being stored for future use, make certain that

they are stored in proper containers that allow for protection against

contamination, and kept in a clean area of moderate temperature reading.

For information on storing the machine package for periods of non-use,

consult Section 6.7.2, Long Term Storage.

Loading...

Loading...