AIR N ARC

®

200 SERIES ALL-IN-ONE POWER SYSTEM

®

SECTION 6: MAINTENANCE

090019-OP_r0 PAGE - 65

11. Dispose of worn air filter assembly within the

guidelines of all applicable local, regional

and/or federal laws.

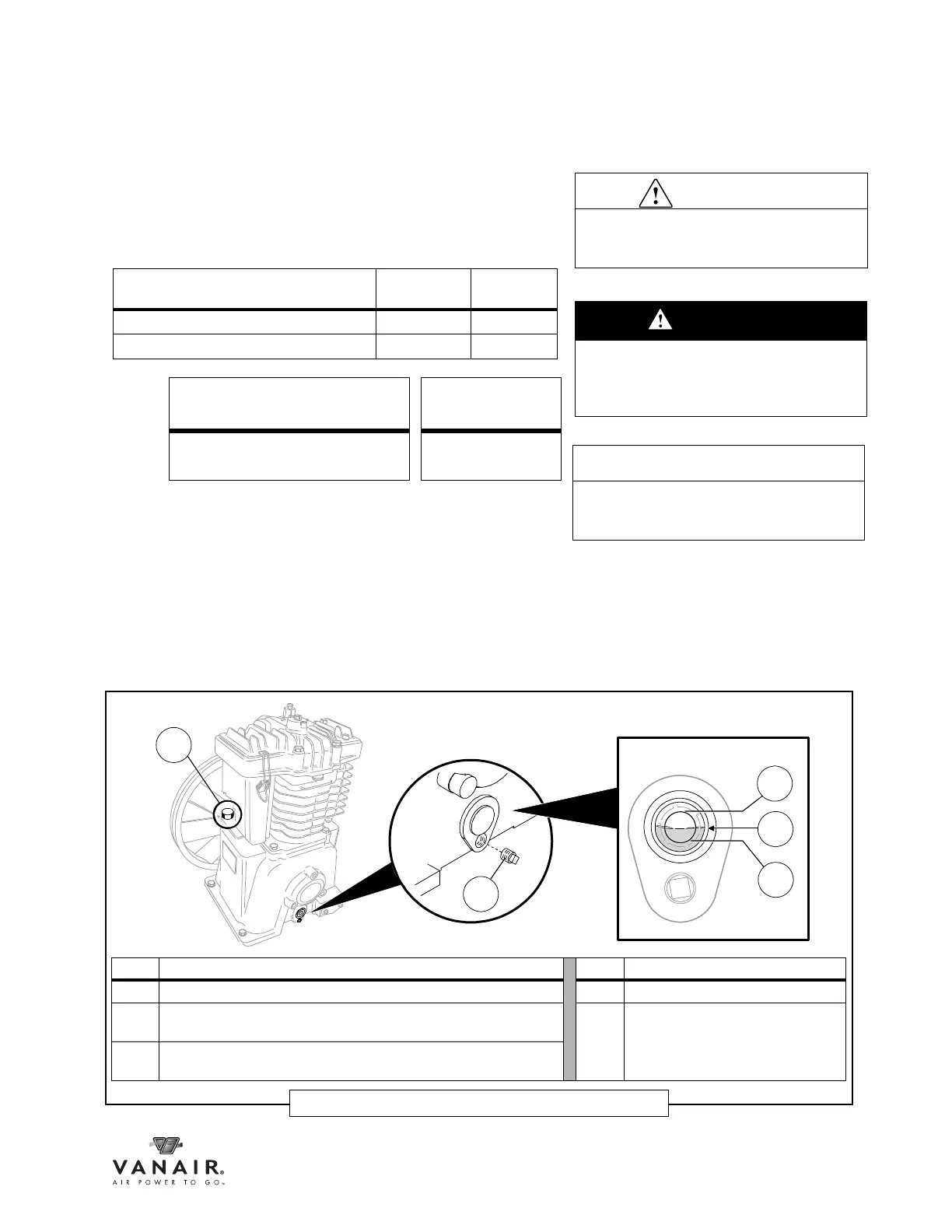

6.5.2 COMPRESSOR OIL MAINTENANCE

Consult Section 6.3, Maintenance Schedule Table for

compressor oil maintenance schedule, and refer to

Figure 6-2 and the following procedure to check the

compressor oil.

1. With the machine off, check the level of the oil

in the sight glass as indicated in Figure 6-2.

2. Locate the fill port [D]; unscrew and remove

the compressor oil fill cap.

System Operation Group Manual

Section

Location

Compressor Oil Maintenance 6.5.2 page 65

Compressor Oil Change 6.5.2.1 page 65

TOOLS/ITEMS NEEDED

REPLACEMENT

PART(S)

Compressor Oil (if necessary) ISO68, Non-

Detergent Oil

WARNING

Relieve pressure from the compressor

system before performing maintenance

on any components.

WARNING

Before performing maintenance or repair

operations on the machine, ensure that

all power has been removed and locked

out to prevent accidental start-up.

NOTE

The compressor is factory-filled to full

level (1.75 quarts) of high quality, non-

detergent ISO68 oil.

KEY DESCRIPTION KEY DESCRIPTION

A HIGH OIL LEVEL - Do not fill above the top of the red circle D COMPRESSOR OIL FILL PORT

B CORRECT COMPRESSOR OIL LEVEL - Midway of the sight

glass

E CRANK CASE DRAIN PLUG

(1/4” NPT)

C LOW OIL LEVEL - Do not let level drop below bottom of the red

circle

Figure 6-2: Compressor Oil Maintenance

Loading...

Loading...