SECTION 5: OPERATION AIR N ARC

®

200 SERIES ALL-IN-ONE POWER SYSTEM

®

PAGE - 48 090019-OP_r0

from the suitcase feeder into the positive (+)

welder connection port on the control panel.

2. Place the ground clamp from the suitcase

feeder and the ground clamp from the Air N

Arc 200 on the work piece.

3. Start the engine (See Section 5.2, Engine

Start-up and Shutdown Procedure).

4. On the control panel, place the DC Charger/

Welder switch in welder mode. Place the CC/

CV switch in CV mode.

5. Adjust the power dial on the Air N Arc 200 to

the appropriate voltage setting for the

material being welded. Adjust the power dial

on the suitcase feeder for the material being

welded. At anytime during welding, the

power dial may be adjusted to the desired

voltage level.

5.4.1.3 CV (CONSTANT VOLTAGE) MODE - USING

A SPOOL GUN

CV (Constant Voltage) Mode – commonly referred to as -

Wire Welding, MIG welding, or Gas Metal Arc Welding

(GMAW)

1. With the engine shut off, insert the twist lock

connection of the ground clamp into the

negative (-) welder connection port on the

control panel. Insert the power lead segment

from spool gun adapter into the positive (+)

welder connection port on the control panel.

NOTE

When using a spool gun, an adapter with

contactor must be used. Please consult

the spool gun manufacturer for

appropriate adapter.

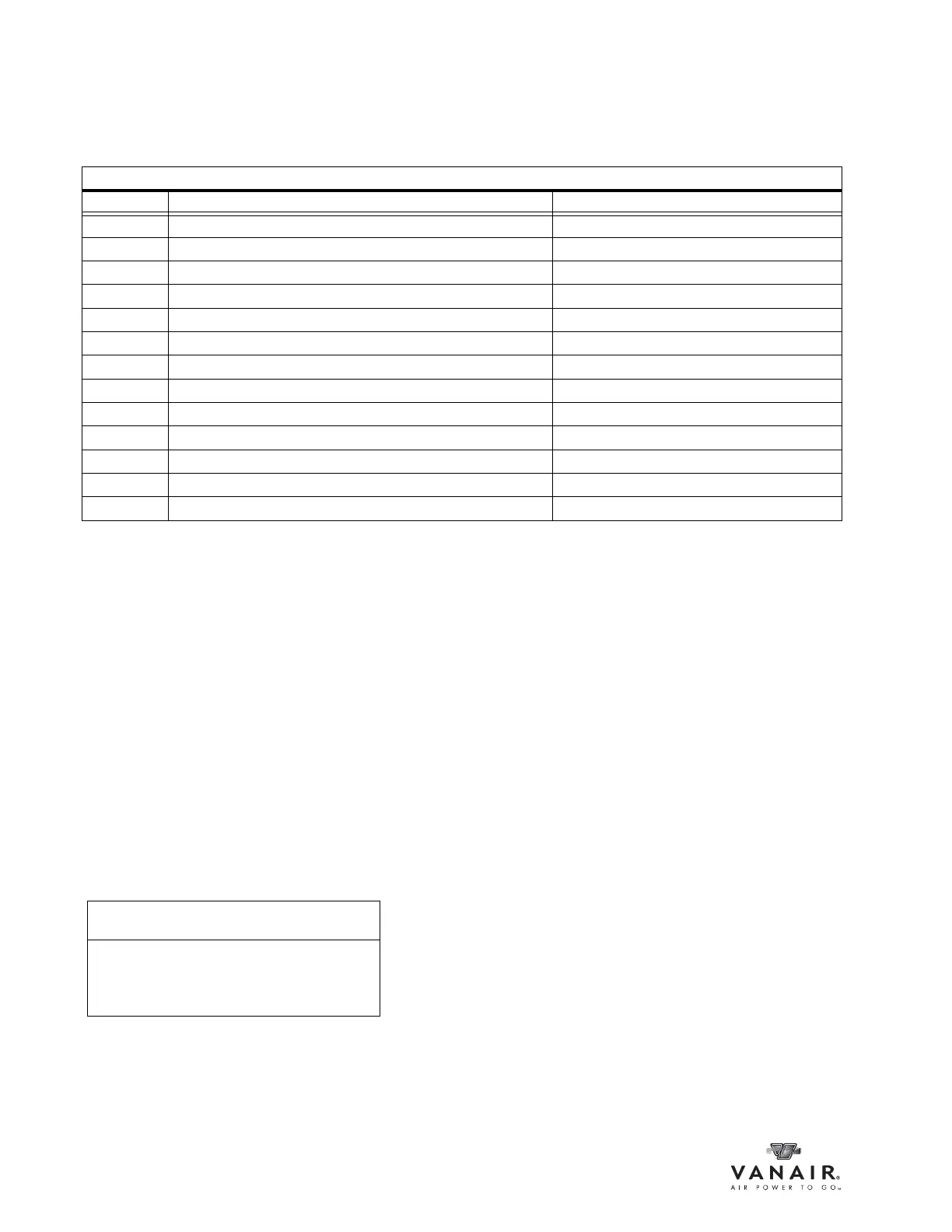

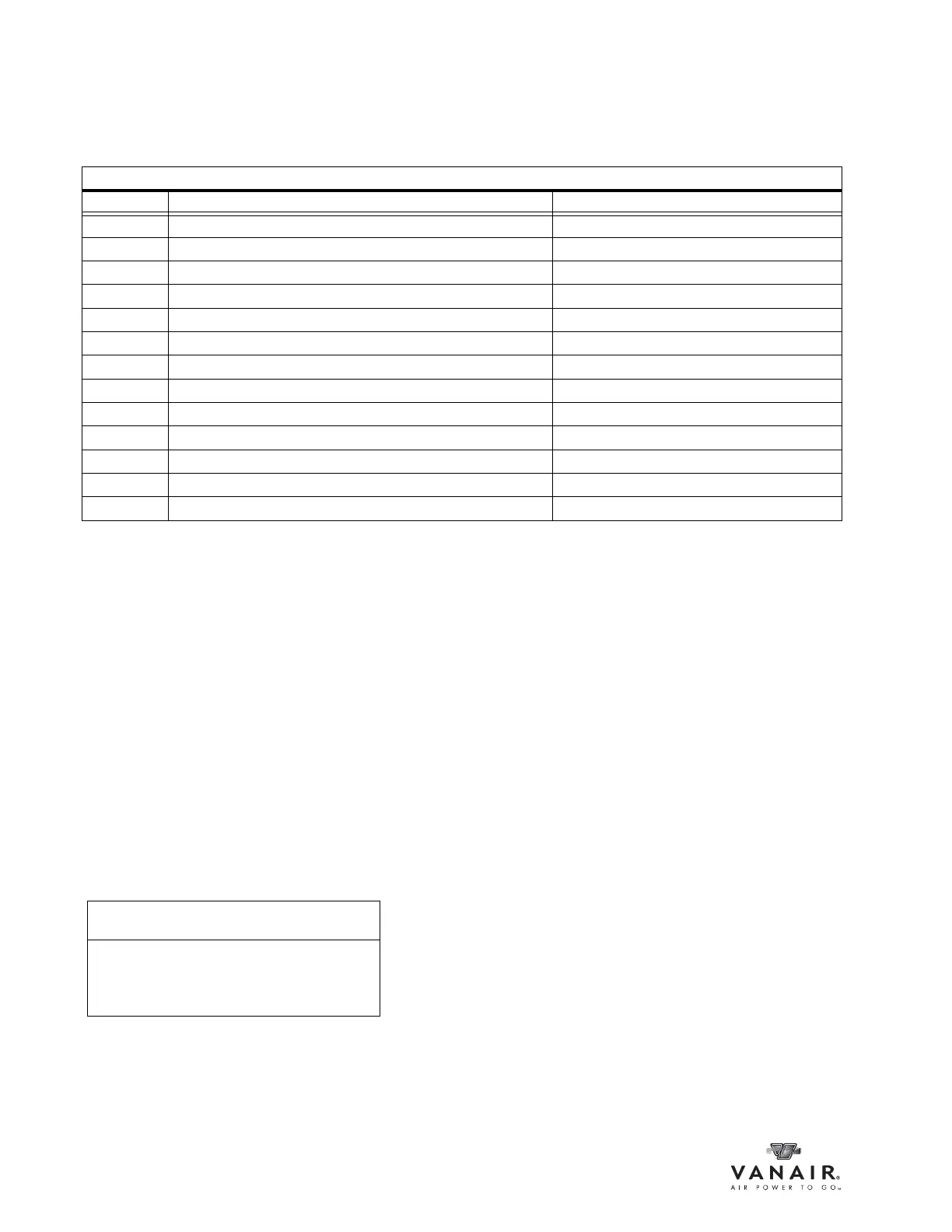

TABLE 5C: WELDING ROD TYPE, POLARITY AND FLUX CODES

DIGIT TYPE OF COATING WELDING CURRENT

10 High cellulose sodium DC+

11 High cellulose potassium AC or DC+ or DC-

12 High titania sodium AC or DC-

13 High titania potassium AC or DC+

14 Iron powder titania AC or DC- or DC+

15 Low hydrogen sodium DC+

16 Low hydrogen potassium AC or DC+

27 Iron powder iron oxide AC or DC+ or DC-

18 Iron powder low hydrogen AC or DC+

20 High iron oxide AC or DC+ or DC-

22 High iron oxide AC or DC-

24 Iron powder titania AC or DC- or DC+

28 Low hydrogen potassium iron powder AC or DC+

Loading...

Loading...