Series 65 MAINTENANCE

963283EA Edition 2019-05-03 105/

7.2 Maintenance procedures

Two maintenance procedures are defined for this valve. These are:

•

Replacement of isolation seals (gate and body seal of sealing ring) and valve cleaning

•

Replacement of actuator shaft seals

Required frequency of cleaning and replacement of seals is depending on process

conditions.

VAT can give the following recommendations for preventive maintenance:

Replacement of unheated

1)

heated

≤

80 °C

1)

heated > 80 °C

1)

(gate and

body seal of sealing ring)

12 month but max.

200’000 cycles

6 months but

max. 200’000 cycles

3 months but

max. 200’000 cycles

Those figures are reference values for clean conditions under various temperatures.

These values do not include any impact of the process. Therefore preventive maintenance

schedule has finally to be checked for the actual process conditions.

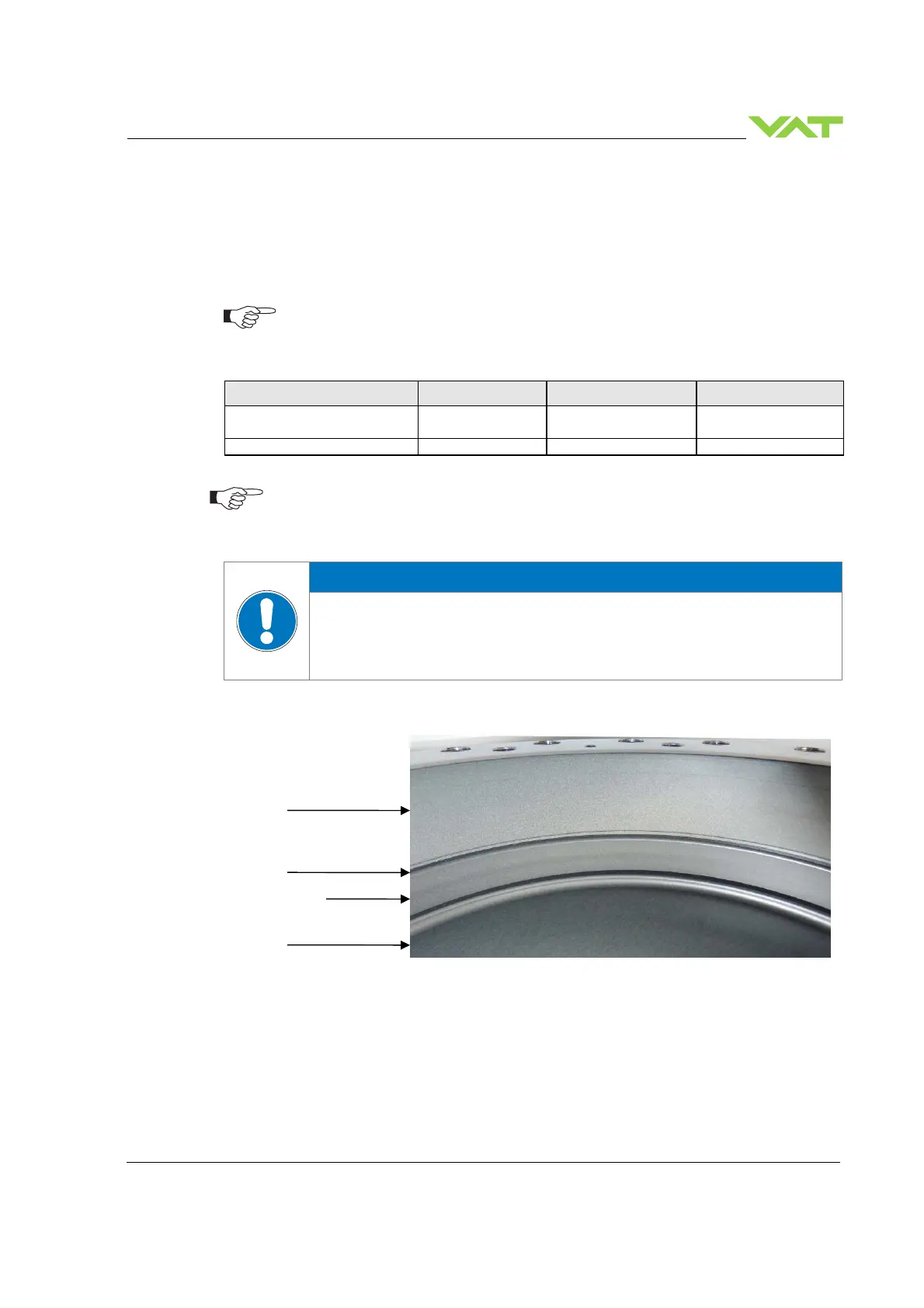

NOTICE

Vacuum grease

Vacuum grease may be distributed and contaminate the valve.

Prevent gap between body and sealing ring from air gun cleaning. Do not clean the

gap between body and sealing ring with compressed air.

See figure below:

Body

Gap

Sealing ring

Loading...

Loading...