Series 65 INSTALLATION

963283EA Edition 2019-05-03 25/

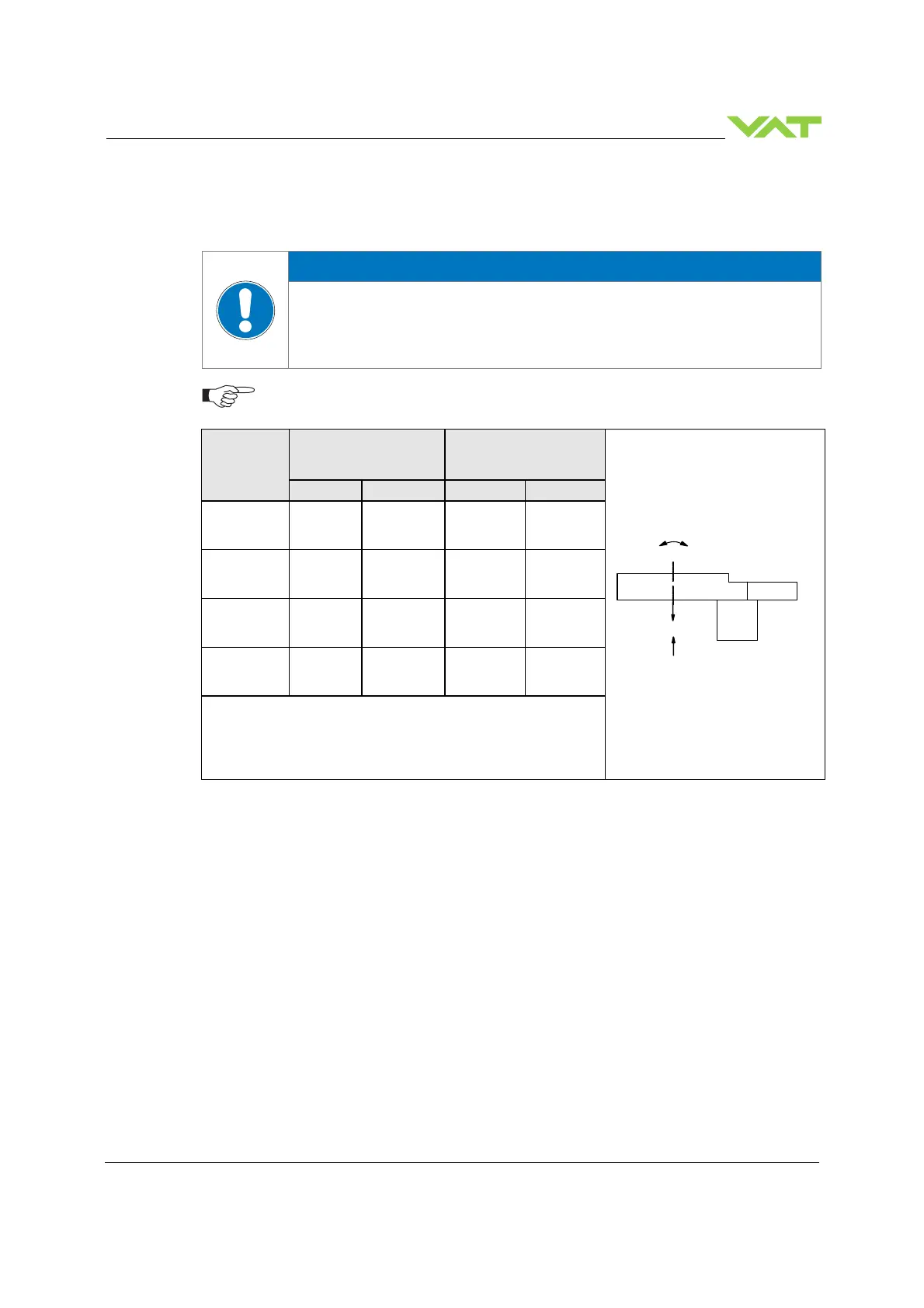

4.2.7 Admissible forces

Force at valve body

Forces from evacuating the system, from the weight of other components, and from

baking can lead to deformation and malfunctioning of the valve.

Do not higher force the valve body as specified.

The following forces are admissible.

Valve size

Axial tensile or

compressive force

«F

A

»

Bending moment «M»

N lb. Nm lbf.

DN100 / 4“

(65340 - . . . .

- . . . . )

1000 220 40 30

DN160 / 6“

(65344 - . . . .

- . . . . )

2000 440 80 60

DN200 / 8“

(65346 - . . . .

- . . . . )

2000 440 80 60

DN250 / 10“

(65348 - . . . .

- . . . . )

2500 550 100 75

For a combination of both forces (F

A

and M) the values are

invalid.

Verify that the depth of the mounting screws is min. 1 x thread

diameter.

Please contact VAT for more information.

4.2.8 Requirements to sensor connection

To achieve fast and accurate pressure control a fast sensor response is required. Sensor response time:

< 50ms. The sensor is normally connected to the chamber by a pipe. To maintain that the response time

is not degraded by this connection it needs to meet the following requirements:

•

Inner diameter of connection pipe: > = 10 mm

•

Length of connection pipe: < = 300 mm

These conductance guidelines must include all valves and limiting orifices that may also be present. Make

also sure that there is no obstruction in front of sensor connection port inside the chamber. The sensor

should also be mounted free of mechanical shock and vibration. Dynamic stray magnetic fields may

introduce noise to sensor output and should be avoided or shielded.

F

A

M

Loading...

Loading...