Series 65 DESIGN AND FUNCTION

963283EA Edition 2019-05-03 17/

3.2.1.1 Way of operation

The controller compares the actual pressure in the process chamber given by the pressure sensor

with the preset pressure. The controller uses the difference between actual and set pressure to

calculate the correct position of the control valve. The controller drives the control valve into the

correct position and the actual pressure again equals the set pressure.

This control operation is performed continuously. Pressure changes in the process chamber due to

leaks, desorption, and gas flow, reaction products, variations in pumping speed etc. are always

corrected at once.

3.2.1.2 Pressure control

In a vacuum system which is pumped and into which gas is admitted at the same time, the pressure

can be controlled in two ways:

1. Downstream control (standard):

The pressure is controlled by changing the conductance of a control valve between pump and

process chamber. This changes the effective pumping speed at the process chamber. Pressure

and gas flow can be independently controlled over a wide range.

2. Upstream control:

The pressure is controlled by changing the gas flow into the process chamber, while the pumping

speed remains constant.

3.2.1.3 Adaptive controller (standard)

A controller adapting itself to changes in pressure, gas flow and pumping speed without any manual

adjustments. This allows for a completely automatic operation of the system.

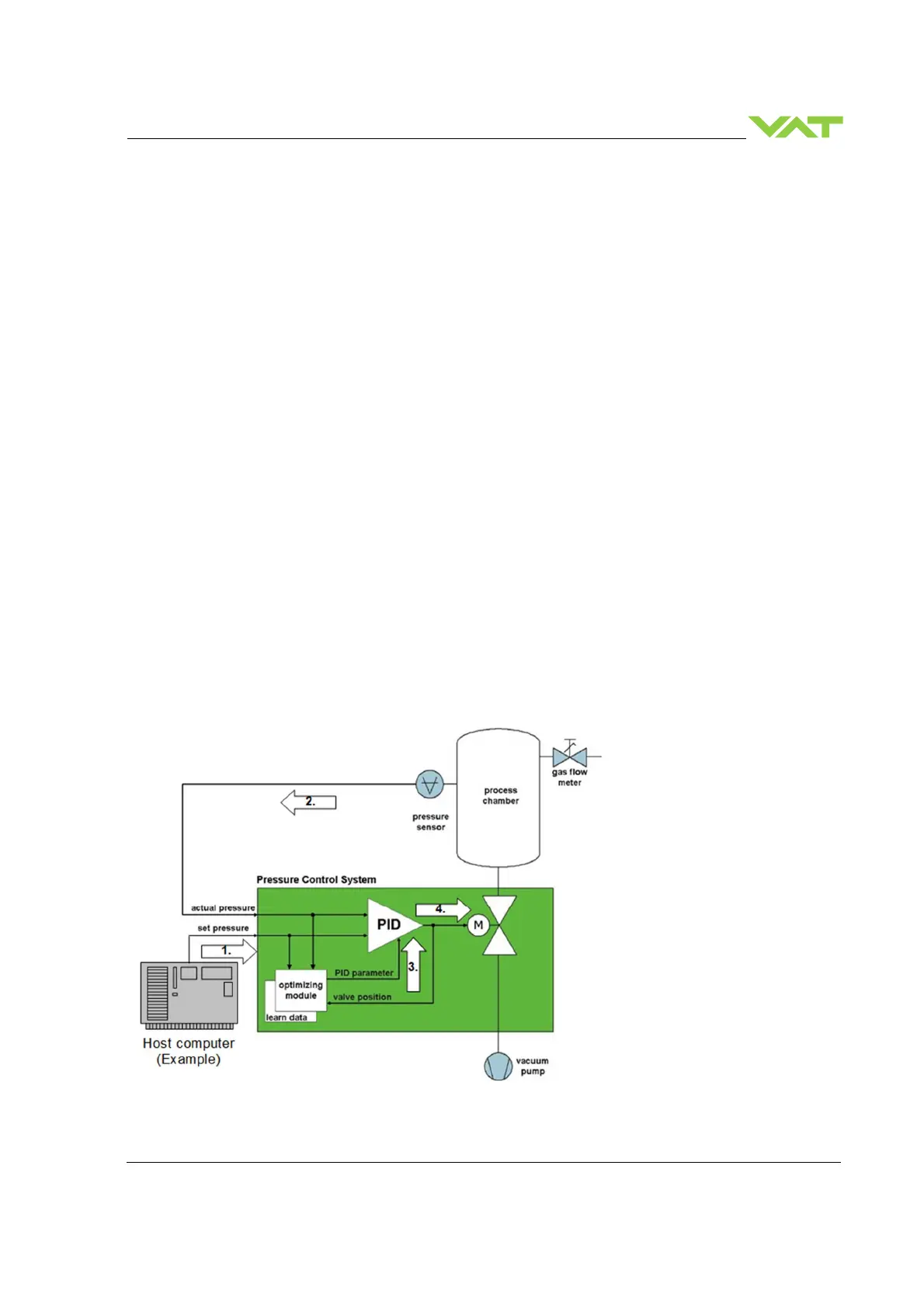

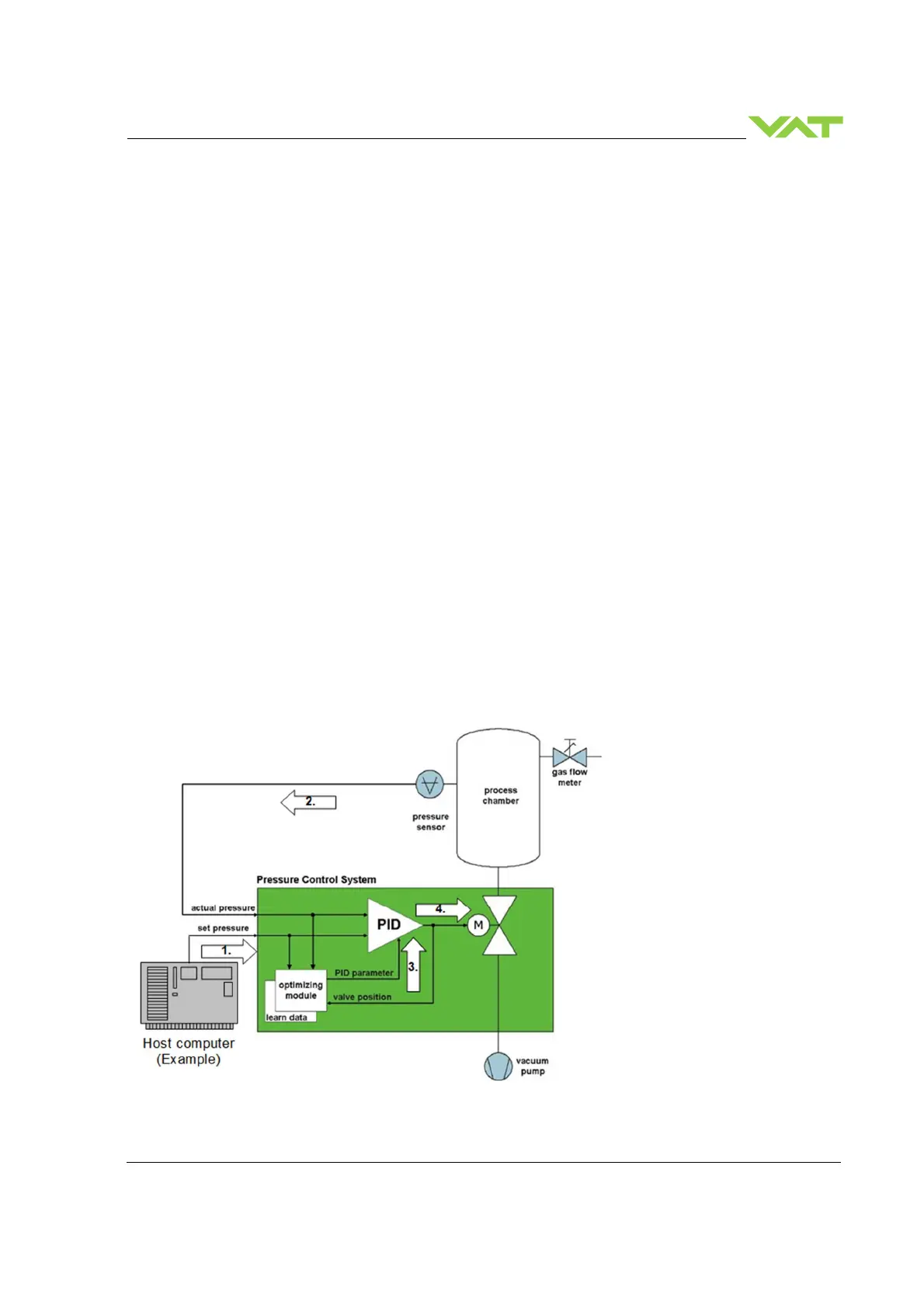

3.2.2 Principle of a pressure control system

1. Host computer sends

pressure set point

2. Controller reads actual

pressure from sensor

3. Optimizing module sends

new PID parameters

4. Actuator sets new valve

position

Loading...

Loading...