Installation 10

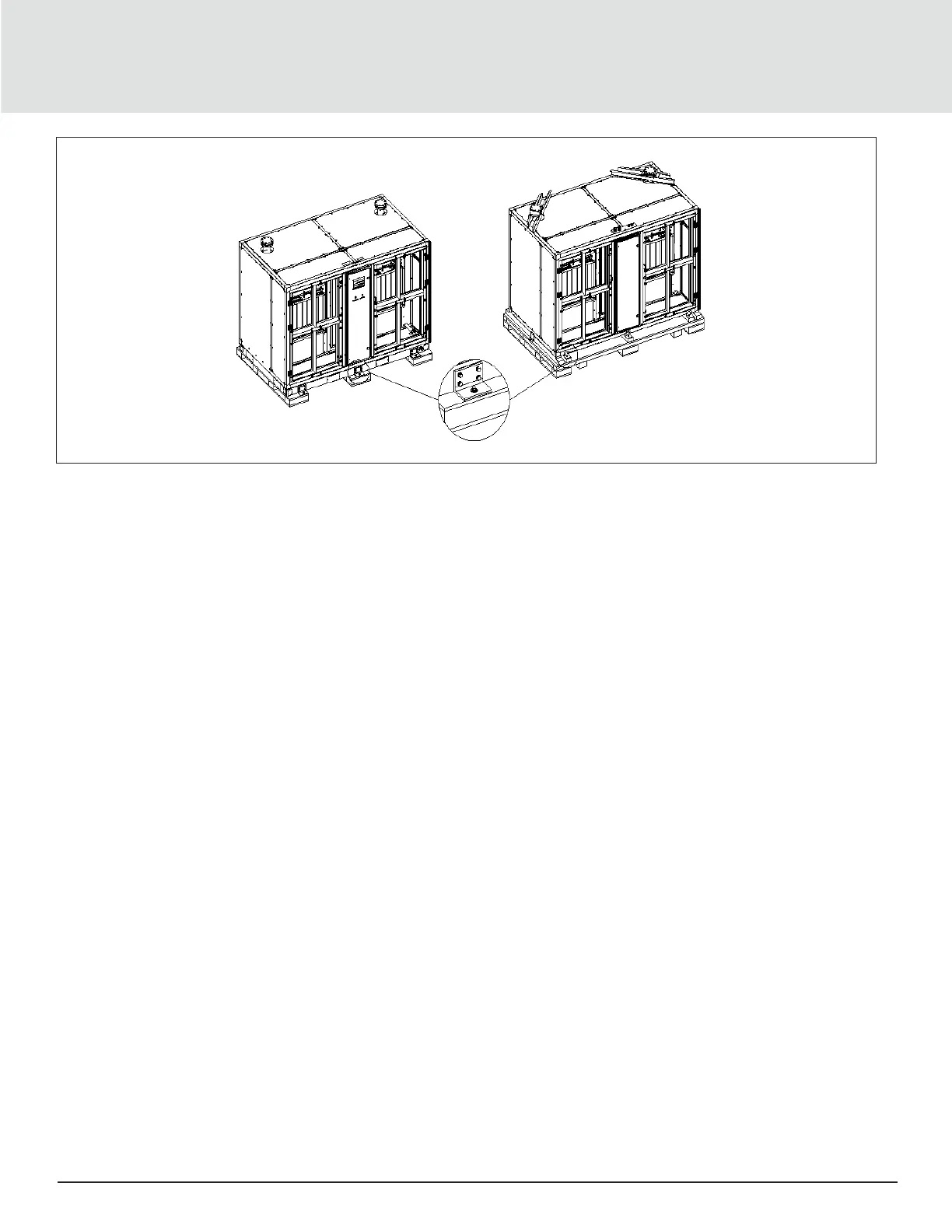

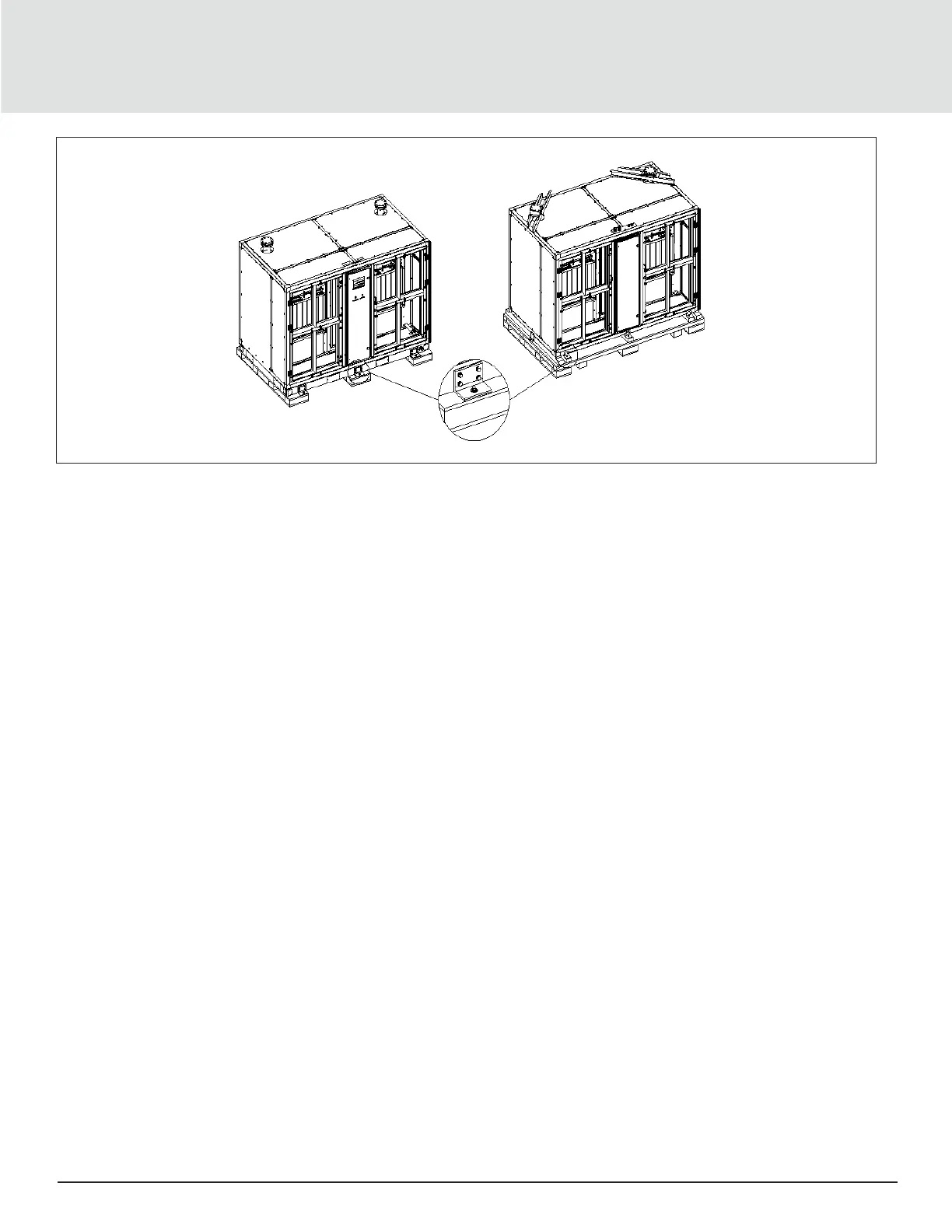

Figure 2-3 Pallet Screws Fixing Position

2.1.3. Inspection

Check that the fittings are complete and the components are intact against the packing list. If any parts are missing or

damage is found, please report immediately to the local oices of the carrier and Vertiv.

2.2. Installation Preparation (Site Preparation)

AHU is streamlined for maintaining a favorable environment for equipment rooms, computer rooms, and similar ecosystems.

Strict adherence to the installation procedures is mandatory to ensure that the air conditioner is installed properly.

2.2.1. Equipment Room Requirements

Before installation, the equipment room must be prepared to ensure a smooth operating flow and to achieve the expected

results. The equipment room must meet the standards, to get proper ventilation and heating. The design specifications for

the air conditioners must be ideal and should match the energy-eicient design standards.

Following are the requirements for maintaining a favorable room environment prior to installation:

• The room should have suitable and eective heat insulation.

• The equipment room should have a sealed damp-proof layer. Polyethylene film should be used for the damp-proof layer

of the ceiling and walls. Alternatively, moisture-proof paint can be used to simulate the same eect akin to Polyethylene.

Care should be taken that the coating on the concrete wall and floor must be damp-proof.

• Outdoor air significantly increases the load of heating, cooling, humidification, and dehumidification. Therefore, all the

doors and windows must be closed. Gaps and seams must be highly narrow to prevent the outdoor air from entering the

equipment room. It is an industry best practice to keep the infiltration of the outdoor air below 5% of the total indoor

airflow.

• Take appropriate thermal insulation and antifreeze measures for outdoor water pipes to avoid poor drainage and

insuicient water supply caused by freezing.

Loading...

Loading...