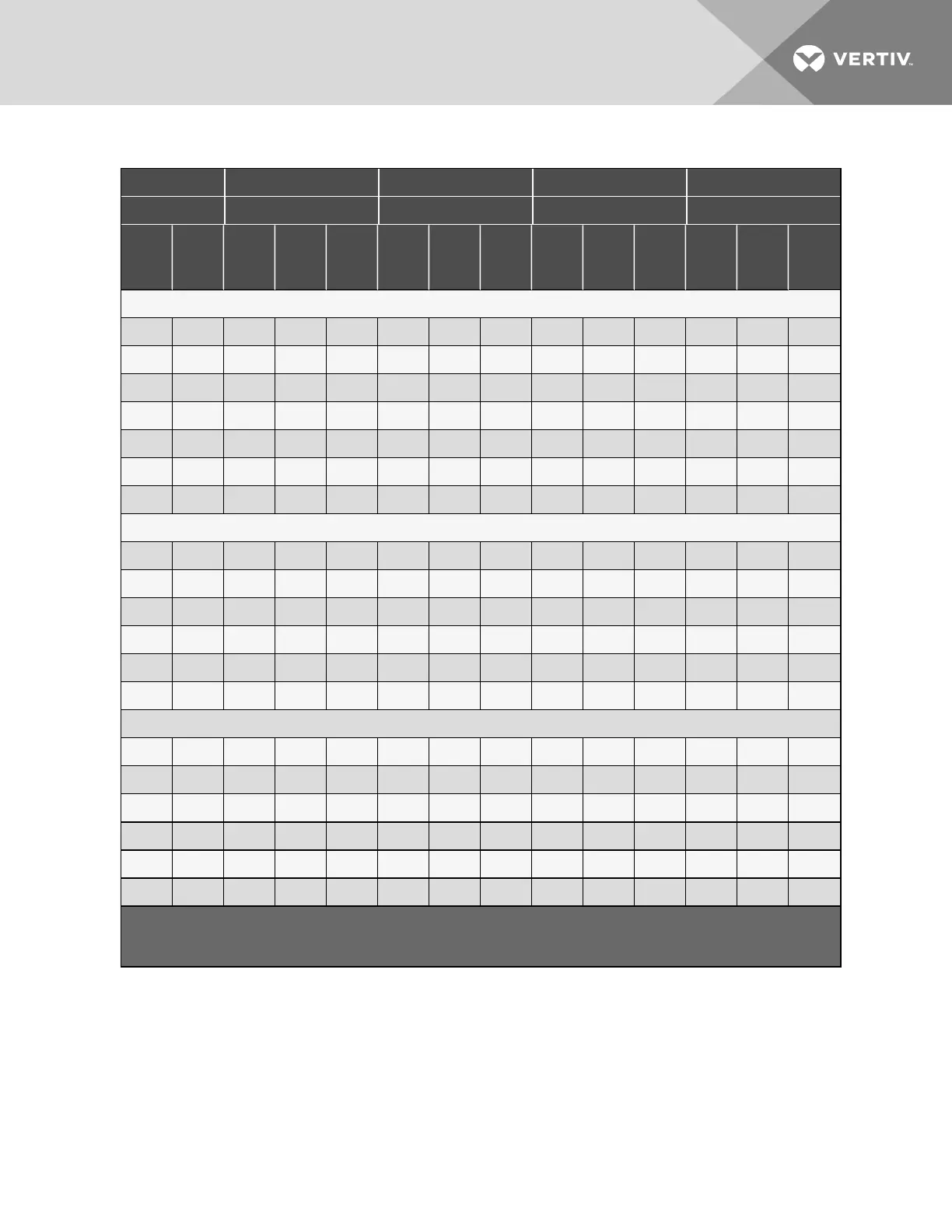

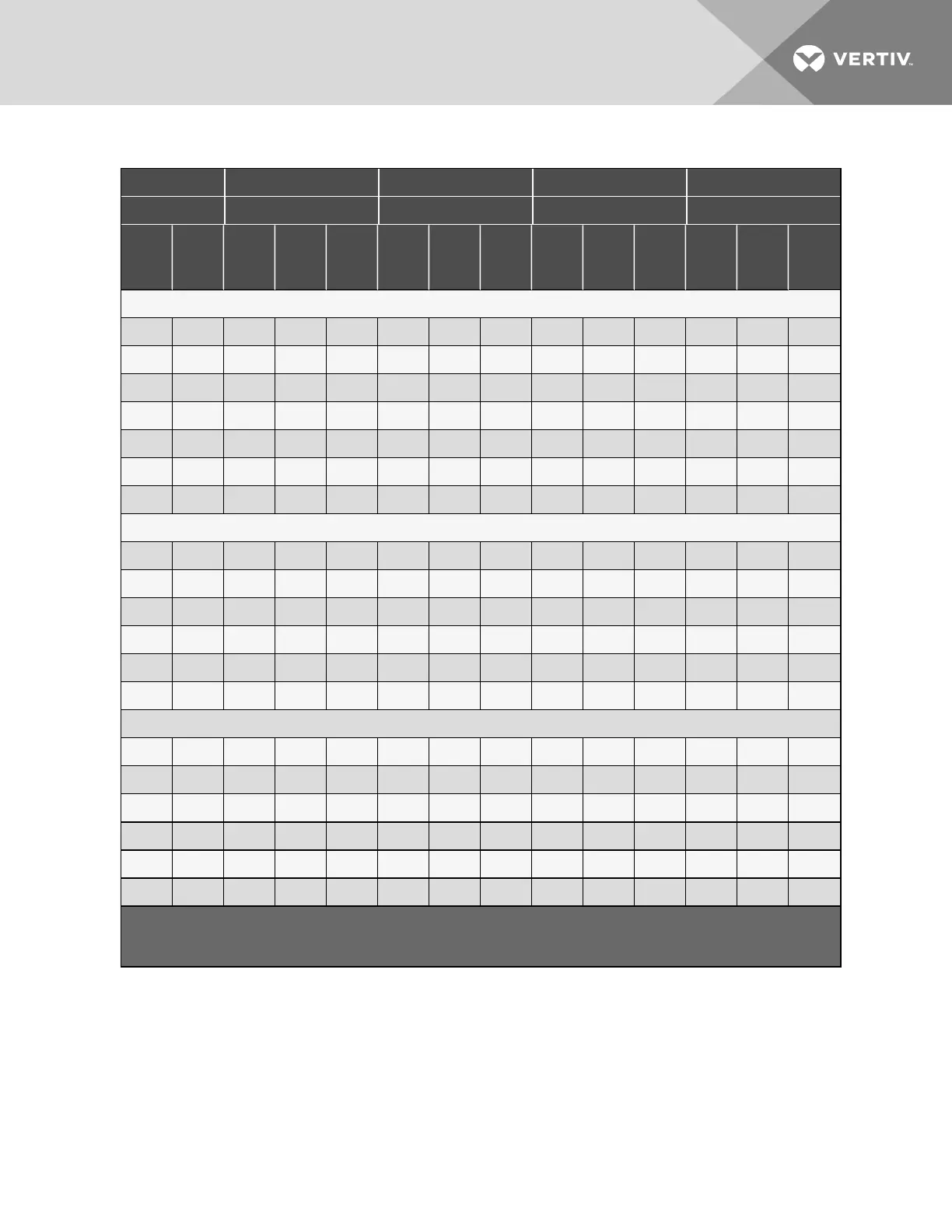

No. of Fans: 1 2 3 4

Model #: 33, 69, 092, 109, 112 139, 174, 197, 225 260, 310, 350 352, 419, 466, 491

Pump

hp

Ph

F

L

A

W

S

A

O

P

D

F

L

A

W

S

A

O

P

D

F

L

A

W

S

A

O

P

D

F

L

A

W

S

A

O

P

D

208/230/60

0.75 1 12.4 14.3 20 — — — — — — — — —

0.75 3 7 7.9 15 10.5 11.4 15 14.0 14.9 20 17.5 18.4 25

1.5 3 10.1 11.8 15 13.6 15.3 20 17.1 18.8 25 20.6 22.3 25

2.0 3 11.0 12.9 20 14.5 16.4 20 18.0 19.9 25 21.5 23.4 30

3.0 3 14.1 16.8 25 17.6 20.3 30 21.1 23.8 30 24.6 27.3 35

5.0 3 20.2 24.4 40 23.7 27.9 40 27.2 31.4 45 30.7 34.9 50

7.5 * 3 27.7 33.8 50 31.2 37.3 60 34.7 40.8 60

38.2

44.3 60

460/60

0.75 3 3.3 3.7 15 5.0 5.4 15 6.7 7.1 15 8.4 8.8 15

1.5 3 4.7 5.5 15 6.4 7.2 15 8.1 8.9 15 9.8 10.6 15

2.0 3 5.1 6.0 15 6.8 7.7 15 8.5 9.4 15 10.2 11.1 15

3.0 3 6.5 7.7 15 8.2 9.4 15 9.9 11.1 15 11.6 12.8 15

5.0 3 9.3 11.2 15 11.0 12.9 20 12.7 14.6 20 14.4 16.3 20

7.5 3 12.7 15.5 25 14.4 17.2 25 16.1 18.9 25 17.8 20.6 30

575/60

0.75 3 2.7 3.1 15 4.1 4.5 15 5.5 5.9 15 6.9 7.3 15

1.5 3 3.8 4.4 15 5.2 5.8 15 6.6 7.2 15 8.0 8.6 15

2.0 3 4.1 4.8 15 5.5 6.2 15 6.9 7.6 15 8.3 9.0 15

3.0 3 5.3 6.3 15 6.7 7.7 15 8.1 9.1 15 9.5 10.5 15

5.0 3 7.5 9.0 15 8.9 10.4 15 10.3 11.8 15 11.7 13.2 15

7.5 3 10.4 12.7 20 11.8 14.1 20 13.2 15.5 20 14.6 16.9 25

Values are calculated per UL 1995. Pump FLA values used are based on NEC tables for motor horsepower. OPD values may be adjusted higher than calculations to compensate for

maximum anticipated application temperatures.

* May require electrical component(s) with higher capacity in the drycooler. Consult factory representatives for assistance before ordering.

Table 6.4 60Hz Electrical Values—Standard Drycoolers with Integral Pump Controls, 1to4 Fans

6 Electrical Connections

43

Loading...

Loading...