a.

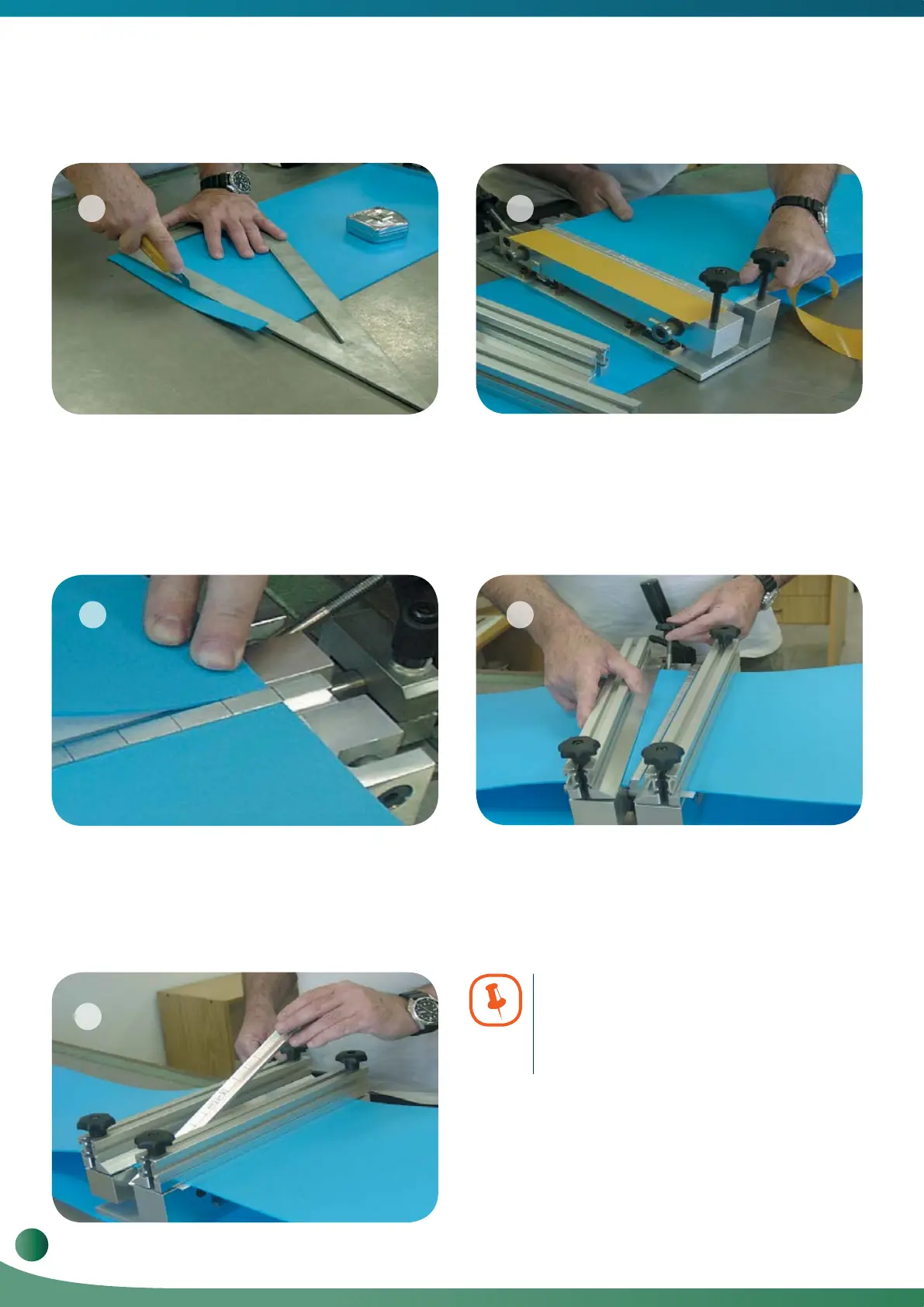

Cut the two ends of the belt at 90°. Ensure that the

cut is accurate and straight.

b.

c.

d.

e.

f.

Open the Pliers and remove the Locator Bar. Leave the

Pliers open The system is now ready for welding.

3.3. Preparing the Belt

Clean the belt ends with denatured alcohol. The

belt ends must be free of dirt and grease in order to

ensure a consistent, high quality weld.

Remove the protective paper from one piece of the

doublesided tape and place one end of the belt against

the Locator Bar in line with a reference mark. Press the

belt onto the tape to ensure good adhesion. There

should be no gaps between the belt edge and the

Locator Bar. Gaps will produce an inconsistent weld

and lead to early failure of the weld.

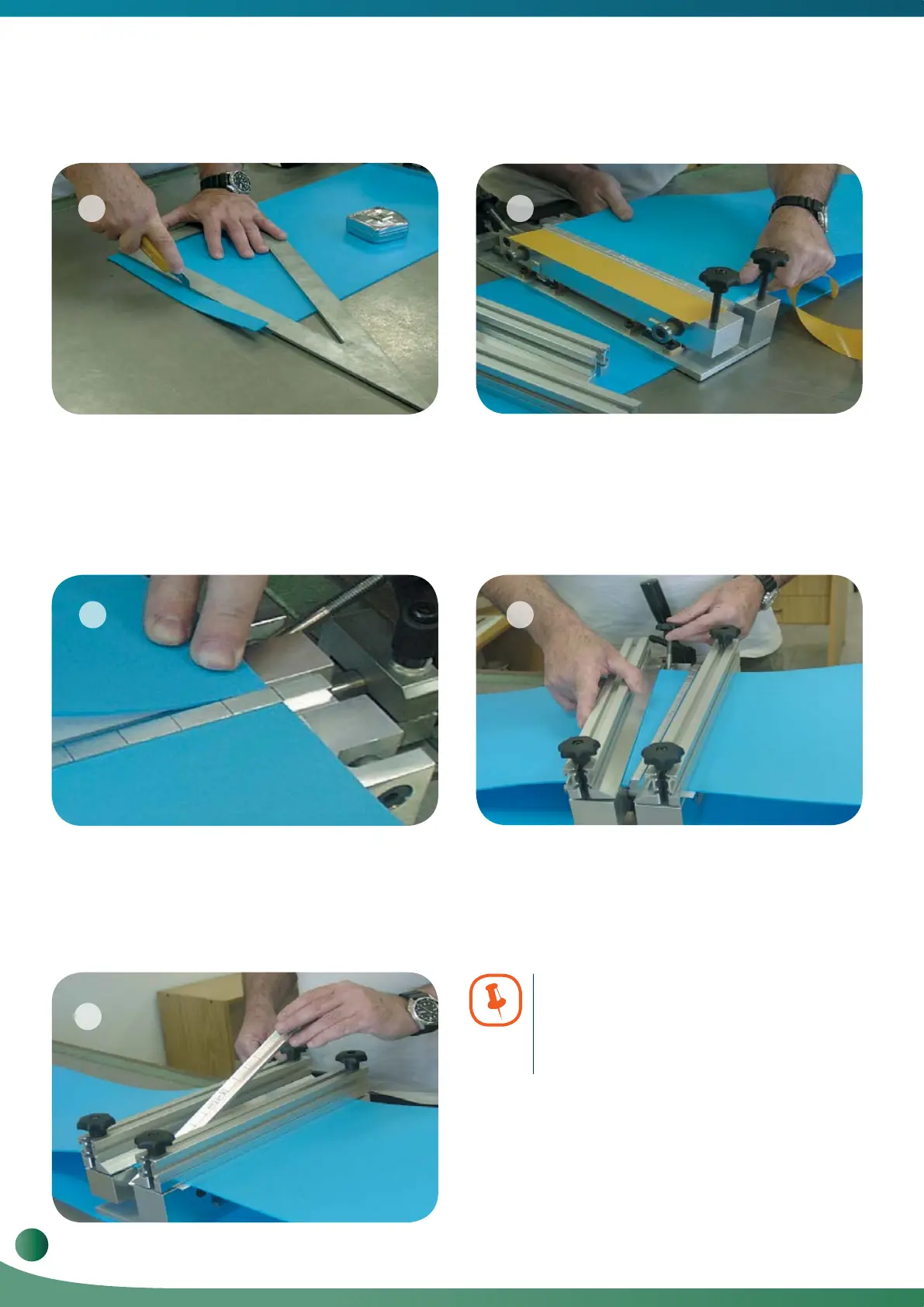

Repeat this procedure for the opposite belt end. Make

sure you align the edge of the belt with the reference

mark on the Locator Bar, to ensure a straight edge

between the two ends of the belt.

Set the Crossbars in place and swing the Locking Bolt

into position. Finger tighten the nuts. Be careful to

apply even pressure on Crossbars. Uneven pressure

will allow the belt to shift during welding and too much

pressure will cause the Crossbars to bend.

Note: If the belt is narrow in comparison

to the tool, add belt pieces to each side

of the belt to fill the gap. This will prevent

bending of the crossbar.

7

6

9

8

10

10

Volta Belting Technology Ltd.

Welding & Fabrication Tools FBW-Flat Butt Welding System Model II

Loading...

Loading...